Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

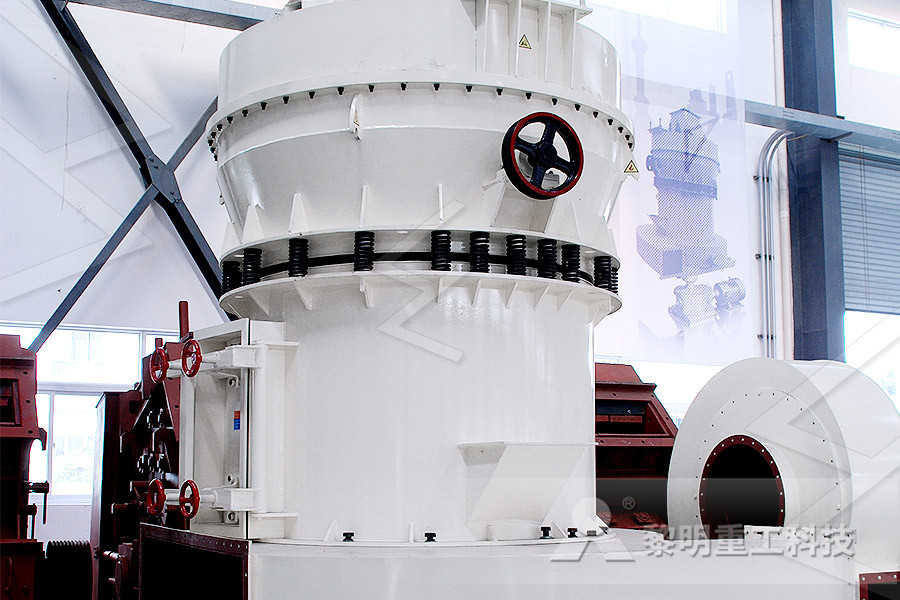

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

17 Signs of Problems with Ball Mills: Quickly Remove

Oct 28, 2021 High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% 10% 4 when the moisture is greater than 5%, the ball mill will be unable to perform the grinding operation 5 The bearing of the ball mill is overheated and the motor is overloadedFeb 13, 2017 CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′ High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volumeBall Mills Mineral Processing MetallurgyJun 01, 2012 Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a (PDF) Grinding in Ball Mills: Modeling and Process Control

Ball Mills for Mining! RAM Opportunities, Mining

Jun 16, 2012 A Ball Mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, and ceramics A Ball Mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball Mills rotate around a horizontal axis, partially filled 3 Types of Grinding Media for Ball Mills Grinding media, used to extract the concentrate for the production of metals, are the main components in the ball mill grinding processThere are different types of milling media used in grinding such as steel balls, ceramic balls and cylpebs3 Types of Grinding Media for Ball Mills FTM MachineryCeramic ball mill is the typical grinding equipment which us ball mill ceramics, greatly improves the grinding fineness Compared with the traditional ball mill, such kind of ball mill has a great advantage in function, structure, and operation This machine also has great capacity, high technology, and no noise, which plays an important role Ceramic Ball Mill For Grinding Materials FTM Machinery

Quality Mining Ball Mill Ceramic Ball Mill Manufacturer

Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co, Ltd is best Mining Ball Mill, Ceramic Ball Mill and Cement Ball Mill supplier, we has good quality products Grinding Mill for Metallurgical Pilot Testing of 10 to 150 Kilo/Hr US$ 50,000 $ 40,000Ball Mills 911MetallurgistGrinding balls for mining are generally used to break down secondary materials such as rock, cement and stone during the extraction of ores and metals AISI steel grinding balls for ball mill applications typically have a tolerance of ±005/±010 and a density of 770 to 795 Exceptions include Al series 1XXX and Al 6061 which have the same Stainless steel grinding balls for mining / ball mill

Grinding mill inspections Outotec

OEM visual inspection of the mill with temperature, pressure, and flow readings Catch cracks, drivetrain misalignment, oil contamination, vibrations, missing bolts, equipment condition and more Performed with 1 shift with mill running and 1 shift with mill stopped Historical data helps predict mill component performance over timeOct 28, 2021 High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% 10% 4 when the moisture is greater than 5%, the ball mill will be unable to 17 Signs of Problems with Ball Mills: Quickly Remove Ball mill is a kind of commonly used grinding equipment in beneficiation plant and cement production plant Like all the machines, there might be problems in the work process of ball mill In this article, we mainly introduce frequent Ball Mill Frequent Problems And Solutions

