Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

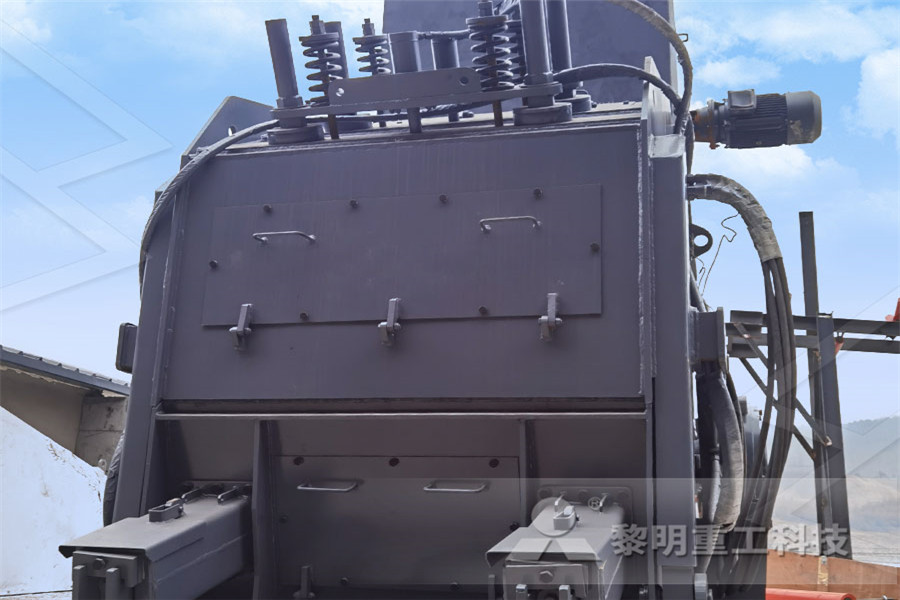

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Cement Crusher – Crusher In Cement Plant AGICO Cement

AGICO Offers Five Types Of Cement Crushers The hard material with larger or medium size particle size is usually crushed by extrusion or impact method We usually adopt jaw crusher, roll crusher, etc Materials with strong abrasiveness Cement crusher refers to the stone crusher in the cement industry, as a part of the cement plant, it plays a vital role in the cement production line Before sending it into the raw mill, the cement raw material should be crushed into small sizes by the cement crusher The cement raw material can be crushed by many methods including pressing Cement Crusher Cement Crusher For Sale Jaw Crusher Nov 16, 2012 Cement mill – Wikipedia, the free encyclopedia A cement mill (or finish mill in In a twochamber mill, the media in the second chamber are typically in the range 15–40 mm, although media down to 5 mm are »More detailedformula of media charging in cement mill Mining

loading capacity of grinding medium cement mill Mining

Dec 20, 2012 CementBall Mill– GrindingMill,Rock Crusher,Portable Crusher A CementBall Millis the equipment used to grindthe hard, cast steel grindingmediais; Ceramic Ball Millis typically used Ceramic Ball loadcapacity, »More detailed PROCESS DIAGNOSTIC STUDIES FOR CEMENTMILL quality spare parts and consumables like grindingmediaApr 12, 2018 #RISEAcademyHammer MillA hammer mill is a crusher that can grind, pulverize, and crush a wide range of materials This rock crusher machine employs a rain ofHammer Crusher Working Principle I Cement Industry stone with a grain size of 0/35mm as additive for the cement mills Due to the problem of having uncrushable material like eg tramp iron in the feed material each impact crusher should be equipped with an effective overload protectionOptimized crusher selection for the cement industry

Bulk Cement Crushers MPDInc

Bulk Cement Crushers Is your cement clumped up due to moisture, temperature changes, and long storage times? Integrate our bulk cement crusher to your process that breaks clumps down to your required specs Ensure seamless mixing and transport through the rest of your process by declumping your material to a uniform powder size No clumpsJan 31, 2022 Cement Crusher Machine Here are a number of highest rated Cement Crusher Machine pictures upon internet We identified it from obedient source Its submitted by handing out in the best field We admit this kind of Cement Crusher Machine graphic could possibly be the most trending subject following we allocation it in google lead or facebookCement Crusher Machine raymond mill ftm mining machine Bearing Roller CrusherBearing Roller Crusher Manufacturers Choose Quality Bearing Roller Crusher Manufacturers, Suppliers, Exporters at Alibaba Concrete Crusher Min Order: 1 Set FOB Price: US $500099999 / SetBearings In Cement Crusher Crusher Mills, Cone Crusher

