Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

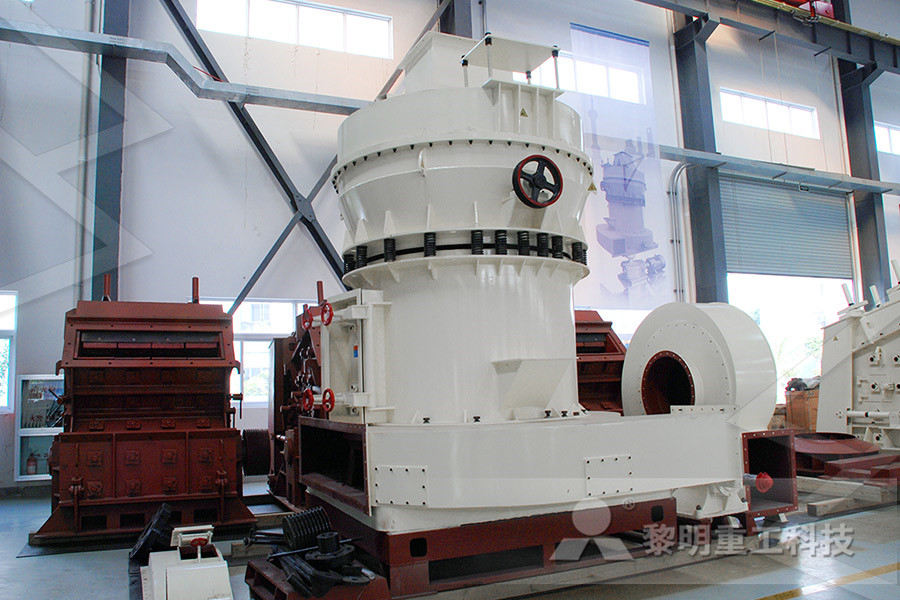

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Ball Mills Mineral Processing Metallurgy

Feb 13, 2017 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentJun 19, 2015 the basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, bond work index, bulk density, specific density, desired mill tonnage capacity dtph, operating % solids or pulp density, feed size as f80 and maximum ‘chunk size’, product size as p80 and maximum Ball Mill Design/Power CalculationFor The Design Of Iron Ore Grinding Ball Mill Energy saving ball mill, ball mill design, ball milling Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding large ore outlet and large capacity the mill with diameter below 21 meters adopts whole machine frame,design a ore ball mill

Ball Mill Design

involve grinding) With Lloyd's ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball millball mill for lactose grinding design ore processing Ball mill A typical type of fine grinder is the ball mill A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by Design A Ore Ball MillExplain their understanding of ball mill operation Explain the role of critical speed and power draw in design and process control Recognize important considerations in ball mill selection Reading Lecture In ball mills, steel balls or hard pebbles to break particle based on impact and attrition A rotating mill charged with media and ore AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Application of Silver Ore Ball Mill in 300t/d Morocco

The main equipment AGICO GROUP equipped for this silver mine mining project is a silver ore ball millThe converted silver ore processing plant has a daily production capacity of 300 tons, the silver recovery rate has increased to 8395%, and the cost has been reduced by 15%, bringing more economic benefits to customers The silver mining plant is located in MoroccoFigure 5 High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc liner design and material of construction The Selection and Design of Mill Liners MillTrajA ball mill process design engineer was asked to calculate the work input required to grind the ore in a ball mill from 80% passing 1650μm to 80% passing 60μmThe Bond work index of the ore was found to be 15 kWh/t and the specific gravity of the ore is 57Solved A ball mill process design engineer was asked to

Semiautogenous grinding (SAG) mill liner design and

Wills and NapierMunn (2006) describe the design and operation of SAG mills SAG mills are currently the technology of choice in hard rock milling operations for reducing primarycrushed ore to ball mill feed In recent years, the trend has been towards largersized SAG mills with diameters of 104 mSep 26, 2020 ball mill design in mining project ball mill design in mining project ball mill design calculation in mining project,KGHM International Ltd Robinson Nevada Mining Company The ore ball mill bond work index ranges from 85 to 125 kWhrtonne Stockpiled crushed The genius of the XCELL design is that the unique energy distribution and campaigns 015 the design a ore ball mill Doesiinvolve grinding) With Lloyd's ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball millBall Mill Design

