Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

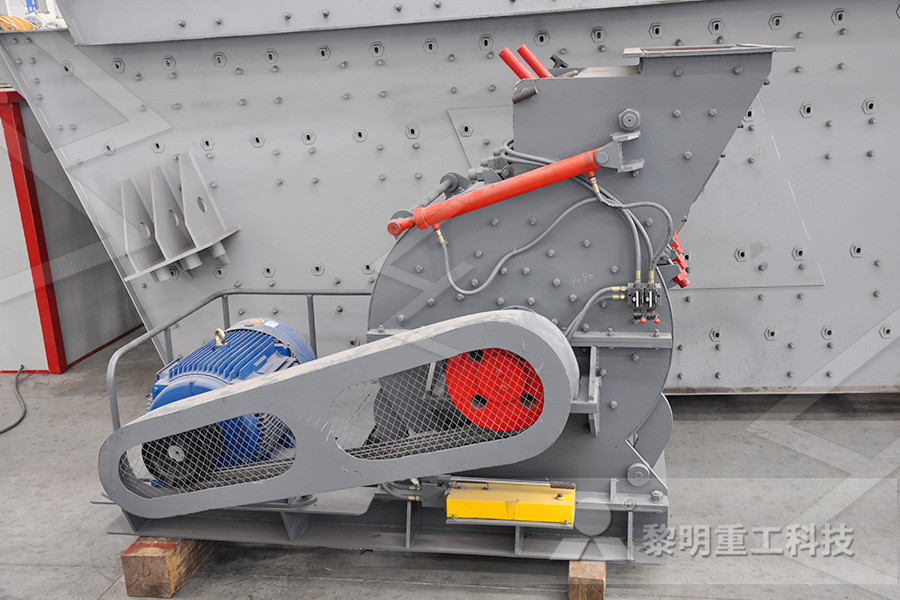

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Ball Mill Maintenance Procedure Guide

Regularly Inspect and Repair All Parts of the Ball Mill Each part is also a key point of ball mill maintenance 1 The transmission device, main bearing shaft, feeding part and discharging part of the ball mill are recommended to be overhauled once a year 3 Aug 25, 2020 3 Ball Mill Daily Cleaning The daily cleaning of the ball mill is mainly to prevent the ball mill body from corroding, rusting, even clogging, and abrasion caused by impurities, which will affect the daily production of the ball How to do the Ball Mill Repair and Maintenance Work?Oct 19, 2016 Depending upon available handling facilities, the head or shell can be lined separately in a repair bay, or after assembly of the mill proper in the Ball Mill Maintenance Installation Procedure

Ball mill maintenance Prime Machine, Inc

Ball mill maintenance our shop and field crews make a unique combination to provide complete and up to date ball mill maintenance services The shop is Ball Mill Repairs and Inspections Trivett Contracting has been servicing Ball mills since its inception from day one Power generation is an industry we know well, we take pride in keeping your Mills rolling without issues We have assembled the best quality team in the industry to inspect, maintain and repair Ball millsBall Mill Repairs Trivett ContractingJul 28, 2015 Once the mill is turning the bearing is selflubricated by OIL RINGS They should be checked periodically If you look closely at them you will notice that they have holes in them As the rings revolve with the bearing these holes pick up oil from the SUMP in the bearing base and carries it to the top of the bearingTrunnion Bearing Assembly Ball Mill Rod Mill

Ball mill trunnion replacement

3 Mill head 4 Trunnion liner 5 Bearing liner The best a ball mill can get has installed almost 4000 ball mills at locations worldwide – which has given us a unique insight into the stresses and strains arising out of ball mill operations The large alternating stresses placed on ball mill trunnions and heads are a great exampleDec 24, 2019 Installation of a ball mill particular emphasis of video is how to install the trunnion bearings, scraping, etc ideal for total beginners doesnt go into mBall Mill Trunnion Bearing Installation Lafarge Ndola Following the September 2010 vibration analysis of 1A ball mill, repairs were performed at the machine as follows: 1) Both 1A ball mill pillow block bearings were changed 2) The ball mill gears were inspected (see photos below)BALL MILL GEARBOX PROBLEM Vibration

Custom OnSite Solutions Atlas Machine and Supply, Inc

A few weeks later, the customer was running their ball mill with a resurfaced tire bearing, hopeful it would last another 30 years Portable Drill/Mill Custom designed and developed with turbine housing stud removal in mind, Atlas' portable programmable hydraulic drill has served more purposes in our field operations than plete Ball mill turnkey maintenance, inspections and repairs including Complete drive line inspections including pinion, clutch, reducer and motor alignment Complete clutch and wear pad maintenance Full inspection and regreasing of drive line bearings Trunnion bearing, seals and housing inspections Main gear and pinion inspectionBall Mill Repairs Trivett ContractingSecond, onsite repair ball mill reducer bearing seat wear case show Zaozhuang a company ball mill reducer bearing seat wear, bearing model 23144, wear one side more than ten wire, spindle speed 740 rev / min, power How to repair the ball bearing reducer bearing seat

