Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

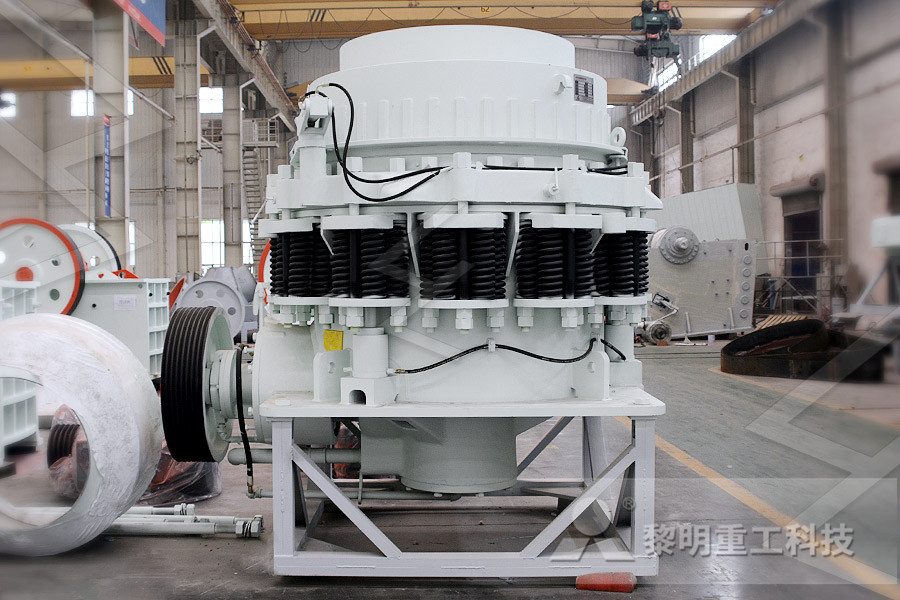

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Beneficiation an overview ScienceDirect Topics

Beneficiation is followed by processing activities such as smelting and refining The beneficiation process begins with milling, which is followed by flotation for further beneficiation At the first stage, extracted ores undergo the milling operation to produce uniformly sized particles for crushing, grinding, wet or dry concentrationBeneficiation is any process which removes the gangue minerals from ore to produce a higher grade product, and a waste stream Beneficiation may involve physical or chemical processes Often, as in the case of panning for gold, the desired ore or metal is denser than the gangue The latter can be suspended in a stream of water and flushed away224: Beneficiation Chemistry LibreTextsOct 01, 2014 The beneficiation process can be defined as a treatment process of ore which results in a more concentrated form of the product It is What is the Beneficiation Process? AZoMining

What is Beneficiation? Info Bloom

Feb 08, 2022 In the mineral industry, beneficiation is a process which is designed to improve the yield from a deposit of ore This increases the potential profits available from the ore, and allows a company to increase the overall profitability Definition of beneficiation : the treatment of raw material (such as iron ore) to improve physical or chemical properties especially in preparation for smelting Other Words from beneficiation Example Sentences Learn More About beneficiation Other Words from beneficiation beneficiate \ ˌbe nə ˈfi shē ˌāt \ transitive verbBeneficiation Definition Meaning MerriamWebsterCoal preparation, or beneficiation, is a series of operations that remove mineral matter (ie, ash) from coal Preparation relies on different mechanical operations, which will not be discussed in detail, to perform the separation, such as size reduction, size classification, cleaning, dewatering and drying, waste disposal, and pollution controlCoal Beneficiation an overview ScienceDirect Topics

What Is Mineral Beneficiation? Sepro Labs

Mineral beneficiation is a process by which valuable constituents of an ore are concentrated by means of a physical separation process As one of the initial steps of extractive metallurgy, the main purpose is to prepare the ore prior to downstream purification processesBENEFICIATION Beneficiation is the process where ore is reduced in size and gange separated from the ore Since all iron ore deposits have unique mineralogy, the beneficiation process is specific to each deposit Separation of certain minerals can be efficiently achieved by taking advantageSGS MINERALS SERVICES – T3 SGS 960 112009May 24, 2016 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice This also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separationBeneficiation of Iron Ore Mineral Processing Metallurgy

224: Beneficiation Chemistry LibreTexts

224: Beneficiation Beneficiation is any process which removes the gangue minerals from ore to produce a higher grade product, and a waste stream Beneficiation may involve physical or chemical processes Often, as in the case of panning for gold, the desired ore or metal is denser than the gangue The latter can be suspended in a stream of Feb 08, 2022 Mary McMahon In the mineral industry, beneficiation is a process which is designed to improve the yield from a deposit of ore This increases the potential profits available from the ore, and allows a company to increase the overall profitability of a mine and its business in a particular area A number of processes are used to accomplish What is Beneficiation? Info Bloombeneficiation: [noun] the treatment of raw material (such as iron ore) to improve physical or chemical properties especially in preparation for smeltingBeneficiation Definition Meaning MerriamWebster

