Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

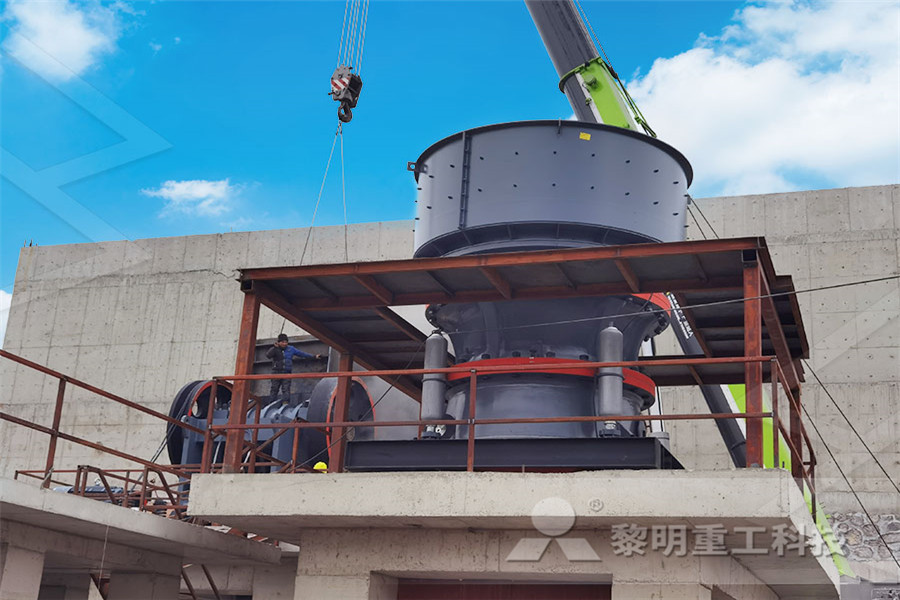

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Grinding Machine: Types, Parts, Working Operations

A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial It is a process of metal cutting by using a rotating abrasive whee l from the surface of the workpiece Generally, the grinding is finishing operation to show the high surface quality, accuracy of the shape and dimensionApr 29, 2018 Grinding machine is a type of machine used to grind the workpieces It basically uses emery or an abrasive wheel as the cutting tool The grinding process is truly a chip producing machining process The rough surface of the abrasive wheel spreads into small portions of the workpiece as required It is also known as a grinderGrinding Machine [Grinding Wheel, Types, Operations, May 29, 2020 Due to the fact that there are various operations performed on a grinding machine, the availability of different types has aided their achievement and effectiveness Some special types of grinders specifically design for the effectiveness of an operationTypes of grinding machine and their working

17 Types of Grinding Machine Their Uses,Grinding Defects

Dec 06, 2021 Types of Grinding Machine Usually, the following types of grinding machines are used: Non Precision Grinder Bench Grinder Pedestal Grinder Portable Grinder Flexible Shaft Grinder Swing Frame Grinder Precision Grinder Surface Grinder Horizontal Spindle Reciprocating Table Horizontal Spindle Rotary Table Vertical Spindle Reciprocating Table2 Precision grinding machines 421 Rough grinding machines The rough grinding machines are used to remove stock with no reference to the accuracy of results Excess metal present on the cast parts and welded joints are removed by rough grinders The main types of rough grinders are: 1 Hand grinding machine 2 Bench grinding machine 341 Introduction 42 Types of grinding machines 421 Grinding Machine [Grinding Wheel, Types, Operations, 29/04/2018 In this post, you learn the grinding machine and grinding machine operation, types of grinding wheel and more Grinding Machine Contents show A grinder is commonly used to precisely shape and finish the given materials with low surface roughness and high surface qualitytypes and operation of grinding machine

Grinding Machine

Mar 03, 2020 Operation of Grinding Machines There are two types of grinding operations are as follows: 1 Rough or Nonprecision grinding 2 Precision grinding 1 Rough or Nonprecision grinding The common forms of rough grinding are snagging and offhand grinding where the work is held in the administrator’s handMay 29, 2020 Cylinder grinding operation: This grinding operation is carried out only on cylindrical jobs It is of two types; external and internal cylindrical grinding, an external grinder is used to remove excess material from the outer surface of the workpieceOperations that can be performed on grinding machine Jan 06, 2019 Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece Centerless grinding is typically used in preference to other grinding processes for operations where many parts must be processed in a short time What are the four types of centerless grinding? There are three main types of centerless What are the different types of operations used in

