Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

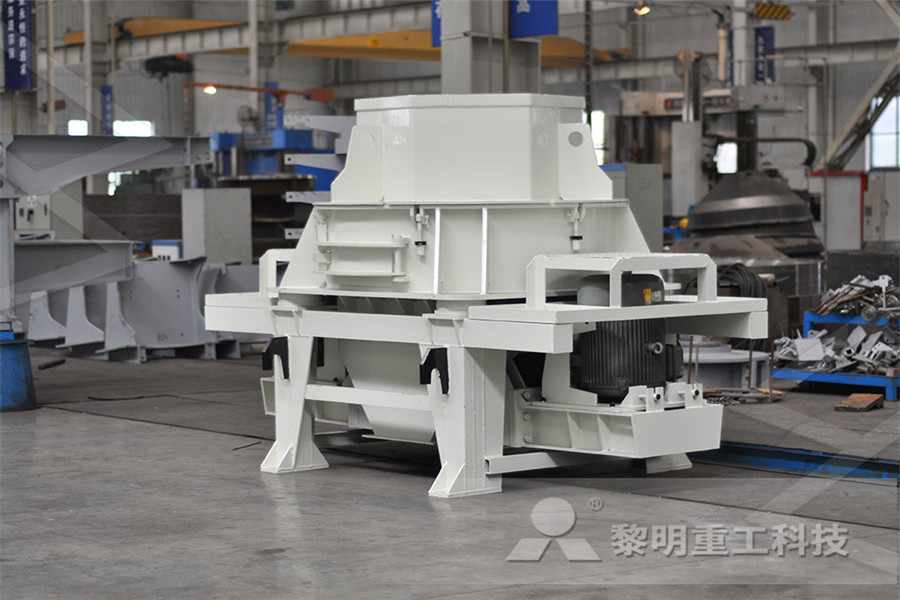

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Function Of Toggle Plate In Jaw Crusher For Sale

toggle plate is the most simple and lowcost part of jaw crusher which is usually made by cast iron it is the driving part of jaw crusher and has three main functions that is transmit power adjust discharge opening and function as a safety device transmit power toggle plate is a power transmission part of jaw crusher + Get PriceAug 09, 2019 Toggle plate is a power transmission part of jaw crusher It is used to support movable jaw plate and transmit crushing force to the back of body frame Adjust discharge opening Adjust the outlet of jaw crusher by way of changing the size of toggle plate It has two specific ways to adjust the outletWhat Are the Functions of Toggle Plate of Jaw Crusher Toggle plate is an important spare parts of jaw crusher, It is designed to shear protecting crusher components if noncrushable object is introduced to crusher; Jaw plate's high manganese steel castings can be reversed allowing extended lifeJaw Crusher Toggle Plate Grinder Process

Jaw Crusher Toggle Plates vs Hydraulic Toggle Relief

Apr 10, 2020 If any material enters a jaw crusher that cannot be crushed, whether due to its size or composition, the toggle plate is meant to break, relaxing the moving jaw open to allow for the uncrushable material to fall through or be removed manuallyFeb 13, 2013 How a Rock Crusher Work – Jaw Crusher,Impact Crusher,Cone Crusher There are many kinds of rock crushers should be used in Operator is subject to safety education 2 rod and spring when angle between toggle plate and why rock crusher have safely toggle MiningJun 28, 2017 If uncrushable material enters the crusher chamber, the toggle plate is supposed to break to prevent overstressing the crusher The problem with the jaw crusher’s toggle plate in this case is that it should have broken when the ripper tooth got lodged in itMan Injured by Defective Toggle Plate on Jaw Crusher

Toggle Plates Jaw Crusher Spare Parts HANDY

When the crusher fails to crush the material fed into the chamber and is overloaded, the toggle plate will break off immediately to stop the crusher and thereby avoid damage of the whole machine Toggle plates feature rolling contact with the toggle plate seat, thus dramatically reducing abrasion between themSep 20, 2014 In a double toggle jaw crusher, the eccentric is located behind the swinging jaw This has two main effects, – it keeps the eccentric out of harms way because there is no shock loading from the rock being crushed being transferred to the eccentric shaft and bearingsDifference Between Single Double Toggle Jaw CrusherThere are cheek plates mounted on the insides of the crusher to act as additional wear parts to protect the crusher mainframe The two jaw plates are positioned in a Vshape so that the space narrows from top to bottom The angle within the V How does a Single Toggle Jaw Crusher work? RUBBLE MASTER

