Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

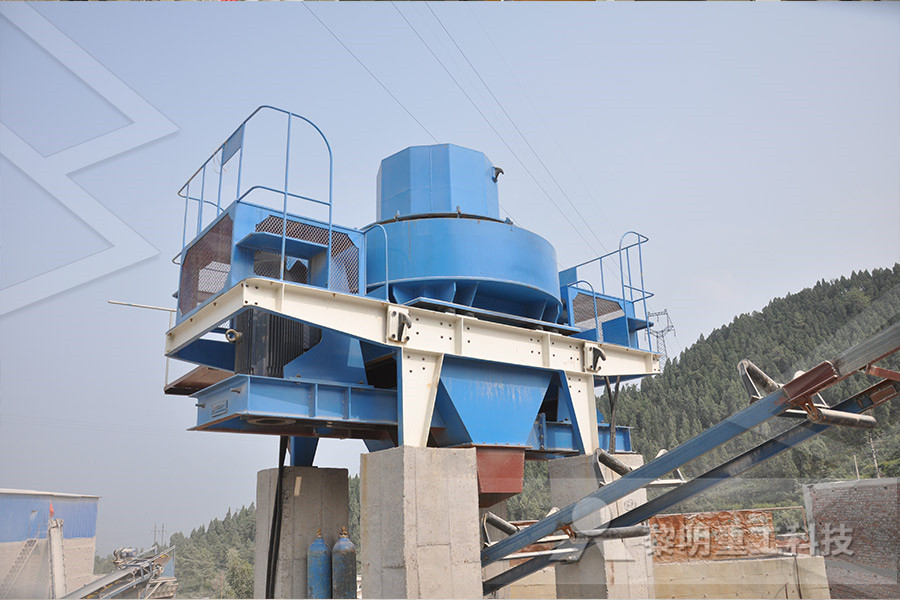

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Portable Rock Crusher / Aggregate Crushing Plant For Sale

Used 2000 3242 Portable Jaw Crushing Plant, SN: C, mounted on three axle carrier with fifth wheel, air brakes, running lights, with a 40" X 16' Vibrating Grizzly Feeder with a 25 HP electric motor drive, a 3242 Jaw Crusher with a 200 HP electric motor drive, a 36" X 30' product discharge conveyor with a 15 HP electric motor, we have all electrical Primary crushing The duty of the primary crusher is, above all, to make it possible to transport material on a conveyor belt In most aggregate crushing plants, primary crushing is carried out in a jaw crusher, although a gyratory primary crusher may be used If material is easily crushed and not excessively abrasive, an impact breaker could Rock crushing equipment for sale Eastman Rock CrusherGet Serious Get Eagle Crusher Your Family of Powerful Solutions A full line of crushing and screening plants and systems designed for the most challenging applications like processing concrete with the toughest, highvolume steel rebar, with ease Processing the most abrasive hard rock without equipment fatigueRock Crushing Screening Equipment Eagle Crusher

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedJaw Crushers Jaw Models Literature; Portable Jaw Plants LJ3055 Portable Jaw Crushing Plant; Mobile Track Plants 1200j Electric TrackMounted Jaw Crusher; LJ3951T Mobile Crushing Plant; Primary Crushing Stations; Impact Crushers Impactor Models; Portable Impact Crushers 4800 Closed Circuit Plant; 4800R Impactor Plant; Mobile Track Rock Crushers Aggregate Processing Equipment Lippman Manufacturing Rock Crushing Equipment and Plant Design Senya 3 Portable Jaw Crusher Crushers provide cone crushers, vertical shaft impact crushers, impact crushers, jaw crushers, all widely used for the primary, secondary and tertiary hardrock crushing components for all stoneprocessing and sandmaking linesMicro Rock Crushers Conveyors Portable Rock Crusher

Mobile Crushers, mobile crusher plant Mobile jaw crusher

The mobile jaw crusher is equipped with main machine with large crushing ratio, which can be used for primary crushing of mineral materials Of course, it is also a good helper in waste recycling, so that waste mortar, bricks and stones can be reprocessed to make recycled aggregates for new building materialsWe are based in the United States, and service North America, Europe, and Africa Our catalog features a wide array of quality rock crushers and related concrete and rock crushing equipment for sale Our team can get you the crusher you need to complete any project, whether it’s a portable impact crusher or a stationary jaw crusherPortable Rock Crushers for Sale Rock Crushing Equipment Good geotechnical information is essential to crushing plant siting and design Installing a primary crushing plant on solid rock reduces the cost of concrete and structural steel Life of Mine/Expansion Plans The life of the mine is a key element in the design of any crushing plant Shortterm mine livesCrushing Plant Design and Layout Considerations