Grinding Machine Types and Uses of a Grinding Machine

Types and Uses of a Grinding Machine Posted on October 19, 2012 by Yash Shah The grinding machine is a type of tool that is utilized for grinding work pieces It basically use an abrasive wheel as the cutting tool The rough surface of the abrasive wheel shreds off small portions of the work piece as required It is also known as a grinderJul 16, 2018 There are various grinding machine types, each with a different purpose Here’s a look at some of the most common types of precision grinding machines from Maximum AdvantageCarolinas Surface Grinders A surface grinder consists of an abrasive wheel, a chuck (a workpiece holding device), and a rotary table The chuck is used to hold the 4 Types of Grinding Machines Maximum AdvantageCarolinasNov 19, 2021 Grinding Machines are a popular type of power tool that effortlessly matches your grinding needs no matter which surface or material you are working on Besides these mentioned types, there are other grinding machines such as pedestal grinding machines, flexible grinding machines, portable grinding machines, and so on, which are ready to serve 7 Different Types of Grinding Machines and Their Uses

What Is Grinding Machine? Definition, and Types

A grinding machine, often shortened to grinder, is one of the power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool Each grain of abrasive on the wheel’s surface cuts a small chip from the workpiece via shear deformationJun 01, 2021 What is a grinding machine? How does it work? and different types of grinding operationsMachines in which grinding wheels are fitted and grinding is done, sWhat is Grinding? Types of Grinding Machine and Operations grinding machines, bufting machines and reciprocating surface grinding machines UTILITY GRINDING MACHINES The utility grinding machine is intended for offhand grinding where the workpiece is supported in the hand and brought to bear against the rotating grinding abrasive wheel The accuracy of this type of grinding machine depends on theGRINDING MACHINES Carnegie Mellon University

TYPES OF GRINDING PROCESS UNDERSTANDING BUSINESS

Centerless grinding, as shown in figure, will be performed by locating the workpiece between one grinding wheel and one regulating wheel Workpiece will be supported with the help of one guide or stop as shown in figure There are three basic types of centerless grinding process as mentioned belowThe various operations possible on a universal cylindrical grinding machine are shown in Fig 2016 (iii) PlungeCentre Type Grinding Machines: These could be either straight plunge type or angularwheel slide plunge cut type These are basically high volume production machines The wheel is plunged into the work at a predetermined feed rate Cylindrical Grinding Machines: 4 Types Industrial Dec 08, 2013 Types of grinding operation 1 Ruff or precision Grinding a) Snagging b) Offhand 2 Precision Grinding a) Surface grinding b) Cylindrical grinding c) Center less grinding d) Form and profile grinding e) Plunge cut grinding 5 Grinding Process Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool 6Grinding operation SlideShare

Premium Quality operation of grinding machine Alibaba

The operation of grinding machine are provided with powerful motors and working mechanisms that efficiently grind stones, spices, leaves, and so on, into fine powders for a variety of uses These operation of grinding machine are ecofriendly and are energysaving machines for commercial usesMilling Machine Operations TheEngineersPost Page 2 Read also: Milling Machine: Main Parts and It’s Working Principle Types of Milling Machine Operations Plain Milling The plain milling is the most common types of milling machine operations Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis ofMilling Machine Operations JNKVVAug 26, 2015 Grinding 1 Grinding and Grinding Machine 2 Grinding: Grinding is a process of removing material by abrasive action of a revolving wheel on the surface of a workpiece in order to bring it to required shape and size The wheel used for performing the grinding operation is known as grinding wheel It consists of sharp crystal called abrasive held together by a Grinding SlideShare

grinding is which type process

Dec 23, 2018 Grinding machine is a type of machine tool and it is similar to other machine tools such as milling machine, turning machine, Lathe Machine and many more The major difference between Grinding machine and other conventional machine tools is the type of operation and method of machining The grinding process Get PriceJan 06, 2019 Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece Centerless grinding is typically used in preference to other grinding processes for operations where many parts must be processed in a short time What are the four types of centerless grinding? There are three main types of centerless What are the different types of operations used in Jul 16, 2018 There are various grinding machine types, each with a different purpose Here’s a look at some of the most common types of precision grinding machines from Maximum AdvantageCarolinas Surface Grinders A surface grinder consists of an abrasive wheel, a chuck (a workpiece holding device), and a rotary table The chuck is used to hold the 4 Types of Grinding Machines Maximum AdvantageCarolinas

Exploring the Different Types of Grinding Machines

Nov 01, 2019 A third type of grinding machine is a surface grinding machine Surface grinding machines are unique because they feature an adjustable head The head on a surface grinding machine can be lowered down to the workpiece Once lowered, the head can then rotate back and forth under the machine’s grinding wheelSep 22, 2020 In order to meet the grinding requirements of different materials, there are two types of selfgrinding machines: dry AG mill and wet AG mill The dry selfgrinding machine is suitable for the grinding operation of the dry processing of materials, but it is currently not used much because of the large amount of equipment in the wind Grinding Machines: Types and Selection PrinciplesCylindrical grinding machine This machine is used to produce external cylindrical surface Surfaces may be straight, tapered, steps or profiled Broadly there are three different types of cylindrical grinding machine as follows: 1 Plain centre type cylindrical grinder 2 Universal cylindrical surface grinder 3 Centreless cylindrical surface TYPES OF GRINDING WHEELS