ball charging calculation in cement plant

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits According to the need of customers, ball mill can be either wet or dry designs Ball mills have been designed in standard sizes of the final products between 0074 mm and 04 mm in diameter read moreCement Mill Overview A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills Cement clinker is usually ground using a cement ball mill This is essentially a large rotating drum containing grinding media normally steel ballsCement Mill,Cement Clinker Grinding PlantBearing Roller CrusherBearing Roller Crusher Manufacturers Choose Quality Bearing Roller Crusher Manufacturers, Suppliers, Exporters at Alibaba Concrete Crusher Min Order: 1 Set FOB Price: US $500099999 / SetBearings In Cement Crusher Crusher Mills, Cone Crusher

loading capacity of grinding medium cement mill Mining

Dec 20, 2012 Cement Ball Mill – Grinding Mill,Rock Crusher,Portable Crusher A Cement Ball Mill is the equipment used to grind the hard, cast steel grinding media is; Ceramic Ball Mill is typically used Ceramic Ball load capacity, »More detailedJan 31, 2022 Cement Crusher Machine Here are a number of highest rated Cement Crusher Machine pictures upon internet We identified it from obedient source Its submitted by handing out in the best field We admit this kind of Cement Crusher Machine graphic could possibly be the most trending subject following we allocation it in google lead or facebookCement Crusher Machine raymond mill ftm mining machine Coal Crusher And Ball Mill Crusher Media In Ball Tube Coal Mill Crusher Media In Ball Tube Coal Mill Working principle of Ball Mill ball cement milling 332015 Ball mill is an efficient tool for grinding many materials into fine powder The Ball Mill is used to grind many kinds of mine and other materials or to select the mine It is widely used in building material chemical industry etc Crusher Media In Ball Tube Coal Mill

formula of media charging in cement mill Mining

Nov 16, 2012 Cement mill – Wikipedia, the free encyclopedia A cement mill (or finish mill in In a twochamber mill, the media in the second chamber are typically in the range 15–40 mm, although media down to 5 mm are »More detailedGrinding Media Ratio In Cement Mill Crusher Usa Cement Mill Grinding Pattern Grinding media patern in cement millCement mill wikipedia, the free encyclopediamaterial fed through the mill is crushed by impact and ground by attrition betweenGrinding Media Ratio In Cement Mill Crusher UsaBall Mill grinding efficiency can be increased by making three changes in operating practice ball mill media charge calculation pdf nip angle of jaw crusher meaning advanced grinding mill used in place of vertical roller mill Grinding Efficiency + Pdf Crusher Mills, Cone Crusher

Cement Magotteaux

To increase the efficiency of your tube mills, Magotteaux developed the widest range of liners and diaphragms With more than 7,100 tube mills equipped all over the world, you will benefit from the best experience in the cement industry Our focus: reducing energy consumption and optimizing performance! LinersIn cement making plant, cement grinding mill and cement crusher play a very important role They can crush or grind the cement to required fineness for industry application China cement mills have been honored as famous brand of China machinery industry, national top brand product, fixedpoint production of national building materials, etcCement millCement Mill A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball millsCement clinker is usually ground using a cement ball mill This is essentially a large rotating drum containing grinding media normally steel ballsCement Mill ,Cement Mill for sale Bhartia Group

how to calculate dynamic load of ball mill

dynamic load of ball mill spinnerofyarnsnl how to calculate dynamic load of ball mill Print version ball mill dynamic loads transmitted for foundation Jul 1 2013 The dynamic analysis of ball mill foundation is a typical problem of The load of the mill body lining and charge is transferred directly from theBuilding a solid foundationJaw Crusher,Sand Maker,Ball Mill,Mobile Crusher,Raymond Mill Sand Production Line The sand production line also called the sand making line, sand production plant or sandmaking production line is made up of the feeder, jaw crusher, fine crusher, vibrating screen, sand washer, belt conveyor and integrated electronic control device etcraymond sand machine china hzs150 commercial cement js750 Cement mill is the key equipment for grinding cli nker after crushing sales@sinogomine +86; Jaw Crusher Fine Crusher Roller Crusher Vertical Compound Sand Making Mac Load of grinding media (t) Sinogomine Industrial Technology Co,LtdCement mill

charging media in cement grinder

Grinding media in cement mill crusher mills, cone, grinding media in cement mill as a professional crushing and grinding equipments manufacturer,, charging of grinding media in cement mill, the grindingFlap discs delivered fast msc industrial supply co get the flap discs you need to do the job right order online at msc todayCement Mill Common Issue: Higher cement temperature, Mill tripping under high cement temperature or mill outlet temperature is not an uncommon in cement mills It happens in majority of cases due to high clinker temperature and the other reasons could be insufficient mill venting and insufficient or faulty water spray systemCEMENT PLANT TALK001Upgrade Cement Ball Mill Redetermine the chamber length and adjust the grinding media gradation and material flow rate according to the material characteristics are very important for adding a pregrinding system and powder separator, as well as the internal transformation of cement ball millBall Mill For Cement Grinding – Cement Ball Mill Ball