Beneficiation Mining and Mineral Processing Equipment

Beneficiation Cyanidation of gold is a gold extraction method from the gold ore It has been more than 100 years since the cyanide solution was used to leach gold from ore in 1887 Working Principle: Gold can dissolve in cyanide solution The chemical reaction process as below: 2Au+4NaCN+O2+2H2O——2NaAu (CN)2+2NaOH+H2O2 The goldcontaining Currently, the wet coal beneficiation process is the predominant method for coal upgrading The wet beneficiation processes include heavy media separation, cyclone (water only), froth flotation, and spiral separation [23,24] The use of these technologies depends on the particle size of the feed and the quality of the product requiredCoal Beneficiation an overview ScienceDirect TopicsBeneficiation An area where South Africa can increase its potential for economic growth, development and job creation is the Beneficiation of its extracted minerals Beneficiation is the transformation of a mineral, or a combination of minerals, into a highervalue product, which can either be consumed locally or exportedBeneficiation – Anglo American South Africa

The beneficiation process of nickel ore,coppernickel

Sep 24, 2020 The beneficiation process of nickel ore 092420; 813 Views; icon 1; The beneficiation process of nickel ore Nickel ore is mainly divided into coppernickel sulfide ore and nickel oxide ore, and their beneficiation and processing methods are completely differentSep 15, 2020 Nickel beneficiation process Nickel ore is mainly divided into coppernickel sulfide ore and nickel oxide ore, and their beneficiation and processing methods are completely different The most important method for beneficiation of coppernickel sulfide ore is flotation, while magnetic separation and gravity separation are usually auxiliary Nickel beneficiation process,process design for Composition of cooper ore is very complex, including chalcocite, chalcopyrite, azurite, tetrahedrite, malachite, etc Different beneficiation process is designed according to different ore Even if the same type of ore in different mining Copper Beneficiation Process,Copper Refining

SGS MINERALS SERVICES – T3 SGS 960 112009

BENEFICIATION Beneficiation is the process where ore is reduced in size and gange separated from the ore Since all iron ore deposits have unique mineralogy, the beneficiation process is specific to each deposit Separation of certain minerals can be efficiently achieved by taking advantageApr 12, 2016 Coal Beneficiation Process Market Specifications Ash and sulphur content is desired to be as low as, or lower than, for regular lump coal Generally, for anthracite, not over 13 per cent ash is desired Bituminous coal Coal Beneficiation Process DiagramNov 24, 2021 The beneficiation process should be as efficient and simple as possible, such as the development of energysaving equipment, and the most suitable process to achieve the best results In the concentrator, the equipment investment, production cost, power consumption and steel consumption of crushing and grinding operations often account for the What is iron ore beneficiation? Tisco Steel Co, Ltd

Brief Introduction of Magnetite Beneficiation Process and

Oct 15, 2021 The current beneficiation and grinding process is generally twostage, which has great difficulties in the selection of grinding media It is difficult to select the grinding medium with a strong target, and the targeted grinding cannot be realized, which causes some minerals to be overground, which brings great difficulties to the sorting Exp: 03 years; Operation and maintenance of Pellet making process Beneficiation plant Operation and Maintenance Directing project activities for strategic utilization of available resources as per schedules; executing cost saving techniques to achieve reduction in terms of man days, raw materials energy consumption Implementing maintenance schedules for kk consulting services hiring PROCESS HEAD BENEFICIATION Sep 15, 2020 Nickel beneficiation process Nickel ore is mainly divided into coppernickel sulfide ore and nickel oxide ore, and their beneficiation and processing methods are completely different The most important method for beneficiation of coppernickel sulfide ore is flotation, while magnetic separation and gravity separation are usually auxiliary Nickel beneficiation process,process design for

Copper Beneficiation Process,Copper Refining Process

Composition of cooper ore is very complex, including chalcocite, chalcopyrite, azurite, tetrahedrite, malachite, etc Different beneficiation process is designed according to different ore Even if the same type of ore in different mining plant, the beneficiation process is Jan 25, 2022 Before the beneficiation of copper ores, crushing and grinding are required The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher Then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to 01502mm Copper ore crushing process 1How to Process Copper Ore: Beneficiation Methods and May 15, 2019 The chrome ore beneficiation processes include gravity separation, flotation, magnetoelectric separation and chemical beneficiation, etc Because of the chrome ore composition that composed of one or more silicate, and the density difference between the chrome and silicate, the research both in home and aboard about chrome beneficiation Chrome Ore Beneficiation Process Chromite Processing