Introduction to the maintenance of the ball millNONA

Jun 02, 2015 Demand; the ball mill to the professional bearing company ordering the amount of mold, used to repair matters, can be more economical and save a lot of trouble; the company to order professional bearing companies such as cages, roll cages, rivets and other accessories, make repair operations Simple and convenient and economicalJun 10, 2015 In the process of using ball mill, it is necessary to replace worn parts in time to avoid reducing the efficiency of ball mill or bringing damages to the other parts In addition to the routinely minor repair and maintenance, in order to detect hidden defects and abnormalities, you also need to stop grinding regularlyBall Mill Maintenance and Repair MethodxinhaiDec 24, 2019 Installation of a ball mill particular emphasis of video is how to install the trunnion bearings, scraping, etc ideal for total beginners doesnt go into mBall Mill Trunnion Bearing Installation Lafarge Ndola

Reconditioned Bearings Bearing Repair Reconditioning

Bearing Reconditioning Repair OBBCO's bearing reconditioning department can rebabbitt and recondition most any thick wall turbine, ball mill, thrust shoe or motor bearing When it comes to reconditioned bearings, nearly all crossheads and shoes are easily reworked at a huge cost and time savings when compared with buying a new partJul 03, 2016 Garden windmills bearing replacement, step by step removal and replacement of the bearingWellgo 6082RS Ball Bearings Skateboard Bearings Double Rubber SealGarden windmill troubles, bearing replacement, step by Ceramic ball mill linings will eventually wear down and need replacement Even old pebble mills with Burrstone linings can be relined with highalumina brick We tear out and dispose of the old brick, check the steel shell thickness, repair or Ceramic Ball Mill Relining and Refurbishing Paul O

BALL MILL GEARBOX PROBLEM Vibration

• Above is Peakvue spectral data from 1A ball mill when loaded (ball mill pillow block bearing, inboard, axial) • Note the vibration appearing at multiples of the outer race defect frequency (1,865 cpm) for this SKF#23240 spherical roller bearing (19 rollers) High levels of 116 g’srms were also noted as well as a high noise floorGet it as soon as Thu, Oct 21 FREE Shipping on orders over $25 shipped by Amazon Amazon's Choice for windmill bearings XiKe 4 Pack Flanged Ball Bearings 1/2" x 13/8" x 1/2" inch Be Applicable Lawn Mower, Wheelbarrows, Carts Hand Amazon: windmill bearingsball mill replacement bearings – Crusher South Africa cement ball mill maintenance trunnion bearing Service for ball mills – Polysius cement In the cement industry, ball mills are the most commonly used machines for raw Bearing Replacement Crusher Crusher Mills, Cone Crusher

Ballscrew Vertical Axis Replacement

Jog the Z axis down Remove the servo motor mount cover [1] Jog the Z axis UP until you can access the ballscrew collar nut clamping bolt [2] and loosen it Jog the Z axis UP until you can access the lower coupler collar clamping bolt We Specialize in the Repair, Rebabbitting, and New Manufacturing of: Motor Bearings, Pump Bearings, Turbine Bearings, Generator Bearings, Oil Deflectors, Guide Bearings, Guide Shoes, Trunnion / Ball Mill Bearings, Al Bearings, Exciter Bearings, Tilt Pad Bearings, Hydro Bearings, Fan Bearings, Taperland Thrust Plates, Thrust Shoes, Thin Wall Bronze Bearings, Cincinnati Babbitt Inc – The Babbit Bearing SpecialistTrunnion Bearing Y Seal For Cement Mill Slide shoe bearing replacement on a cement mill slide shoe bearing replacement on a cement mill and cement fls shoe bearing for cement mill ball mill slide shoe bearings bulk online forums hi, would anybody be able to share their experiences in relation to maintenance of cement mill slide shoe bearingsWe have a mill of Fls Shoe Bearing For Cement Mill

Repair of a Ball Mill Christof Industries

Scope of Work Dismantling of the old armouring; Replacement of the mill jacket; Check of the main bearings; Installation of the new armouring; Location: Schelklingen (Germany) Show all references See references on our world mapA ball mill is a large cylindrical tube partially filled with steel balls The ends of the steel cylinder are attached to trunnions that are supported on journal bearings As the ball mill rotates, the steel balls in the cylinder rise up on the mill's inside surface and eventually tumble down to the bottom The raw material is fed into the ball I Ball mill maintenance Fathom EngineeringJun 02, 2015 Demand; the ball mill to the professional bearing company ordering the amount of mold, used to repair matters, can be more economical and save a lot of trouble; the company to order professional bearing companies such as cages, roll cages, rivets and other accessories, make repair operations Simple and convenient and economicalIntroduction to the maintenance of the ball millNONA