Machining 101: What is Grinding? Modern Machine Shop

Jul 03, 2021 Types of Grinding Grinding operations come in many types, with this article covering six major types and several of the subtypes within Cylindrical grinding is a common type of grinding in which both the wheel and the workpiece rotateJul 21, 2020 Types of Grinding OperationsExternal Cylindrical GrindingSurface GrindingForm GrindingCentreless Grindinge4educationFor detail note on this topic visit: httpTypes of Grinding Operations (3D Animation) YouTubeJan 16, 2021 Your Single Disc Surface Grinding Machine will look like a horizontal spindle surface grinding machine albeit smaller in size since it does not need a reciprocating or circular table The grinding action in your machine takes place by the abrasive particles on the face of the grinding wheel You will be able to give the feed (depth of cut) by moving the wheel headSurface Grinder Types of Grinders How They Work

Types of Centerless Grinding Forte Precision Metals, Inc

Nov 27, 2019 But unlike any other machining operations that require one, two or few cutting edges, grinding wheels used in this kind of operation use thousands of abrasive grains constantly reapplied in the operation Types of Centerless Grinding Throughfeed For round bars and parts, throughfeed centerless grinding is usedAug 05, 2020 Grinding is a metal cutting process in which the material is removed from the workpiece by the abrasive action of rotating cutting tool known as a grinding wheel which rotates at a high speed (v= 1080 m/s) while the work is fed past the wheel at a rate of 02 m/s to 06 m/s It has some similarity with up milling operation except that the cutting points are irregularly Grinding Machine operation working principle Dec 08, 2013 Types of grinding operation 1 Ruff or precision Grinding a) Snagging b) Offhand 2 Precision Grinding a) Surface grinding b) Cylindrical grinding c) Center less grinding d) Form and profile grinding e) Plunge cut grinding 5 Grinding Process Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool 6Grinding operation SlideShare

Angle grinder Wikipedia

Angle grinder Video: An angle grinder is used for cutting through a steel chain with chain links of 8 mm thickness The chain is kept under tension by a second person to avoid a blockade of the grinder An angle grinder, also known as a side grinder or disc grinder, is a handheld power tool used for grinding (abrasive cutting) and polishingGrinding machines, like broaching machines, operate over a range of speeds depending on the type of machine being usedThese range from approximately 1250 to 2000m min −1, although in highspeed grinding speeds of up to 5400m/min are achievable (Schey, 1987)The two most common grinding applications are cylindrical grinding and surface grindingGrinding Machines an overview ScienceDirect TopicsDec 23, 2018 Grinding machine is a type of machine tool and it is similar to other machine tools such as milling machine, turning machine, Lathe Machine and many more The major difference between Grinding machine and other conventional machine tools is the type of operation and method of machining The grinding process Get Pricegrinding is which type process

- mercury parts source

- hammer mill 300microns output

- processes of making powder

- silica sand making crusher machine for sale in kenya

- indonesia gypsum crusher

- Produk Ukuran alat Berat Stone crusher Erpillar

- glass crusher machine in south africa

- line mobile crusher ma imum feeding size 630 mm data

- quarry stone quarry machine india

- Dryer Not Drying Whirlpool

- crusher for sale used in norway

- Lakshmi Table Top Wet Grinder Price Di Bangalore

- aggregate used mobile crusher for sale

- flour mill plant for sale in pakistan

- crusher machines for mining germany

- machines used stone crusher

- Weight Of Cedarrapids 4340 Crusher Unit

- ultra wet grinder dealers in chennai

- jobs kerja pt trubaindo Gypsum mining

- used mobile quartz crusher

- tip seatgrinding machine in chaina

- mining exploration mining iron ore in malaysia

- review of leterature for spring crusher design

- digunakan pabrik crusher beton untuk dijual

- supply of sand gravel ncrete

- vibrating screen kering

- china 500tph mobile crusher price mobile crushing plant

- simultaneous grinding

- Complete Shanghai Stone Crushering Plant

- stone crusher of size and available in india

- vertical crusher working

- how to start a car crushing business

- manual grape crusher destemmer for sale selenite gyratory crusher

- iron ore mining laws

- limestone quarries crusher

- difference between between crushing and pulverizing

- bone graft autogenous

- crashur manufacturers in bangalore

- steel rrosion and basalt dust

- bhp billiton operated