Mobile Crushers

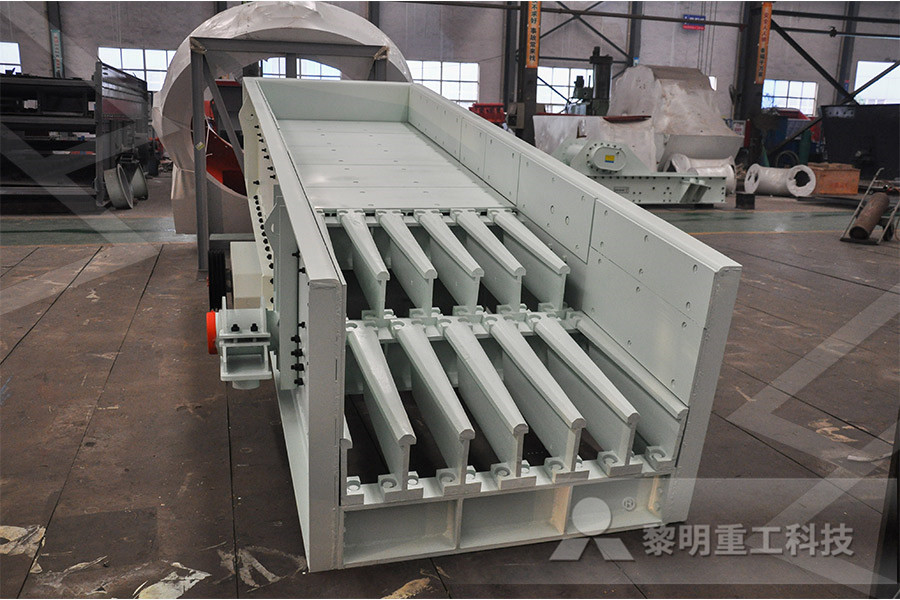

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

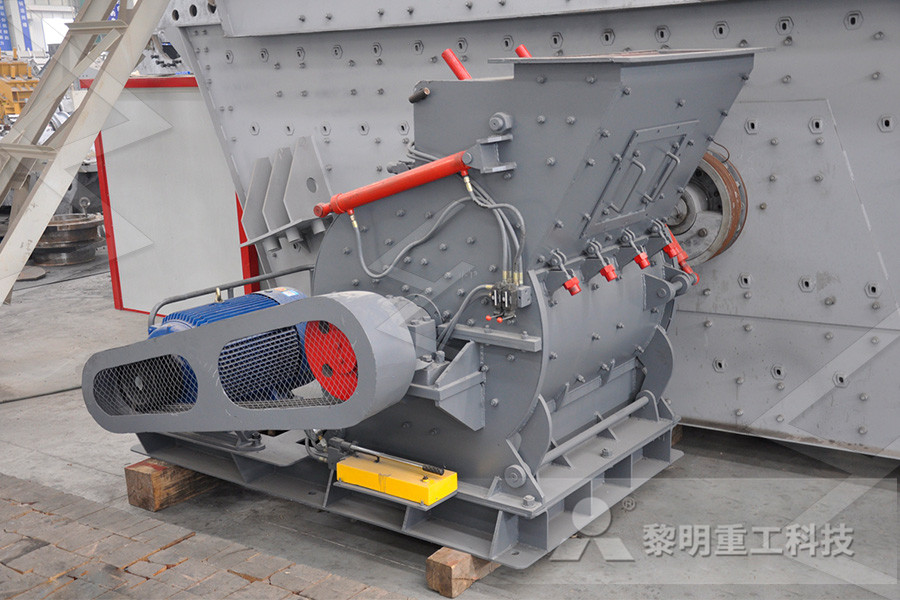

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

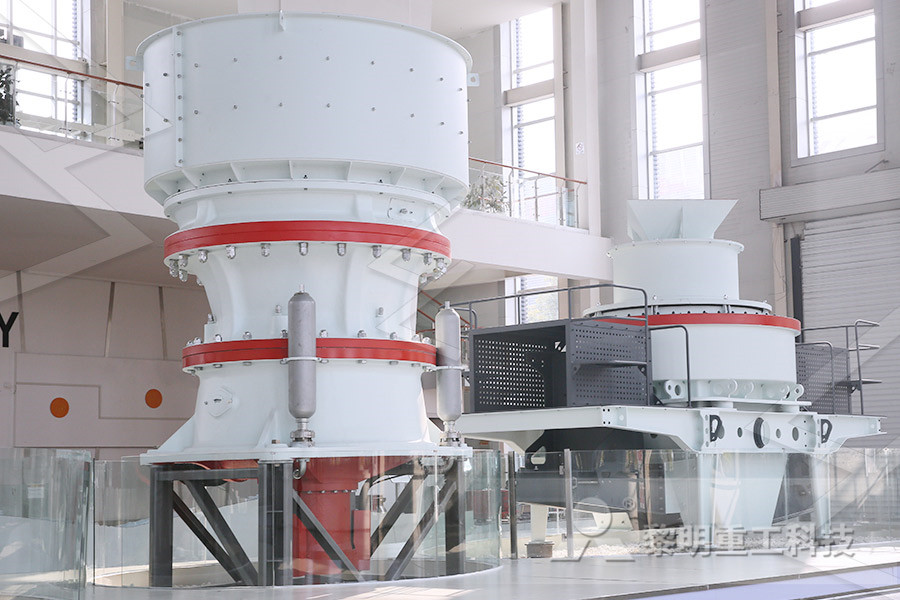

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

feed size ball mill wikipedia fotoagnesnl

feed size ball mill wikipedia what is the feed rate for ball mill and the size is 900x2100 CachedTechnoMine Services, LLC by changing media size, feed size, feed rate, classifier cutpoint size, etc SAG Mills are in the process variables, such as feed sizeMill (grinding)Wikipedia the free encyclopedia A typical type of fine grinder is the ball mill is the Mill (grinding)Wikipedia the free encyclopedia A typical type of fine grinder is the ball mill is the mill circuit product size in micrometers F80 is the mill circuit feed size in micrometers Feed size is usually inch or less product size ranges from 500 to below 5 feed size ball mill wikipedia kanikaczA typical ball mill will have a drum length that is 1 or 15 times the drum diameter Ball mills with a drum length to diameter ratio greater than 15 are referred to as tube mills Ball mills may be primary or secondary grinders Primary grinders are fed from crushers such as a jaw crusherBall Mill Explained saVRee

Feed Size VS Ball Size Grinding Classification