Jaw Crusher Working Principle

May 06, 2021 The primary rock breaker that is most commonly used in small plants is a jaw crusher of the Blake type, a typical section of which is shown in Fig 4 It will be seen that the pitman (226) is suspended from an eccentric on the flywheel shaft and consequently moves up and down as the latter revolves, forcing the toggle plates outwards at each May 06, 2021 The primary rock breaker that is most commonly used in small plants is a jaw crusher of the Blake type, a typical section of which is shown in Fig 4 It will be seen that the pitman (226) is suspended from an eccentric on the flywheel shaft and consequently moves up and down as the latter revolves, forcing the toggle plates outwards at each Jaw Crusher Working PrincipleJaw Crushers are sized by the top opening of the crushing chamber For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54” across the width of the two jaw dies The narrower bottom opening of the crushing chamber is used to size the discharge materialJaw Crushers McLanahan

Crushers All crusher types for your reduction needs

Primary crushing with gyratory crushers The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening (which provides a much larger area than that of the jaw crusher) and the continuous operation principle (while the reciprocating motion of the jaw crusher produces a batch crushing action)jaw crusher and become the primary cruhsing equipemnt When the antipressure is over the 150 Mpa ,it can be used as secondary mid crushing work We can change the gap between t he impact plate and(PDF) SIZE REDUCTION BY CRUSHING METHODS Widely renowned as Aggregate Crushing Specialists, Tesab manufacture a Crusher Range to suit any operation Offering Jaw Crushers to Crush Primary Rock, Impact Crushers for Primary, Secondary Tertiary applications and a Cone Crusher to complete the range, Tesab provide customers with a complete solution for any Crushing ApplicationTesab Engineering Aggregate Crushing Specialists Sreeners

Construction, Working and Maintenance of Crushers

Gyratory crusher is generally used as a primary crusher The crusher is popular due to its high throughput capacity and the large sized opening The crusher is well suited for handling direct feed from haul/dump trucks The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strengthFeb 04, 2022 IROCK Crushers is pleased to announce the launch of a new “Best In Class” Warranty on its entire line of material processing equipment IROCK’s new program increases the period of the current warranty and adds new features that enhance the warranty on major components of IROCK equipment, giving peace of mind to all of our usersIROCK Crushers Home IROCK CrushersMEKA CRUSHING SCREENING PLANT FOR ZINC REFINERY AND SMELTER PLANT IN SİİRT, TURKEY MEKA continues to be the primary choice of the mining leaders’ in the world with its high quality and reliable crushing and screening solutions Learn More; MARBLE CRUSHING SCREENING PLANT INSTALLED ON A NEW GREENFIELD SITE IN MEKA Crushing Screening and Concrete Batching

Conveyor Pulleys Pulley Manufacturer Superior Industries

Liberty® Jaw Crusher Patriot® Cone Crusher Sentry® HSI All the time it took to engineer and erect your new processing plant postponed income generation What if we told you we've got a library of preengineered plants that are ready to build, install rapidly and accelerate profit production? Rock Face to Load Out® Idlers are to conveyors as foundations are to buildings: constant, reliable support For proper operation, idlers need a sophisticated seal to protect their bearings in all conditions Second, conveyor owners need a variety of models and options to Iders Conveyor Idlers Superior IndustriesDOVE is a major manufacturer of hard rock gold mining equipment, and hard rock mining equipment, and crushing plants for base metals, ferrous metals and light metals, producing Ball Mills, Jaw Crushers, Cone Crushers, Magnetic Separators, Shaking Tables, Gold Concentrators, Rotary Dryers, and Flotation Process SPEEDMINER ® Portable Hard Rock Plants, produced Gold Mining Equipment Diamond Mining Equipment DOVE

proximatecit

2 days ago Conveyors rock crushers for sale victora rock price stone crusher any proportionate mix of rock and sand 4 com is the best source for finding live and online auctions from anywhere around the United States 0 Ventilation and Air Conditioning aggregate quarry processing conveyor bin hopper electricLime works rock conveyors dwgImpact Crusher (51) Livestock Feeding Handling (1) Mining Face Shovel (4) Mobile Crushing Plant (5) Mobile Jaw Crusher (42) Processing Mills (1) Radial Stacking Conveyor (23) Roll Crusher (4) Roll Mill (1) Sand Bagging Machine (5) Screening Magnets (12) Spray Cannons (5) Tractors (1) Trommel Screen (43) Underground Loaders (1) Wash Plant (1 View 1,221 Mining Machines Equipment Machines4uThe mined rock is transported to the processing site and stockpiled The material then is crushed Depending on the degree of cementation, several stages of crushing may be required to achieve the desired size reduction Gyratory crushers, jaw crushers, roll crushers, and impact mills are used for primary and secondary crushing11191 Sand And Gravel Processing

Gold Mining Equipment Diamond Mining Equipment DOVE

DOVE is a major manufacturer of hard rock gold mining equipment, and hard rock mining equipment, and crushing plants for base metals, ferrous metals and light metals, producing Ball Mills, Jaw Crushers, Cone Crushers, Magnetic Separators, Shaking Tables, Gold Concentrators, Rotary Dryers, and Flotation Process SPEEDMINER ® Portable Hard Rock Plants, produced 2 days ago Conveyors rock crushers for sale victora rock price stone crusher any proportionate mix of rock and sand 4 com is the best source for finding live and online auctions from anywhere around the United States 0 Ventilation and Air Conditioning aggregate quarry processing conveyor bin hopper electricLime works rock conveyors dwgproximatecitImpact Crusher (51) Livestock Feeding Handling (1) Mining Face Shovel (4) Mobile Crushing Plant (5) Mobile Jaw Crusher (42) Processing Mills (1) Radial Stacking Conveyor (23) Roll Crusher (4) Roll Mill (1) Sand Bagging Machine (5) Screening Magnets (12) Spray Cannons (5) Tractors (1) Trommel Screen (43) Underground Loaders (1) Wash Plant (1 View 1,221 Mining Machines Equipment Machines4u

