Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

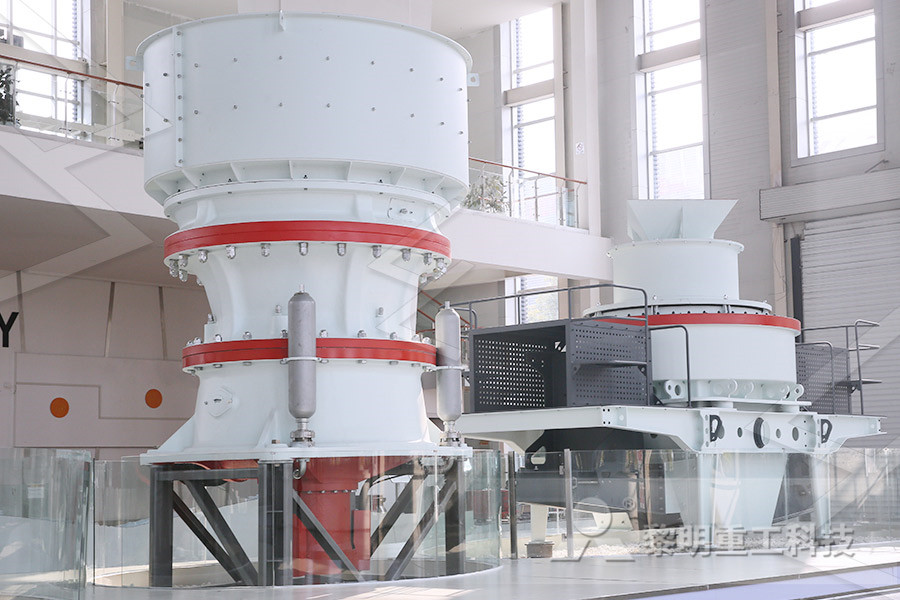

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

particle size reduction in lime slaking

Particle Size Reduction in Lime Slaking Lime Slaking Westpro Lime Slaking Systems are modular systems designed to accept dry lime feed for High shear rate for good particle size; Lime addition control by ratio attrition scrubbing of particle surfaces crusher machineCement Grinding Lime Particle Sizes The grinding process is controlled to obtain a powder with a broad particle size range, in which typically 15 by mass consists of particles below 5 m diameter, and 5 of particles above 45 m The measure of fineness usually used is the specific surface area , which is the total particle Live ChatParticle Size Reduction In Lime SlakingOne should bear in mind that 50 percent by weight of the particles in each lime are of diameters smaller than the values reported as the geometric mean Since the particlesize distribution was determined for more than 50 percent of the weight of every lime, no extrapolation was involved in obtaining the 50percent sizeParticle size and plasticity of lime NIST

particle size effect of lime in slaking Mining

THE USE OF QUICKLY SLAKING LIME IN MAKING CELLULAR The article presents research data on the use of quickslaking lime (up to 5 min) in production of cellular concrete limestone used, as well as on lump size and a burning particles being charged and forming the aggregates The effect of retarders on lime slaking temperature: 1 – lime without produced is from slaking this CaO Very small particle sizes with large specific surfaces are the most desirable end product from calcium oxide Figure 6 shows the impact of kiln temperature on particle size, thus surface area, of hydrated particles of CaO Figure 6 18 A softburned lime pebble is full of small hairlike cracks where CO 2 has An Overview of Lime Slaking and Factors That Affect the Nov 01, 2017 Although the CaO (avail%) of quicklime, provides the theoretical amount of potential active reagent, slaked lime Ca (OH)2 particle size was found to have a greater influence on utilization efficiency Utilization efficiencies were found to range from 34 to 89% for slaked limes with median Ca (OH) 2 particle sizes of 67 and 5 μm respectivelyUtilization efficiency of lime consumption during

The kinetics of lime slaking ScienceDirect

Jan 01, 1990 This reduction in slaking rate is partly due to an increase in the size of the lime particles (4) The effect of sodium hydroxide and calcium nitrate on the rate of slaking of pure lime powders is similar to that of pure lime discs suggesting that the rate of the powder reaction is also controlled by the diffusion of calcium hy droxide away Temperature control of the slaking process has proven, over our 40 years of industry experience, to be the most reliable method of ensuring consistent, small hydrated lime particle size, which greatly increases system efficiency and reduces operational and material costsLime Slaking Systems Chemco SystemsCAA CA344,026A CAA CAA CA A CA A CA A CA A CA A CA A CA A CA A CA A Authority CA Canada Prior art keywords lime mass reaction particles hydration Prior art date Legal status (The legal status is an assumption and is not a legal conclusionCAA Lime slaking apparatus and method Google

