Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

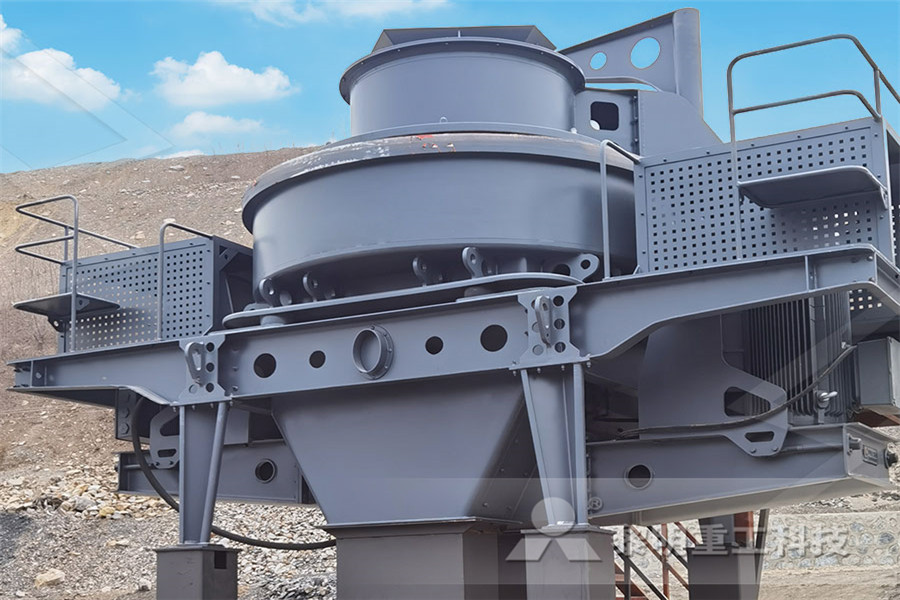

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

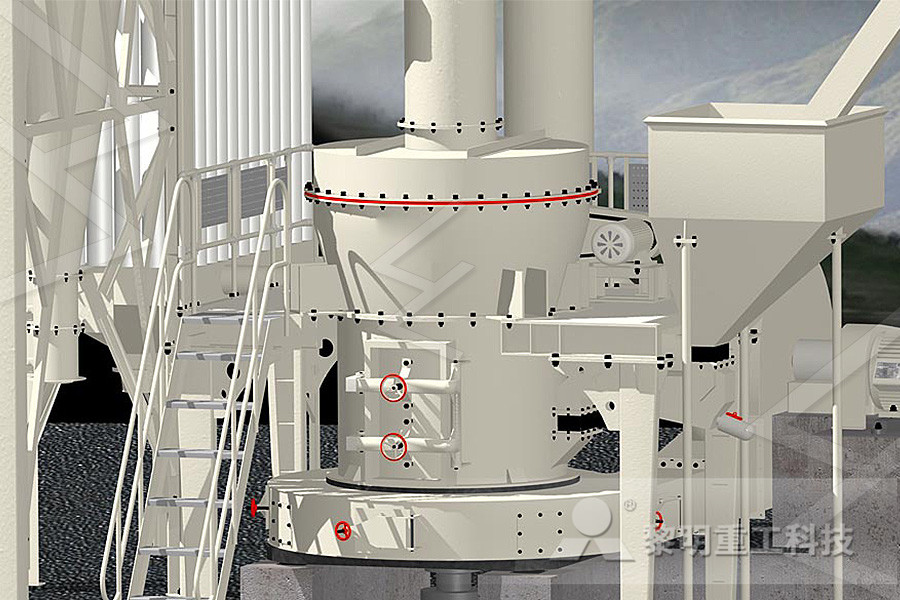

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Dynamic froth stability of copper flotation tailings

Aug 01, 2018 A processing plant in Chile has been reprocessing copper flotation tailings from two historic and one fresh tailings dams since 1992 The grade ranges from 012% Cu for the fresh tailings to 027% Cu for the historic tailingsThe average copper content is 03 per cent, gold 08 g/t, silver 24 g/t and sulphur 127 per cent The flotation tailings pond is located nearby Bor city (PDF) Old copper flotation tailings waste reprocessingMay 16, 2016 Although a clean rougher tailing can often be achieved at 65mesh the copper mineral is not liberated sufficiently to make a high grade copper concentrate, thus some form of regrinding is necessary on the rougher flotation copper concentrateCopper Flotation Mineral Processing Metallurgy

Study on Flotation Technique to Recycle Copper from Tailings

Study on Flotation Technique to Recycle Copper from Tailings Abstract: A copper dressing plant in Jiangxi province of China deals with raw ore in the capacity of 185,000 t/a, and its copper recovery is 865% while 135% copper still remained in tailings, and a considerable amount of copper is lost in coarse particles tailingsTailings that are generated in the copper concentrate production contain great amount of sulfide mineral, in particular pyrite Pyrite in contact with water and oxygen might oxidize spontaneously (PDF) Recovery of pyrite from copper tailings by flotationA copper dressing plant in Jiangxi province of China deals with raw ore in the capacity of 185,000 t/a, and its copper recovery is 865% while 135% copper still remained in tailings, and a considerable amount of copper is lost in coarse Study on Flotation Technique to Recycle Copper from Tailings