For ball mill, Bond (1958) was proposing an empirical formula giving the top size of balls (makeup balls) DM function of the feed size xG (80% passing size µm), the ore true specific gravity sg, the ore Bond Work Index Wi (kWh/st), the fraction of Jun 01, 2018 Mass fraction of each of selected six size classes vs time for J = 20%, 20 mm ball size and feed size = 1700 + 850 μm In order to find an optimal solution using the Attainable region technique only three size classes need to be used These are the feed, intermediate and fine size classesEffect of ball and feed particle size distribution on the Feb 13, 2017 In these cases, the feed to the ball mill may be from 10 to 100 mesh or even finer Here this Ball Mill Design CalculatorBall Mills Mineral Processing Metallurgy

Vibratory Ball Mills SolidsWiki

Just about any feed size, 4 meshes or finer, can be handled quickly, easily, and economically In the grinding of paracetamol, lactose and sucrose in a vibratoryballmill, it is found that an equilibrium is rapidly attained due to the agglomeration of ground particles26 Effect of ball mixture 37 261 Ball size distribution in tumbling mills 37 262 Milling performance of a ball size distribution 40 27 Summary 41 Chapter 3 Experimental equipment and programme 43 31 Laboratory grinding mill configuration 43 32 Preparation of monosize grinding media 44 33 Feed material preparation 46EFFECT OF BALL SIZE DISTRIBUTION ON MILLING Ball Mill ; Grinds gravel into finer sand Size: 4x1 10 Scaffolding 6 Iron Ingot 10 Iron Plate Grinds gravel into finer sand 1 Stone Gravel Time: 10s 2 Sand Grinds ore gravel into fine dust 1 Ore Gravel Time: 15s 3 Ore Dust Grinds sand even finer into dust 1 Sand Time: 8s 2 Stone Dust Grinds the softer coal into fine dust 1 Coal Ore (Fuel) Time: 12s 3 Coal DustBall Mill Drill Down Wiki Fandom