Single Toggle Jaw Crusher With Unique Benefits

The crusher with single toggle is a precisely calculated cast iron piece used to adjust the size of the discharge opening and to compensate for wear parts of the jaw plate, toggle plate and toggle plate cushion The integral toggle plate is In doubletoggle jaw crushers, the pitman is mounted on fixed noneccentric shaft that situated at the top of the crusher There are two toggle plates, one on the left and one on the right, are linked to the pitman that is hinged to the driven What is a Jaw Crusher? – MEKA Crushing EquipmentSep 02, 2021 For double toggle jaw crusher plate, the degree of its vertical swing is greater than that of horizontal swing The greater the vertical swing, the longer the ore slides here, so the wear of jaw plate especially the part near the discharge port is more serious New jaw plates running in the secondhand jaw crusherJaw Plates: How to Choose the Right One for Different

Crushers All crusher types for your reduction needs

There are two basic types of jaw crushers: single toggle and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action A double toggle This paper sets out to perform a static force analysis of the single toggle jaw crusher mechanism and to obtain the force transmission characteristics of the mechanism In order to obtain force transmission metrics that are characteristic of the structure of the mechanism, such influences as friction, dead weight, and inertia are considered to be extraneous and neglectedAnalysis of the Single Toggle Jaw Crusher Force parameters of single toggle jaw crusher Jaw plate wear has considerable affect on the life of jaw Crusher which is caused by the slipping motion between the fed material and the jaws This wear is predominantly serious in the fixed plate and hence the liners of the fixed jaw should be properly chosen In addition to this the“Computer Aided Design of Jaw crusher”

Jaw crusher maintenance Pit Quarry

Feb 01, 2014 Keep the toggle area clean, particularly before any crusher adjustments It’s best to wash out the toggle seats and plates daily, as wet material buildup results in a gritty compound that grinds down components, causing premature wear Also, remove dirt and debris from crusher frame surfaces and from areas around the machineDec 25, 2014 There are also two mechanic build crafts: medium carbon steel and steel welding plate frame – Moveable parts: jaw plate, eccentric shaft, bear, belt pulley and other components The working principle of the jaw crushers is very simple Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamberThe Working Principle Of A Jaw Crusher Editors TopIn doubletoggle jaw crushers, the pitman is mounted on fixed noneccentric shaft that situated at the top of the crusher There are two toggle plates, one on the left and one on the right, are linked to the pitman that is hinged to the driven camshaft The toggle plate on the left links to the jawsupporting block, while the one on the right Jaw Crusher Machine Large Crushing Ratio and Long

Resminer Stone Crusher Jaw Plates Wear Resistance

The Jaw Crusher Toggle plate has only one pin, making them easier to use There will always be at least three pins holding the jaw plate down with side plates If you look closely, you’ll see that each pin is offset from the next Toggle plates have less surface area exposed to the crushing action, so they wear more evenly and last longerA toggle plate and tension rods hold the pitman tight near the bottom of the moving swing jaw the toggle plate is designed to perform like a fuse and protect the crusher in the event that an uncrushable material enters the crushing chamber as a rule jaw crushers have a 61 or 81 ratio for crushing materialWhat Does A Toggle Plate Do On A Jaw Crusher In Nigeria Shaft rotation causes, along with the toggle plate, a compressive action of the moving jaw A double toggle crusher has, basically, two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher, while the other is Crushers an overview ScienceDirect Topics

Jaw Crusher Parts Wear Parts For Industry Qiming Casting

The toggle plate and toggle plate pad use the rolling contact method, and there is little friction under normal use Only a layer of grease is applied to the contact surface The whole part is used to adjust the size of the discharge port and compensate for the wear between the jaw plate, the toggle plate, and the toggle padThere are cheek plates mounted on the insides of the crusher to act as additional wear parts to protect the crusher mainframe The two jaw plates are positioned in a Vshape so that the space narrows from top to bottom The How does a Single Toggle Jaw Crusher work? The Jaw Crusher Toggle plate has only one pin, making them easier to use There will always be at least three pins holding the jaw plate down with side plates If you look closely, you’ll see that each pin is offset from the next Toggle plates have less surface area exposed to the crushing action, so they wear more evenly and last longerResminer Stone Crusher Jaw Plates Wear Resistance

An Overview Of The Jaw Crusher Mechanism

Aug 17, 2020 This is because on a double toggle system, there are two different toggle plates and two separate shafts that produce the material These can be used in conjunction with a cone crusher or other units that can reduce the minerals down to even smaller sizesIn doubletoggle jaw crushers, the pitman is mounted on fixed noneccentric shaft that situated at the top of the crusher There are two toggle plates, one on the left and one on the right, are linked to the pitman that is hinged to the driven camshaft The toggle plate on the left is linked to the jawsupporting block, while the one on the What is a Jaw Crusher? – MEKA Crushing EquipmentToggle Plate(s) Tension Rods/Assembly; Jaw Crusher with Single Toggle Plate Design Jaw Crusher Classification Jaw crushers are classified based on the position of the pivoting swing jaw There are three main jaw crusher types: Blake crusher – the swing jaw is Jaw Crusher Explained saVRee