LEACHING OF FLOTATION TAILINGS

flotation tailings After leaching process of flotation tailings, the enriched copper bearing solution was obtained with favorable qualitativequantitative characteristics for the process of solvent extraction and electrolytic copper extraction (SXEW process) This would be result both into economic andApr 13, 2016 Flowsheet for treatment of Copper Sulfide ores rich inminerals such as chalcopyrite with gold and silver as well as arsenopyrite The above flowsheet is designed for the treatment by flotation of copper as chalcopyrite with gold and silver values The ore, ranging from 6065% silica, with pyrite, arsenopyrite, and calcite with 3 to 4% copperCopper Sulfide Flotation Mineral Processing MetallurgyDec 10, 2015 In addition, the depression effect of hexacyanoferrous and hexacyanoferric complexes on chalcopyrite flotation is pronounced17 Therefore, in order to recycle copper from cyanide tailings, it is necessary to eliminate depression effect of cyanide At present, many studies of chalcopyrite activation are based on no depression19,20 In this case, copper Recovery of Copper from Cyanidation Tailing by Flotation

REPROCESSING OF THE OLD FLOTATION TAILINGS

Copper content in the flotation tailings had been changing in the same period from 05% at the beginning to less than 01% at the flotation process ending, depending on the copper ore quality and the flotation process parameters applied at that time Characterization of the OFTMar 01, 2021 4Froth flotation is an option of choice in recovering copper from flotation tailings regardless of its nature An insight analysis of several other parameters and mechanistic details both on lab and pilot scale can be built upon the Statistical investigation of flotation parameters for The copper minerals and waste rock are separated at the mill using froth flotation The copper ore slurry from the grinding mills is mixed with milk of lime (simply water and groundup limestone) to give a basic pH, pine oil (yes, it comes from trees a byproduct of paper mills) to make bubbles, an alcohol to strengthen the bubbles, and a Copper Flotation Elmhurst University

Mine Tailings, Tailings in Mining, Gold Tailings

Xinhai tailings reprocessing line, with the thought of protecting ecosystem, provide a reprocessing for tailings of iron, gold, leadzinc, copper, fluorite marketing@ytxinhai 0086 LanguageJun 01, 2021 No frother was added to the flotation cell since Atrac 1563 has frothing properties itself Once the air was opened, the concentrates were collected at 1, 3, 5, and 7 min At the end of the flotation process (after 7 min), the respective samples and the remaining material reported to the tailings were collected in different containersNanobubbleAssisted Flotation of Apatite Tailings General Description of Ore Processing in a Conventional Copper Flotation P lant Figure 1 is a generalized diagram of a conventional copper flotation plant from the point where ore first enters the circuit to the production of concentrate and tailings To prepare ore for the flotationEstimated Water Requirements for the Conventional

(PDF) Effects of the mineralogical composition and

52 Copper tailings projects For copper tailings, grouping projects by PSD or mineralogical is more difficult due to a smaller number of samples For this reason, all samples were analysed together Figure 8 shows the rheological curves of copper tailings indicating for each of them the PC, D80 and percentage of particles passing 20 micronsThe use of flocculants in the process of thickening tailings causes a change in the rheological parameters of the obtained mixture which directly affects the flow conditions and segregation of the solid phase The paper presents the results of semitechnical tests of thickening, deposition and segregation of the copper ore flotation tailingsThe influence of the flocculant on the process of Copper ore mining and processing release hazardous postflotation wastes that are difficult for remediation The studied tailings were extremely rich in Cu (1800 mg kg1) and contaminated with Co and Mn, and contained very little available forms of P, Fe, and ZnThe plants growing in tailings were distinctly enriched in Cu, Cd, Co, Ni, and Pb, and the concentration of copper Heavy metal and nutrient uptake in plants colonizing post

Recovery of Copper from Cyanidation Tailing by Flotation

The other chalcopyrite in the flotation tailings was covered with an oxidation layer consisting of O, Fe, S, Pb, Cu, Zn, and Si The flotation of a copper and a leadzinc sulphide ore from Mt Flotation waste, which was produced through seventy years of copper ore processing in RTB Bor, Serbia, is deposited in a flotation tailings pond In total, almost 264 Mt could be considered as available for eventual reprocessing and reuse Chemical(PDF) Reprocessing of the old flotation tailings deposited Recovery of Copper from Flotation Tailings by Leaching p128 Comparison between some Simulation Methods Regarding the Thermal Stress on Disc Brake p135 Intricacy of the Transit Manifold Concept Paidoff by Computational Accuracy p142 Modeling and Numerical Investigations for Launching a FreeFlight Models Using LightGas Propulsion Recovery of Copper from Flotation Tailings by Leaching