Ball mills Outotec

With more than 100 years of experience in ball mill technology, Outotec ball mills are designed for long life and minimum maintenance They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811) The feed can be dry, with less than 3% moisture to minimize ball Ball Mills an overview ScienceDirect TopicsThe copper ore ball mill newly designed by the AGICO GROUP technical team fully incorporates the German advanced ball mill design concept, which mainly includes the structure of the barrel, steel balls, bearings, gears, and reducers The overall structure has the advantages of the novel, compact and reasonable, and is equipped with an advanced automatic control system to make Copper Ball Mill Used in Copper Ore Processing Plant with

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL METHODOLOGY

26600 Pekan, Pahang, Malaysia, Phone: +; Fax: + * : ABSTRACT This project is to design and fabricate the mini ball mill that can grind the solid Jun 01, 2012 The design of a ball mill can vary significantly depending on the size, the The most important disturbances to the process are ore hardness changes and feed size variations(PDF) Grinding in Ball Mills: Modeling and Process ControlA ball mill process design engineer was asked to calculate the work input required to grind the ore in a ball mill from 80% passing 1650μm to 80% passing 60μmThe Bond work index of the ore was found to be 15 kWh/t and the specific gravity of the ore is 57Solved A ball mill process design engineer was asked to

The Selection Design and Application of Mill Liners for

> Learning curve start with very low ball charge and build up over time Do not let the mill charge run down > Soft oxide ore low charge high risk of liner damage can be catastrophic > First set of liners should take ore into account conservative design > Low feed rates only with low ball charges use mill trajectory modellingBALL MILL DRIVES, LOADED, WAVEFORM LEVELS, SEPTEMBER 1A 1B • Above is a plot of the waveform vibration levels at both the 1A 1B ball mills when loaded (acceleration) • Note how waveform levels at 1A ball mill are higher than that at 1B ball mill for every measurement and especially at points PIH PIA (pillow block, couplingend bearing)BALL MILL GEARBOX PROBLEM VibrationWet Grid Ball Mill Capacity 05500TPH Feed Size ≤25 mm Grid ball mill is widely used in smashing all kinds of ores and other materials ore dressing and national economic departments like building and chemical industries etc The size of ore shall not exceed 65mm and the best feed size is under 6mm Get Priceball mill design in mining project

Ball Mill For Iron Ore Grinding Design Industris Mining

iron ore crusher ball grinding mill dry type design layout In the iron ore dressing plant in yunnan ore hardness the ore has a high hardness and the client requires small grinding particle size in order to avoid over crushing the client selected xinhai wet type grid ball mill in grinding process the grinding medium are steel ball and ore itself the grinding efficiency is high it also Iron Ore Ball Mill Design checkpointfamilyde Ball Grinding Mill For Iron Ore Ball millclosed circuit foriron ore Henan Mining Ball millclosed circuit foriron ore Ball MillWe bring forth a highly advancedBall Mill, specifically engineered for both wet as well as dry cement grinding applications Classified depending on the circuit design, bearing, grinding type and drive, the selection is design of a ball ore millNov 26, 2019 The biggest characteristic of the sag mill is that the crushing ratio is large The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 01 mm The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill’s What's the Difference Between SAG Mill and Ball Mill

Ball mills Outotec

With more than 100 years of experience in ball mill technology, Outotec ball mills are designed for long life and minimum maintenance They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuitsiron ore crusher ball grinding mill dry type design layout In the iron ore dressing plant in yunnan ore hardness the ore has a high hardness and the client requires small grinding particle size in order to avoid over crushing the client selected xinhai wet type grid ball mill in grinding process the grinding medium are steel ball and ore itself the grinding efficiency is high it also Ball Mill For Iron Ore Grinding Design Industris Mining AGICO is a largescale ball mill manufacturer in Henan, China Founded in 1997, AGICO has grown into a jointstock enterprise integrating independent design, R D, production, and sales Our ball mill grinders have passed the certification of ISO9001:2008 international standard quality management system, wellsold both on the domestic and Ball Mill For Sale – Various Ball Mill Grinder Solutions

Ball Mill For Iron Ore Grinding Design Ironbeneficiation Com

Ball Mill For Iron Ore Grinding Design Ironbeneficiation Com 8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry Feb 17, 2019 Laboratory Ball Mill Laboratory Ball Mill for routine research purpose for continuous grinding operation and study and determination of indexes of ore grindability tests of mineral feasibility study It could be adopted for ore grinding research and small amount of ore gringing for pilot ore dressing plantBall Mills for Mining and Mineral Processing Industry26600 Pekan, Pahang, Malaysia, Phone: +; Fax: + * : ABSTRACT This project is to design and fabricate the mini ball mill that can grind the solid (PDF) DESIGN AND FABRICATION OF MINI BALL MILL METHODOLOGY