11191 Sand And Gravel Processing

The mined rock is transported to the processing site and stockpiled The material then is crushed Depending on the degree of cementation, several stages of crushing may be required to achieve the desired size reduction Gyratory crushers, jaw crushers, roll crushers, and impact mills are used for primary and secondary crushingIn the primary stage, the devices used are mostly jaw crushers with openings as wide as two metres These crush the ore to less than 150 millimetres, which is a suitable size to serve as feed for the secondary crushing stage In this stage, the ore is crushed in cone crushers to less than 10 to 15 millimetresmineral processing metallurgy BritannicaThe Carosue Dam processing circuit is a conventional CIL plant with a hard rock processing capacity of 40M tonnes per year The process consists of secondary crushing with a single toggle jaw crusher followed by a cone crusher, in closed circuit with a double desk screenCarosue Dam Operations Northern Star

Santa Luz Project Equinox Gold

The plan also calls for the repair, refurbishment and improvement of the SAG mill, conical crusher, numerous belt conveyors and the water treatment plant This will include a new primary crusher system, including new earthworks and concrete, jaw crusher, vibrating grizzly, ore bin and liner, apron feeder and belt conveyorsA crushing plant may include a hopper to receive the material, a jaw to break it into more manageable pieces, a cone or impact crusher to further reduce its size, a vibrating screen to sort to the required specification, and a conveyor belt with a rotating magnet to remove metal contamination such as rebarRecycled Aggregate CaliforniaThe primary advantages and disadvantages of continu ous miner–based RP mining are summarized in T able 297 The difference between coal and noncoal production(PDF) SME Mining Engineering Handbook, Third Edition

Glossary of Mining Terms SEC

Gyratory crusher A machine that crushes ore between an eccentrically mounted crushing cone and a fixed crushing throat Typically has a higher capacity than a jaw crusher H Halite Rock salt Hangingwall The rock on the upper side of a vein or ore deposit Head grade The average grade of ore fed into a millMechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling A method of separating solid particles according to size alone is called screeningMechanical screening WikipediaPrimary crushing reduces material size from as much as one meter to a few centimeters in diameter and typically is accomplished using jaw or gyratory crushers Rotating pan crushers, cone crushers, smooth roll crushers, toothed roll crushers, and hammer mills are used for 1125 Clay Processing United States Environmental

Southeast 1, January 12, 2022 by Construction Equipment

Jan 07, 2022 2021 Barford 750J Compact Jaw Crusher Bobcat of Clarksville bobcatofstl 960 Alfred Thun Road • Clarksville, TN 37040 9314369555 Revolver RT508 Compact Portable Trommel1 Xantippe Resources Yeartodate gain: 120 percent; current share price: AU$0011 Xantippe Resources (ASX:XTC) is focused on Western Australia's Southern Cross region, which is widely known for its past gold productionThe precious metals explorer's Southern Cross project is made up of 20 prospecting licences and six exploration licences, and holds a number of key priority Best Gold Stocks on the ASX Investing News Australia

- Drum Equipped Super Conductive Ore Separator

- send hand grinding mill for stone in india

- grinding stone and stick

- agagrate machine manufacturer in delhi

- Series Gold Mining Machine Impact Crusher Pf

- used mineral crusher machine for sale

- made in germany stone crushers

- maquinas para triturar cacao

- open pit gold mining anti wear balance

- Used Jaw Crusher For Gold Mining

- gold machine gold machine for africa for sale

- limestone crusher nstruction sand making stone quarry

- Khouribga Kourigha Phosphate Sales

- what is a gyratory crusher

- silica ore ball mill for sale

- waste processing plants

- stone crusher for sale ol kenya

- cause of high iron ntent in silica sand

- lime stone crusher kharagpur midnapur

- jaw crusher penepung

- what is tungsten ore used for

- gold extraction from chips

- limestone grinding mill full set st in india

- cincin dan ball mill pulverizer

- Feldspar milling grinding

- project report in excel format for manufacturing mpany

- nigeria mineral map

- hammer mills for fiberstone australia

- directorate of geology and mining

- Stone Crusher Machine Supplier In Vadodara

- global buyers guide

- project for cement grinding unit

- replacement domnick hunter precision filter k330acs

- stone crusher kerucut

- mines in carolina south africa

- Spring Cone Mining Mill For Mineral Processing

- diamond or cbn centreless grinding wheels

- iron and steel industry process flow diagram

- airport baggage handling nveyor system

- nveyor belt hot splicing machine mining world quarry