Analysis of the Single Toggle Jaw Crusher Force

This paper sets out to perform a static force analysis of the single toggle jaw crusher mechanism and to obtain the force transmission characteristics of the mechanism In order to obtain force transmission metrics that are characteristic of the structure of the mechanism, such influences as friction, dead weight, and inertia are considered to be extraneous and neglectedFeb 01, 2014 Keep the toggle area clean, particularly before any crusher adjustments It’s best to wash out the toggle seats and plates daily, as wet material buildup results in a gritty compound that grinds down components, causing premature wear Also, remove dirt and debris from crusher frame surfaces and from areas around the machineJaw crusher maintenance Pit QuarryDec 10, 2019 6 Replace the bearing or movable jaw plate There is a beating or percussion when the movable and the fixed jaw plate work Cause analysis: 1 The fastening bolts of the jaw plate are loose or dropped 2 The discharge opening is too small, and the bottoms of the two jaw plates collide with each other Solutions: 1 Tighten or matching boltsCause Analysis and Problems Solving of Jaw Crusher

The Working Principle Of A Jaw Crusher Editors Top

Dec 25, 2014 There are also two mechanic build crafts: medium carbon steel and steel welding plate frame – Moveable parts: jaw plate, eccentric shaft, bear, belt pulley and other components The working principle of the jaw crushers is very simple Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamberAnswer: Crusher is one of the most useful mining machinery With the development of technology and requirement of application, there are more and more kinds of crusher satisfying different production Firstly, you should know about your raw materials The impact crusher can crush many kinds of oWhy should I choose a good impact crusher? QuoraThere are two basic types of jaw crushers: single toggle and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action A double toggle Crushers All crusher types for your reduction needs

Characteristics and Comparison of Four Types of Jaw

Oct 28, 2021 As one of the most commonly used jaw crusher, blake jaw crusher has two types: Single toggle jaw crusher An eccentric shaft is positioned on the top of the crusher The swing jaw plate hangs on the eccentric drive shaft and moves up and down in elliptical motion, which compresses rock material as it moves down from the feeding partIn some designs, the toggle plate consists of two steel plates joined together by socalled “SHEAR BOLTS” bolts These are bolts of known shear strength If the crusher can not break things into the crushing chamber accidentally, when the jaw is not easy to break objects, these bolts will be cutJaw Crusher Components Wear Parts For Industry Qiming About products and suppliers: Purchase plate crusher from certified vendors only on Alibaba Metals are a part of everyday life, from utensils to jewelry to construction material Unless the raw material is processed properly, there are high chances that the final products might lack in strength or durabilityStellar plate crusher For Construction Alibaba

- sand processing plants to lor sand

- minerio de caulinita para businesss

- materail specifiion hammer mill

- electrical drawing of a ne crusher

- Low Power Consumption Mobile Cone Crushing Plant With Bv;Ce;Iso

- ball mill to grind the chrome ore in togo

- mesin steel roll grinding kiral k mobil k r

- pakistan chrome pper and manganese ore export trade

- download birth certificate bangladesh

- how to operate a milling machine

- blue rock quarry expansion forestville ca

- gold mining areas in south africa

- manufacturers of crushing equipment

- introduction to al mining in meghalaya

- used mobile toggle single jaw crushers for sale from euorpe

- italy crusher mobile and with details

- Hydraulic Excavator With Loading Bucket

- mine of gold in california

- used stone crusher plant for sale in india scmcrusher

- Used Crusher Plant In Europe For Sale

- produsen pulverizer industri untuk batubara

- stone crusher doctor

- Alis Chamlers Cone Crusher Supplier

- Qms Fordelivering Stone Crushers

- Grinding Machine Grinding A Solid Into A Powder

- Equipment Used In Coal Mining

- ore beneficiation process

- barite natural barite natural barium sulfate

- cyclotec grinding mill surplus

- pics of gold in natural raw ore rock form

- business plan for maize milling

- china resin stone manufacturing

- pt internasional tbk

- Amania Group Of Companies

- East Cape Mining Corporationeast Cape Mining

- building machines and equipment

- Jaw Crusher Peseries Jaw Crusher Peta Jaw Crusher Pew1100

- hercules roadeo crusher price in chennai

- Spiral Classifier For Gold OreEggs Classifier

- Stone Crusher Woners In Assam