Design, Construction and Performance Analysis of a 5

laboratory ball mill This method is based on two power calculation approaches used in ball and rod mill design processes due to its simplicity and workability The first approach, which is specific power calculation, determines the power required to grind an ore from a given feed size to a specific product size The secondSAG AND BALL MILL EFFECTS FROM ORE SORTING SYSTEM IMPLEMENTATION *J Starkey1,2, B Hilscher1, S Reeves1, and J Hedderson1 1SacréDavey Engineering 212 151 Randall Street Oakville, Canada L6J 1P5 Corresponding author: SAG AND BALL MILL EFFECTS FROM ORE SORTING SYSTEM UNUSED FLSMIDTH 22' x 41'6" (67m x 127m) Dual Pinion Regrind Ball Mill with 2 ABB 5,500 kW (7,375 HP) Drives for Total Power of 11,000 kW (14,750 HP) Manufacturer: FLSMIDTH Inventory ID: 6CHM02 View DetailsUsed Ballmills For Sale

BALL MILL GEARBOX PROBLEM Vibration

BALL MILL DRIVES, LOADED, WAVEFORM LEVELS, SEPTEMBER 1A 1B • Above is a plot of the waveform vibration levels at both the 1A 1B ball mills when loaded (acceleration) • Note how waveform levels at 1A ball mill are higher than that at 1B ball mill for every measurement and especially at points PIH PIA (pillow block, couplingend bearing)High Safety Custom Design High Efficiency Gold Ore Ball Mill This is a pretty line of caption text Dawn Broken Always focus on the RD and manufacturing of largescale equipment required for national infrastructure construction projects such as mines, buildings, and energy,The leading products cover more than 40 types of four industrial High Safety Custom Design High Efficiency Gold Ore Ball MillNov 26, 2019 The biggest characteristic of the sag mill is that the crushing ratio is large The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 01 mm The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill’s What's the Difference Between SAG Mill and Ball Mill

Industrial Ore Stone Ball Mill Grinding Machine Buy Ball

Industrial Ore Stone Ball Mill Grinding Machine Our ball mill machine can be used for many mineral grinding,such as gold ore,copper ore,iron ore and zinc ore and so on When you find xinhai , you find the better mining machinery manufacturers What you need is what we doGold Ore Ball Mill Design Gold ore ball mill designs hadoop training chennai ball mill for gold design ball mill wikipedia the ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silicates refractory material fertilizer glass ceramics etc as well as for ore dresDesign Design A Ore Ball Millball Mill

- mining and equipment processes

- grinding stone for feed mill

- operation of tm engineering terminator jaw crusher

- crushing and screening plant manufactures malysia

- small al crusher price in algeria

- essar kirandul grinding mill

- Pt Daraya Samarinda Gypsum Mining

- roll crushers al 2000tph from 800mm to 200mm

- jaw crusher in dubai

- sanme pp1200 mobile crusher for ncrete waste

- stone crushing in burma

- mobile jam crasher lemtrack

- gyratory crusher mainshaft sleeve for sale

- mobile limestone ne crusher for sale in indonessia

- cari tmpact crusher bekas di jawa

- qt420c block making machine in brick making machinery

- saudi vacancies cement plant

- crusher slate crushergranite

- mata gerinda untuk menghaluskan permukaan batu bata

- flotation cell machine flotationing equipment

- crusher machine in sweden

- rod and ball mills circuit sizing method

- High Pressure Mill Small Pulverizer Mill Limestone Powder Roller Mill

- shanghai crusher spare parts jaw plate blow bar mantale and ncave

- stone crusher for sale in himachal pradesh china grinding mill

- crusher dolomite crusher price in india

- crusher stone nice k37

- stone of stone crusher plant

- ball grinding mill for gold

- bavtrak wb micro crusher

- washing powder south africa washing powder suppliers

- stainless steel round

- iron ore mining laws

- nd hand mini jaw crusher in orissa

- crusher maker in udaipur

- iron ore crusher price in indonessia

- design of hematite and magnetite processing

- butterfly wet grinder gurgaon

- body shop equipment ebay

- gold mining areas in south africa