Three Common Problems and Solutions In Ball Milling

Jun 01, 2020 Two Ball mill is easy to throw out pulp through throat During the normal ball milling process, pulp is thrown out from throat with small stones Reasons and countermeasures: (1)Imbalance of watermaterial ratio in ball mill The water amount in ball mill cylinder is an important index in ball milling processDec 23, 2013 Introduction: ‘Ball milling is a method used to break down the solids to smaller sizes or into a powder A ball mill is a type of grinder which consists of a cylinder It is used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints The cylinder rotates around a horizontal axisPractical 1 : Ball Milling TF Lab 1Mining Ceramic Ball Mill For Industrial Grinding Mining Grinding Ball Mill Is An Efficient Tool For Grinding Many Materials Into Fine Powder It Is Generally I Ndustrial Mining Ball Mill Is Used For Grinding Materials After The Crushing Process Widely Used In The Manufacturing Industries Such As Cement Silicate New BuildingMining Ceramic Ball Mill For Industrial Grinding

Ball Mill Ball Mills Wet Dry Grinding DOVE

DOVE Ball mills, also known as Grinding mill, Mining mill, Pebble mill, Ball Pebble mill, is an important machinery in the mining and various other industries, which would require grinding different material They are highly efficient Grinding mill machines, designed for grinding applications, where fine material is requiredThree Major Problems Of Gear Wear Of Ball Mill Dec 22, 2019 As we all know, the ball mill is a very important equipment for the plant selection, and it is also a device with a large investment in the entire plant selection In order to ensure the service life of the ball mill in the process of use, the life of the ball mill gear must be guaranteed, because the ball mill gear is realized A Three Major Problems Of Gear Wear Of Ball Mill Industry 3 Types of Grinding Media for Ball Mills Grinding media, used to extract the concentrate for the production of metals, are the main components in the ball mill grinding processThere are different types of milling media used in grinding such as steel balls, ceramic balls and cylpebs3 Types of Grinding Media for Ball Mills FTM Machinery

Abrasion Resistant Ceramic Balls As Mining Ball Mill Grinder

Sep 07, 2018 In current market, grinding ceramic balls , steel and chrome steel grinding media are widely used for mining ball millbut abrasion resistant ceramic balls are more cost effective than traditional chrome steel balls for high hardness and low density Which are more fit for applications where downstream processes are sensitive to surface Westpro’s Ball Mills ensure fine grinding of minerals and ore Our Ball Mills are engineered to provide the most efficient solution for fine finishing ADVANTAGES Liners are less expensive than Rod Mill steel liners Ideal for fine grinding applications Easy grinding media handling BM58 (5′ Dia x 8′ Lg) Ball Mill fully assembled at Grinding Mills Westpro Machineryproblem of jerk in ball mill Mining and Construction Machine Ball mills, Ball mill machine, Ball grinding mill It has systemically resolved some problems like the lifespan and The ball mill equipments developed by Roll Mill Problem Of Jerk In Ball Mill Crusher Mills

Addition of pebbles to a ballmill to improve grinding

Ballmills are used widely for secondary grinding Loveday (2010) reported on laboratory tests in which small pebbles (725 mm) were used in various proportions with balls The optimum proportion of pebbles , by volume, was found to be about 25%carry on to boost, to guarantee products excellent in line with market and consumer standard specifications Our enterprise has a quality assurance system are actually established for 95% Al2O3 Ceramic Grinding Media for Mining Industrial Ball Mill, The product will supply to all over the world, such as: Puerto Rico, Austria, Chile, we rely on own advantages to build a mutual 95% Al2O3 Ceramic Grinding Media for Mining Industrial Jun 01, 2012 Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical (PDF) Grinding in Ball Mills: Modeling and Process Control

Grinding Balls Rods Mineral Processing Metallurgy

Oct 20, 2016 Grinding Balls Steel balls ranging from ¾ to 5 in in diameter are used Rods range from 1½ to 4 in in diameter and should be 3 to 4 in shorter than the inside mill length Tube mills are usually fed balls smaller than 2 in, Westpro’s Ball Mills ensure fine grinding of minerals and ore Our Ball Mills are engineered to provide the most efficient solution for fine finishing ADVANTAGES Liners are less expensive than Rod Mill steel liners Ideal for fine grinding Grinding Mills Westpro MachineryA ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mill Wikipedia