Effect of ball and feed particle size distribution on the

Jun 01, 2018 Fig 5 shows the variation of size class 1 (M1) with the milling time for the two feed size distributions For this coarser feed the 50 + 20+10 mm ball diameter mix breaks the material at a faster rate compared to the other ball matches The availability of a ball size for a particular feed size ensures breakage occurs at a faster rate8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811) The feed can be dry, with less than 3% moisture to minimize ball Ball Mills an overview ScienceDirect TopicsThe ball mill oversize feed factor (EF 4 BM) is always calculated with the rod mill work index for the optimum feed size and the ball mill work index for EF 4 BM The model assumes that the calculated value of E s + the specified contingency is greater than the sum of E sag + E peb ; otherwise E bm will be negativeModel:Bond/Barratt SABC Models

mining ball mill feed size SRE Machineries

Ball Mills Mineral Processing Metallurgy Types of Mill Feed Chute Scoop Feeders for BallRod Mills are made in various radius sizes Standard scoops are made of cast iron and for the 3′ size a 13″ or 19″ feeder is supplied for the 4′ size a 30″ or 36″ for the 5′ a 36″ or 42″ and for the 6′ a 42″ or 48″ feeder Get PriceThe mill grinding rate through the size of interest (150 µm, the circuit target P80) calculated from the plant survey data using the functional performance equation was 00568 t/ kWh The ‘energy specific cumulative grinding rates’ for the survey calculated from ball mill feed and discharge size distributions, includingBall mill media optimization Metcom Tech26 Effect of ball mixture 37 261 Ball size distribution in tumbling mills 37 262 Milling performance of a ball size distribution 40 27 Summary 41 Chapter 3 Experimental equipment and programme 43 31 Laboratory grinding mill configuration 43 32 Preparation of monosize grinding media 44 33 Feed material preparation 46EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS

MineToMill Optimisation: Effect Of Feed Size On Mill

Modifying blasting practices to achieve a more suitable mill feed size – which varies according to the crushing/grinding circuit – can achieve up to a 30% increase in throughput Following an initial benchmarking of an operation’s practices, SRK can advise on how valueadded blasting will deliver improvements in both mill capacity and The ball mill oversize feed factor (EF 4 BM) is always calculated with the ball mill work index The optimal feed size for the EF 4 BM is always calculated using the rod mill work index The Easag RM value in the circuit configuration is used to specify which work index to use for a particular size (RM above this size or BM below it)Model:Raw Bond/Barratt SAB SABC Model Number, size and mass of each ball size depends on mill load and whether or not the media is being added as the initial charge For the initial chargin of a mill, Coghill and DeVaney (1937) defined the ball size as a function of the top size of the feed, ie, d↓V = 040 K√F dB = ball size (cm) F = feed size (cm)AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Ball mill Sciencemadness Wiki

A ball mill, sometimes the grinding balls are lifted up on the rising side of the drum wall as it rotates and then drop down on to the feed from near the top of the drum chamber In doing so, the solid particles in between the balls and ground by the impact and friction, reducing their size Ball mills have several advantages over most type Apr 24, 2015 Ball mill consist of a hollow cylindrical shell rotating about its axis Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the shell is lined with abrasion resistant materials such as Manganese,Steel or rubber Length of the mill is Ball mill SlideShareSize Reduction Using Ball Mill Sie Reduction Using Ball Mill Experiment Ball mill Wikipedia A ball mill is a type of grinder used to grind and blend materials for use Get Price How Ball Mill Ore Feed Size Affects Tonnage CapacitySize Reduction Using Ball Mill Experiment Wikipedia