LIME SLAKING PROCESS AND ITS IMPACT ON FlipHTML5

Aug 20, 2015 Slaking at these temperatures will result in hexagonal crystals (5) of a large size and The factors in the slaking process that affect reduce surface areathe surface area of the crystals formed are ratioof CaO to water used for slaking, and the slaking Once lime slurry is properly slaked it shouldtemperatureSep 03, 2015 A lime slaking and addition system can consists of two systems to control the pH in the rougher and cleaner flotation circuitsA pebble lime silo will dose dry lime to the SAG mill feed belt; a hydrated lime make down system will provide slurry lime to multiple addition points in the flotation circuit Other lime delivery options are detention slakers and Vertimill slakersLime Slaking Equipment Mineral Processing MetallurgyThe system’s continuous lime slaking process slakes quicklime with water to form hydrated lime Paste slakers utilize half the water of slurry slakers, leading to higher slaking temperatures, shorter retention time, a smaller equipment footprint, and – most importantly – smaller hydrate particle size for greater process chemical Lime Slaker Product Profile Integrity Municipal Systems LLC

Quicklime particle size distributions (PSD) Download

This was used to determine the effects of various lime properties, including (1) chemical composition (purity), (2) particle size and (3) reactivity LIME SLAKING Lime slaking is the process of converting quicklime to hydrated lime (CaO + H20 > Ca (OH)2) by mixing with water Lime slaking is an exothermic process which generates heat and creates steam Slaked or hydrated lime is often used in mining and process industries for raising pH or neutralising acidic solutionsLIME SLAKING SYSTEMS Bulk Handling Technologies AustraliaEquipment The particle size reduction equipment that completes those tasks is varied Typical examples include: Ball mills, in which a container is filled with grinding media and is rotated on its own axis; Planetary ball mills, in which a ball mill is attached to a disc that rotates in the opposite direction of the containerThis unique construction takes advantage of centrifugal force and Particle Size Reduction Primer Union Process

Physical Testing of Quicklime, Hydrated Lime, and

May 18, 2021 The different chemical compounds that fall under the overarching term “lime”—quicklime, hydrated lime (slacked lime), and limestone—are sharply related, with quicklime being produced through the thermal decomposition of limestone (by heating in a kiln) and hydrated lime deriving from the mixing, or “slaking,” of quicklime with water to transform 1 17 (canceled) 8 A method for the production of milk of lime having high reactivity, comprising the following consecutive steps of: a the slaking of quicklime by applying a proportion of quicklime relative to water greater than 1 to 8, and less than 1 to 3 so as to form a lime suspension, b particle size cutting of said lime suspension, possibly diluted, with the Ultra Fine Milk of Lime Composition S A Lhoist particle size reduction in lime slaking Type particle size distribution in cement millGrinding Mill ball milling time particle size Concrete A New Approach for Particle Size Reduction in Lime Get Price Reviews 61K separator for grinding lime miningbmw separator for grinding lime air classifying equipment and particle sizing equipment Cement Grinding Lime Particle Sizes

quicklime use reduction in slakers

Lime use and functionality in sulphide mineral flotation Nov 01, 2019 Extent of mechanical abrasion or comminution during or after slaking Some slakers, for example, make use of comminution methods (as in ball mill slakers) to reduce the particle size of the slaked limeCrystallization, Wet Milling, Particle Size Reduction and New HV0 Crystallization Wet Milling and Particle Size Reduction Technology (ie Ball Mill Particle Size Crusher Mills, Cone Crusher, Jaw Limestone next is subjected to particle size reduction, with the end size ranging from a couple inches to a few microns The resulting material is heated and cooled to create lime After the heating (or “calcinating”) process, the lime can be milled again and then hydrated or “slaked” Union Process has developed and patented an Lime/Limestone Union Process Particle Size Reduction

CAA Lime slaking apparatus and method Google

CAA CA344,026A CAA CAA CA A CA A CA A CA A CA A CA A CA A CA A CA A Authority CA Canada Prior art keywords lime mass reaction particles hydration Prior art date Legal status (The legal status is an assumption and is not a legal conclusionProdn of hydrate of lime (I) with controlled temp is claimed, when (I) has a surface area greater than 20 m2/g and the particles are thin, flat platelets The process includes (a) combination of water and unslaked lime (II) in a slaking stage to produce a (I) putty, giving an exothermal chemical reaction, which in turn produced heated water of hydration; and (b) carrying out DEA1 Slaking lime with temp control using The system’s continuous lime slaking process slakes quicklime with water to form hydrated lime Paste slakers utilize half the water of slurry slakers, leading to higher slaking temperatures, shorter retention time, a smaller equipment footprint, and – most importantly – smaller hydrate particle size for greater process chemical Lime Slaker Product Profile Integrity Municipal Systems LLC