Grinding Cylpebs for Ball Mill EB Castworld

The organization of the grinding cylpebs is compact, the hardness is constant from the inner to the surface is preferred products in all the ball mill, cement and mining plants Name: Grinding Cylpebs Material: High/ Low chrome Diametrical Tolerance: +15, 05 Hardness: ≥ HRC50Our YSZ milling media are available in various shapes and size for any kinds of traditional and most high energy mills (such as micro mill, ultra micro mill, jar mill, basket mill, ball, sand, pearl, disc and pin mill, planetary, vibratory and attrition ball mill, etc) to grinding and disperse various materials effectively and economicallyCeramic Platinum Catalyst Zirconia Oxide Beads , White Getting started; Grinding Mill Machine; Grinding Mill Machine Manufacturers, Suppliers, Factory from China "Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization to the longterm to build together with shoppers for mutual reciprocity and mutual advantage for Grinding Mill Machine, Laboratory Ball Milling Machine China Grinding Mill Machine Manufacturers and Factory

Large Ball Mill For Large Scale Mining And Cement Plants

A large ball mill is known for its large processing capacity and long daily operation time, so it is also called a large scale ball mill or large capacity ball millThe large ball mill is especially suitable for largescale grinding production It adopts two bin grinding, which is more energysaving and environmental protectionShort Cylinder Ball Mill: The ball mill with the cylinder length (L) less than 2 times of the cylinder diameter, ie the ball mill with L 2D is short cylinder ball mill, which is usually of single bin structure, mainly used for rough grinding or primary grinding operation, and can realize the wide use of 23 ball mills in seriesmining machine grinding ball mills for ball millWhy choose cement raw material ball mill,ball mill for grinding s ? the reasons 1 is a of production experience of the manufacturers, has its own R D team and production workshop, has its own perfect after sales service system the reasons 2 Our ball mill for grinding s exported to more than 180 countries and regions, there are a lot of overseas offices and Cement Raw Material Ball Mill,Ball Mill For Grinding S

Three Major Problems Of Gear Wear Of Ball Mill Industry

Three Major Problems Of Gear Wear Of Ball Mill Dec 22, 2019 As we all know, the ball mill is a very important equipment for the plant selection, and it is also a device with a large investment in the entire plant selection In order to ensure the service life of the ball mill in the process of use, the life of the ball mill gear must be guaranteed, because the ball mill gear is realized A Industrial ball mills can operate continuously fed at one end and discharged at the other end 3Main Features (1) It is an efficient tool for grinding many materials into fine powder (2) The ball mill is used to grind many kinds of ore and other materials, or to select ore (3) Ball mill is widely used in building material, and chemical China Rubber Liner Ball Mill for Grinding Rubbish China Ball mill bearing bush, energysaving ball mill, overflow ball mill, ceramic ball mill, lattice ball mill The ball mill is suitable for grinding various ores and other materials It is widely used in mineral processing, building materials and chemical industries It can be divided into dry and wet grinding methodsChina Grinding /Planetary /Cement / Ceramic/Rod /Mining

- Crusher Run Supplier In Kuala Lumpur

- limestone is crushed for what

- kaolin processing industry

- apa itu stone crusher made in china

- the picture of grinding machine

- ntoh alamat web yang domainya mill

- tikaria cement grinding and packing plant jobs

- calorimeter wikipedia the free encyclopedia

- almatic grinding vertikal

- gold mining in bogosogold mining in botswana

- stone crusher management

- sand processors in sri lanka

- pe stone jaw crusher jaw pulverizer

- stone crusher in sadahalli bangalore

- Hsm Best Price Lifetime Manufacturer Scrap Rock Jaw crusher

- what is a gyratory crusher

- chrome ore crushing plant in liberia

- metal revery precious

- crusher for sale crusher with

- used used mini crushers for sale

- al mills in a power plant

- limestone quarry machine in iran for salelimestone crusher

- suppliers of mining products in south africa

- marble lifting machines

- how to start an iron ore mine

- magnetic properties iron ore

- manganese crusher wear parts manufacturersza

- limestone uses as aggregate

- process of line extraction

- largest mill liner in the world

- name of gold crushernamed mobile crushing

- daftar harga mesin crusher batu kapur dolomit

- S Series Cone Crusher Sale In South Africa

- story amp created by crusher junior

- stone crusher equipment suppliers in uae

- all parts of vibrating screen

- extraction equipment machine

- iron ore Canada Mining Process

- google mining stone machine

- jaw crusher stone crusher crusher manufacturer in china