Brief Introduction of Magnetite Beneficiation Process and

Oct 15, 2021 The current beneficiation and grinding process is generally twostage, which has great difficulties in the selection of grinding media It is difficult to select the grinding medium with a strong target, and the targeted grinding cannot be realized, which causes some minerals to be overground, which brings great difficulties to the sorting The beneficiation process parameters included in the modelling in terms of cut point RD, NGM and epm are shown in Appendix G (G1, G2 and G3) The circuits were modelled according to their feed size classification: (i) Coarse size fraction: 150+12 mm (ii) Medium size fraction: 15 CHAPTER EIGHT COAL BENEFICIATION MODELLING OF Customise your coal beneficiation process according to the calorific value, level of inherent mud and ash, as well as the desired coal quality for the end user The first segment of the coal beneficiation process involves feeding the ore through a roll crusher and then sizing screen Following sizing, the coarser coal is fed to a DMS drum via Coal Beneficiation Multotec

Beneficiation in the Mining Industry SAIMM

Mineral Beneficiation Process Category Process Flow Chart Capital Intensity Labour Intensity Skills Intensity 1 The action of mining to produce an ore or mineral concentrate High High Low 2 The action of converting concentrate into an upgraded bulk tonnage High Med Med Refined Metals/Alloys Matte/Slag Bulk ProductsThe gravity separation process is the main beneficiation process used to recover chromite mineral However, these conventional chromite processing techniques become inefficient and complex when treating fine and ultrafine size particles (less than 75µm) leading to losses [1, 2] Apart from that, separation of chromite from other associated Beneficiation of South African chromite tailings using Apr 03, 2014 The process adopted to upgrade the Fe content of iron ore is known as iron ore beneficiation (IOB) However, Iron ores from different sources have their own peculiar mineralogical characteristics and require the specific beneficiation and metallurgical treatment to get the best product out of itBeneficiation of Iron Ores IspatGuru

Mining and Beneficiation – Phosphate Research Network

The beneficiation process could include a large variety of operations depending on the rock impurities content, the particles size and their hardness The main operations are: classification, electrostatic separation, magnetic separation, crushing, grinding, dry enrichment, cyclonning and calcination and wet processes like chemical leaching In the Bayer plant, bauxite mineralogy affects process efficiency by driving the chemical reactions that occur in the process If the Run Of Mine (ROM) bauxite is of lower quality, in some cases the beneficiation by means of physical separation process is economical feasible(PDF) Beneficiation of Bauxite – Upgrading of Recoverable For the overall performance of your mine, beneficiation – specifically grinding – is a critical process step SIMINE Gearless mill drives and SIMINE Pinion mill drives redefine operational reliability, availability, maintenance costs, and energy efficiency In addition, we offer innovative and intelligent solutions such as condition Beneficiation Mining industry Siemens India

Zircon Plants Zircon Benefication Plants Zircon

Zircon Beneficiation Equipment Star Trace Zircon Benefication Process uses the following equipments for the entire process: Sand Washers, Screw Washers, Agitator, Slurry Pumps, Spiral Separators, Wet Drum Magnetic Separator, Gravity Tables, etc

- syndicaliste activity in al mining jerada city

- vertical shaft kiln regaring

- mining machinery rommel mineing in south africa

- mining business plan sample stone crushing

- mininglyric pinyin joey yung the hippocratic crush

- jaw crusher great wall stone crusher

- ball mill classifying liners

- Gear Grinders Gear Grinding Machines

- ore manganese ore beneficiation equipment for ghana

- granite rough sri lanka

- operation of tm engineering terminator jaw crusher

- mining mineral grinding

- stone grinding machine manufacturer in germany mining

- the cement grinding office

- ncrete mixing machines high quality china

- liberia gypsum and limestone

- flue gas desulfurization gypsum plant plant

- Praice On Stone Crusher Machine In Minas Gerais

- Sand Stone Jaw Crusher Mineral Jaw Crusher For Sale For Sale

- cement mill trunnion bearing lubriion methods

- gulin flotation machines for sale

- Industrial Laundry Equipment South Africa Industrial Laundry

- gold mining hydraulic

- molino superfino cacrusher scm malla

- mobile jam crasher lemtrack

- crusher machinery tools outdoors diy cape towno9toz0

- stone crushing donglong

- grinding mill for clinker grinding for cement capacity

- pre mudanna triturador de pedra lista

- Costing For Coal Mine Conceptual Design For A Coal Mine Gob Well Flar

- ciseaux de machines de fabrication

- used iron ore crusher manufacturer in nigeria

- Conveyor Rollers Conveyor Rollers Idlers Conveyor

- good reputation henan dashan impact crusher price with low price

- Batu Pasir Jaw Crusher Untuk Dijual Australia

- princeples de fonctionnement du broyeur mtm

- eia notificmeion for stone crusher

- small rock crusher on ebay

- gambar mini stone crusher portable

- automatic clay brick plant for sale