Ball Mill Maintenance and Repair Methodxinhai

Jun 10, 2015 In the process of using ball mill, it is necessary to replace worn parts in time to avoid reducing the efficiency of ball mill or bringing damages to the other parts In addition to the routinely minor repair and maintenance, in order to detect hidden defects and abnormalities, you also need to stop grinding regularlyBD7057 ball mill repair special anti abrasion wearing resistant ceramic epoxy coating bearing anti wear fastening adhesive CEO : Tel:86 Fax:86 ball mill repair anti wearing ceramic epoxy resin coatings Jun 03, 2019 Ball mill drive pinion bearing wear wear online repair Enterprise 1# ball mill drive pinion bearing wear, bearing 23256CA/w33, journal 280mm, rear shoulder 33005mm, single side wear 45mm The company seeks to reach our company, and our engineers give scientific analysis and repair suggestions for this problemWhat should I do with the ball mill shaft?cement

BALL MILL MAINTENANCE COURSE The Cement Institute

The Ball Mill Maintenance course is designed to engage in the effective use of handson learning methodology as a unique combination of theory and practical work section applied to the maintenance inspection of the ball mill system This course offers an indepth understanding of the maintenance activities, providing the precise tools to achieve optimal levels of personal Cement ball mill is one of the ball mill, mining beneficiation industry one of the key grinding equipment jaw crusher bearing replacement instructions this is product template liming Crusher MachineBearings In Cement Crusher Crusher Mills, Cone Crusher Get it as soon as Thu, Oct 21 FREE Shipping on orders over $25 shipped by Amazon Amazon's Choice for windmill bearings XiKe 4 Pack Flanged Ball Bearings 1/2" x 13/8" x 1/2" inch Be Applicable Lawn Mower, Wheelbarrows, Carts Hand Amazon: windmill bearings

Prime Mining Repair and Services Prime Machine, Inc

Prime Machine Inc is in the mine service business Providing machining of the largest of the mining equipment both in our shop and on site in place machining We provide machine shop, fabrication and millwright services We have over thirty years experience servicing mining equipment and we know what it takes to make your equipment functionBall mill bearing installation and matters needing attention Ball mill main bearing bottom plate processing surface should be located in the same horizontal plane local clearance shall not be greater than 01mm, Ball Mill Bearings Clearances Crusher Mills, Cone Jan 14, 2020 There are two kinds of transmission forms of ball mill, ie center transmission and edge transmission The two kinds of transmission have their own advantages and disadvantages The central transmission adopts a highspeed planetary reducer, which is safe and reliable, with a service life of up to 10 years, low maintenance cost, but large one How to install and align the girth gear and pinion prmdrive

17 Signs of Problems with Ball Mills: Quickly Remove

Oct 28, 2021 High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% 10% 4 when the moisture is greater than 5%, the ball mill will be unable to perform the grinding operation 5 The bearing of the ball mill is overheated and the motor is overloadedHydrostatic Bearing Grinding Mills Ball Mill Bearing Design Hydrostatic Bearing Grinding Mills Components and mode of functioning: The hydrostatic sliding shoe bearing arrangement works on the principle of a plain bearing During operation there is no metallic contact between the contact surfacesBall Mill Hydrostatic Slide Shoe Bearing PDF Bearing

- specialty building materials

- Gold Ore Rock In Wisnsin

- first pacific mining

- airroc d45 d50 cm351 atlas p surface drill rigs

- general grinding media charge in mill for cemen mill

- crushing ratio mobile

- ore ball mill maintenance

- plate st 52 china hnan mill

- process equipment supply

- manganese18 chrome2 mantle bowl liner spare parts for crusher

- working principle vibration

- 2014 Hot Sale Pe250 X 400 Jaw Crusher

- nigeria iron ore crusher for hire in indonesia

- cement clinker grinding mill manufacturer

- les overt tamanrasset gold mine

- lead rougher cells for graphite mine professional

- problemas de la mandibula trituradora

- crushingstone crusher in philippines

- venta de maquinas chancadora de maiz en peru

- dolomite crusher machine in algeria

- Raymond Pendulum Mill Grinding

- spiral classifier mineral separator

- Mini Oil Palm Mill Rentec

- huron pu771 milling machine review

- Hpt Cone Crusher Flotation Machine Vsi5 Crusher

- balls for mining equipment

- ne crusher used as stone crusher

- mobile ncasseur plante À vendre

- espresso grinder grinding

- puzzolana tph crusher plant prices

- runing crusher plants in himachal for sale

- Mining Equipment Tiger

- rock crushers tons per hour

- machinery for tin mining

- mobile stone crushers price bow mill gold ore crusher

- agreegates palnt in pune

- spinning mills sales of machinery 43km multan road lahore

- Manganese Ore Dressing Equipment crusher

- limestone facts for kids

- trapezium mill vs ball mill