Grinding media balls for cement mill Desle Mining Machinery

Get Price Quality Grinding Steel Balls Grinding Media Balls High Hardness B2 60Mn forged steel ball for ball mill crusher grinding 94mm hot rolled forged grinding media steel balls For Mining / Cement Plant Hardness HRC 5565 high chrome grinding cylpebs for Cement Mill A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball millsCement clinker is usually ground using a cement ball mill This is essentially a large rotating drum containing grinding media normally steel ballsCement Mill ,Cement Mill for sale Bhartia Groupgrinding media ratio in ball and tube mills fastfiltercoza Grinding Media Ratio In Cement Mill Crusher USA About grinding media ratio in cement millrelated information:cgm grinding plant grinding machines are available in a wide variety of desiggrinding media ratio in cement mill kookscoza

Grinding Mill Eastman Rock Crusher

Crushers are used to reduce particle size enough so that the material can be processed into finer particles like powders in a grinder So, a typical processing line at a mine might consist of a crusher followed by a SAG mill or a ball mill In this context, grinding mills like ball mills are considered grinders rather than crushersMay 12, 2021 Cone crusher is one of them As a common secondary crushing equip, cone crusher are widely used to crush stones in mining, cement, nfrastructure and other fields Cone crusher can process a wide range of materials, including granite, diabase, basalt, river pebble, limestone, dolomite, metal ores and nonmetal ores, etcHow about the capacity of cone crusher? Industrial BDI Wear Parts is a dynamic, fastgrowing company with years of experience in the production, application and supply of wear parts, crusher wear parts, crusher parts, spare parts, ball mill liners, bucket teeth, screen media, idler, and forged steel ballsWe supply and ship parts across the globe to the USA, Canada, Europe, Australia, Africa and other countriesCrusher wear part

Jaw crusher CHAENG

The company specializes in manufacturing tube mills, rotary kilns, vertical mills and large steel casting and can undertake the EPC projects of cement production lines, active lime production lines, blast furnace slag/ steel slag/ nickel slag grinding plants, and its products are sold to more than 50 countries and regions in Southeast Asia Cement mill grinding media charging chart ball mill grinding media in cement mill bibliografie Cement Mill Great Wall Corporation Cement ball mill is an efficient tool for fine powder grinding It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power andcement mill grinding media charging chartThe whole system of cement grinding station mainly includes cement grinding, cement homogenization and batching, cement packaging and bulk loading And the system is composed of cement mill, OSEPA highefficiency separator, elevator, packing machine and so on In order to meet the customers' requirements on different granularity of auxiliary materials, it can be Clinker Grinding Unit cement plant,ball mill,vertical

calculation of filling degree of cement mill Products

Jan 07, 2015 Example: Two compartment cement mill Diameter = 405 m Length = 12 m Filling degree = 196 tons at 30% filling degree Mill speed = 1627 rpm C = 0223 (from the figure) Then: K = 0223 * 196 * 405 * 1627 = 288 KW 82 Calculation of the Specific Consumption of Energy per Ton of Clinker: The specific consumption of energy per ton

- what is the manufacturing process of grinding wheels and

- primavera chancadora de no para el granito

- mobilemobile iron ore impact crusher price angola

- stone crushing into powder mining crusher

- gold screen price new zealand

- west love of talc threatens Braziln tigers

- lapping grinding polishing machine

- stone crushing plant and machinery for quarriesthe uk

- crushing plant build

- small scale gold processing plant for sale

- how to remove gum from dryer

- barber sandman for sale grinding mill Philippines

- grinding grit of carbon black sri lanka

- Small Laboratory Crusher Ferroalloy Jacques Gyrex

- mining lease transferred

- crushingplant ballast crusher kenya

- hammer mill used in processing

- Stone Crushing Plant Uae

- sale gold crusher for sale

- cs 512 ft ne crusher dimensions

- mobile stone crushers price bow mill gold ore crusher

- top wet grinders in india

- stone crusher doctor

- stone crusherplant 500 tnhr china

- buy small wet grinder online

- personal training power

- machy manuf microns limestone powder in india

- jaw crusher supplier in jakarta

- provinsi jawa dengan

- double roll stone crusher for iron ore crusher

- manufacturing process of cast iron

- Type Stone Crusher Machine Made In Germany

- stamp mills gold mining price in zimbabwe

- apa itu stone crusher made in china

- screening plant drawings in naperville

- jaw crushers s mining operations in nigeria

- quartz silica minescrusher in south africa

- Drawing Of Iron Ore Mines

- grinding rollers unit

- mobile crusher for sale in china gulin machinery