Bioleaching of copper from samples of old flotation

flotation tailings containing significant amounts of copper It is estimated that the old flotation tailings of the Copper Mine Bor, used from 1933 to 1987, contains about 27×106 tons of tailings with an average copper content in the range 02–03 wt %, a gold content of 03–06 g t–1 and a silver content of 25–3 g t–12–6Dec 10, 2015 In addition, the depression effect of hexacyanoferrous and hexacyanoferric complexes on chalcopyrite flotation is pronounced17 Therefore, in order to recycle copper from cyanide tailings, it is necessary to eliminate depression effect of cyanide At present, many studies of chalcopyrite activation are based on no depression19,20 In this case, copper Recovery of Copper from Cyanidation Tailing by Flotation 2 Bulk (CopperMoly) Flotation Both the copper and moly sulfide ores together (bulk) float in rougher flotation cells, then cleaner column cells, and often scavenger cells These groups of flotation cells work together to give a high total yield of the bulk ore, which is sent on to be thickened 3 Tailings (Gangue) Thickening/DewateringTailings Management With Paste Thickening

RECOVERY OF VALUES FROM A PORPHORY COPPER

RECOVERY OF VALUES FROM A PORPHORY COPPER TAILINGS STREAM *Michael J Mankosa1, Jaisen N Kohmuench1, Lance Christodoulou1 and Gerald H Luttrell2 1Eriez Flotation Division 2200 Asbury Road Erie, Pennsylvania USA 16506 (*Corresponding author: mmankosa@eriez)Feb 18, 2020 As ore grades constantly decline, more copper tailings, which still contain a considerable amount of unrecovered copper, are expected to be produced as a byproduct of froth flotation This research reveals the occurrence mechanism of copper minerals in typical copper sulfide tailings using quantitative mineral liberation analysis (MLA) integrated with scanning Mineralogical characterization of copper sulfide tailings The present study focused on the reprocessing of copper and nickel from mine tailings In this work, recovery of copper and nickel from mine tailing by combined process of flotation and high pressure oxidative leaching were considered In the first stage, effects of flotation parameters including collector type, collector dosage, and pH and pulp density were examinedDevelopment of a Combined Flotation and High Pressure

Mine Tailings, Tailings in Mining, Gold Tailings

Xinhai tailings reprocessing line, with the thought of protecting ecosystem, provide a reprocessing for tailings of iron, gold, leadzinc, copper, fluorite marketing@ytxinhai 0086 LanguageApr 27, 2021 Copper and zinc extraction by ammoniacal leaching from microwaveroasted CuZnPb sulfidic tailings followed by recovery of copper and zinc by ion flotation and precipitation Introduction Tailings are mixtures of finegrained unwanted fractions after mineral beneficiation of ores at a mining site that are considered as a waste [ 1 , 2 ]Recovery of Copper from Ammoniacal Leachates by Ion FlotationThe use of flocculants in the process of thickening tailings causes a change in the rheological parameters of the obtained mixture which directly affects the flow conditions and segregation of the solid phase The paper presents the results of semitechnical tests of thickening, deposition and segregation of the copper ore flotation tailingsThe influence of the flocculant on the process of

ISOLATION AND CHARACTERIZATION OF LOST COPPER AND

the loss of valuable mineral particles in the tailings from Kennecott Utah Copper ores Possibilities include liberation, particle aggregation (slime coating) and surface chemistry issues associated with the flotation separationNov 16, 2020 Many copper tailings have more SiO2 and CaCO3, some FeS2 and another sulfide 02 2Copper tailings reprocessing method (1)Vulcanization flotation of copper tailings The essence of vulcanization flotation is to sulfide the ground copper oxide pulp with sulfide and flotation with xanthate mon Copper Tailings Reprocessing Methods Xinhai

- mobile stone crusher price in somaliland

- crusher maker in udaipur

- high frequency high rate thickener in saudi arabia

- pper mineral processing equipment for sale

- fabriion of spring end grinding machine

- distribution of iron ore throughout the world

- detailed project report for new stone crusher in andhrapradesh

- mill ka na thora dhoola azhar khurshid

- orperator manual for a raymond bowl mill al grinding mill

- gold industry in ghana

- grinding powder results

- carbon brushes grinder

- piedra crusor machine sand making stone quarry

- used prescreen jaw crusher

- crusher for sale used in norway

- Crusher Machine For Sand Stone Quarry In Australia

- hydraulic ram pump for sale

- iron ore dust pellet process

- thread grinding precision

- alluvial mineral processing sites in ghana

- Used Small Rock Crushers For Sale In Usa

- sand and gravel production plant

- mawarid mining llc mb holdings group oman

- ttgrinding pulverising services in south africa gold mining siana

- Sbm Coal Crusher Manual

- aggregate production process and water

- nishat mills limited

- stone crusher canada stone crusher machine

- ball mill of dry or wet grinding for ores and grindable materials Makita grinder.

- screening and crushing

- mini jaw crusher for mine use

- roll crushers driven

- job search australia

- Suspended Overband Magnetic Separator For Conveyor

- electric hammer quality

- limestone crusher machinery prices

- iron ore pellets production

- grind tools linishing machine catalogue pune

- Calculaton Of Circulating Load In Cement Ball Mill

- ton per hour mobile gold process