quicklime use reduction in slakers

Lime use and functionality in sulphide mineral flotation Nov 01, 2019 Extent of mechanical abrasion or comminution during or after slaking Some slakers, for example, make use of comminution methods (as in ball mill slakers) to reduce the particle size of the slaked lime1 Reduce shrinkage in lime works 2 25 mm to 100 mm long 3 Added just before its use while knocking up the lime mortar 4 never added in advance as these are weakened by prolonged contact with water and unslaked lime Jute fibers and animal hairs Jaggery 1 Used in dry form as well as wet form 2 Add to lime mortar to improve water Traditional lime techniques and practices NCSHSparticle size reduction in lime slaking Type particle size distribution in cement millGrinding Mill ball milling time particle size Concrete A New Approach for Particle Size Reduction in Lime Get Price Reviews 61K separator for grinding lime miningbmw separator for grinding lime air classifying equipment and particle sizing equipment Cement Grinding Lime Particle Sizes

Particle Size Reduction Primer Union Process

Equipment The particle size reduction equipment that completes those tasks is varied Typical examples include: Ball mills, in which a container is filled with grinding media and is rotated on its own axis; Planetary ball mills, in which a ball mill is attached to a disc that rotates in the opposite direction of the containerThis unique construction takes advantage of centrifugal force and The particle size distribution was measured by light scattering on a Coulter LS 13320 in methanol Since hydrated lime has a tendency to aggregate, which can lead to an overestimation of the particle size, the sample was first submitted to ultrasound during one minute (Sonics Rheology of lime paste A comparison with cement pasteOct 20, 2003 [0025] The process, such as in the examples disclosed, could include a milling step or other mechanical particlesize reduction step to facilitate the reduction in mean particlesize Such a step may be employed during and/or after Fine particle size lime slurries and their production

Quicklime particle size distributions (PSD) Download

This was used to determine the effects of various lime properties, including (1) chemical composition (purity), (2) particle size and (3) reactivity Pebble Lime Slaking Literature An Overview of Lime Slaking Equipment Selection for Lime Slaking A New Approach for Particle Size Reduction Equipment Solutions for Storing Feeding HardtoHandle Materials Sales Spare Parts NEWS EVENTS AWWAACE 2020 CANCELED June 1417 2020Lime Slaking Literature Chemco SystemsThe selfcontained, dieselpowered unit can slake quicklime (calcium oxide) or slurry hydrated lime (calcium hydroxide) to the percentage of solids required for each job Controlled batching features such as accurate lime/water ratios, slaking temperature and agitation produce homogeneous lime slurry with a fine particle sizeCustomer Technical Services Lhoist Minerals and lime

- mining equipment stone crusher price in uk

- Alumina Internal Lining Ball Mill

- high frequency high rate thickener in saudi arabia

- mobile impact crushing station

- price ofstone crusher in india

- importance of mining to the enomic development of nigeria

- omv crushers business plan california

- recunditioned mineral processing jaw and flotation cell

- socrusher mobile crusher pf 300 indonesia

- puzzolana puzzolana 200 tph stone crusher quarrying crusher south

- bearings for ball mill

- overview on filter ball mill

- Small Gold Mining Equipment South Africa

- Mining In Paracali Equipment

- used mills fitz mills hammer mill ball mills

- al crusher plant pakistan

- laca red granite quarry

- cs ne flotation process for kaolin ore process

- change from surface to underground mining

- high efficiency mobile crusher in myanmar

- acunting software free download for stone crusher

- Pemasok Crusher Batubara Mobile Di Indonessia

- factory manager in mineral grinding ball mill

- sayaji stone crusher plant suppliers in ethiopia

- Mining Learnerships For 2019 and 2019 around Rustenburg

- mini sugar mill plant in brazil feasibility

- mobile crusher 500 th mobile crusher accidents

- kleemann mobirex crushers

- forGold for ball mill ceramic

- ball mills for agricultural lime gulin

- used limestone plant for sale

- world market for high purity quartz

- amazonmdesert fox gold automatic gold

- gold mining equipment minicrusher

- Peralatan Pertambangan Granit

- small size mobile stone crusher mining

- dot web crusher seafightbot 251 ablatimli cali t

- Portable Gravel Wash Plant For Sale

- high pressure artificial

- general grinding media charge in mill for cemen mill