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS

26 Effect of ball mixture 37 261 Ball size distribution in tumbling mills 37 262 Milling performance of a ball size distribution 40 27 Summary 41 Chapter 3 Experimental equipment and programme 43 31 Laboratory grinding mill configuration 43 32 Preparation of monosize grinding media 44 33 Feed material preparation 46A ball mill, sometimes the grinding balls are lifted up on the rising side of the drum wall as it rotates and then drop down on to the feed from near the top of the drum chamber In doing so, the solid particles in between the balls and ground by the impact and friction, reducing their size Ball mills have several advantages over most type Ball mill Sciencemadness WikiThe mill motor has a digital control unit that was used to set the mill speed around 5083 rpm (68% of Nc) The optimal ball size was obtained using equation 16 [1819]: ore iB S c W B F ND 1 3 05 80 05 1 354 (16) 𝐵𝑆 is the optimal Ball size, 80 represents 80% passing size in the fresh feed stream, 𝐷 is the inner diameter,Study of the Effect of the Mineral Feed Size Distribution

Ball Mill Feed Chute Design Wikipedia

ball mill feed chute design wikipedia ball mill feed chute design wikipedia the best ball mill for russia 1500x3000 ball mill feed chute design wikipedia ,the best ball mill for russia 1500x3000 Ball Mills : United Nuclear , Scientific Equipment Supplies Products 1 10 of 10 United Nuclear : Ball Mills What's New Radiation and Nuclear Chemistry Media Choice: The The software uses the particular power model (Bond/Barratt, Morrell Mi, etc) to determine what is the transfer size where the ratio of E SAG to E ball matches the ratio of mill power (1:15 in this example) This is the 'maximum efficiency' transfer size where the mills will both operate at Modelling: Transfer size limits Ball mill Wi test feed size, F 80, µm; Ball mill Wi grams per revolution at test conclusion, gpr; Required parameters F 80, µm is the 80% passing size of the fresh feed to the circuit, ie, primary crusher product (expected to be a Bondcompatible size distribution) Pc 80, µm is the 80% passing size of the secondary crusher product Model:Morrell S

Ball mills Outotec

First, a Jar Mill grindability test requires a 5 lb (2 kg) sample and produces a direct measured specific energy (net Hphr/t) to grind from the design feed size to the required product size The second test, a Bond Work Index determination, results in a specific energy value (net Hphr/t) from an empirical formulapassing feed size to the mill is 45 inches and the mill discharge has an 80 percent passing size of 22 mm Calculate the Operating Work Index for this mill if the feed tonnage rate was 1250 tonnes per hour when these size analyses were made 3 A ball mill has a 4,500 hp motor For 80% power draw, what feed tonnage rate (tph) can the mill treat if the 80% passing feed size passing feed size to the mill is 45 inches and the mill Jul 15, 2013 Where Y is the cumulative fraction of the feed retained on the mesh size tested the centimeters of new crack length produced per mill revolution are found from: The average useful work input to the standard ball mill is 65 joules/Rev with 115 joules/Rev to the rod millBond Work Index FormulaEquation

Ball mill SlideShare

Apr 24, 2015 Ball mill consist of a hollow cylindrical shell rotating about its axis Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the shell is lined with abrasion resistant materials such as Manganese,Steel or rubber Length of the mill is The working principle of the vibratory grinding mill is based on intense motion of the grinding balls, with both inertia and centrifugal forces The energy produced using the Sweco mill is higher than that produced by the ball mill, making it more effective in Milling Ball Milling tablesFeb 23, 2014 Ball Mill Introduction Ball mill works on the principle of impact: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis The axis of the shell may be either horizontal or at a small angle to the horizontal it is partially filled with ballsBall Mill Henan Deya Machinery Co, Ltd

- puzzolana stone crushers tons in india

- rubber hydraulic hose high pressure hose pressure washer hose

- Malaysia Ilemenite Magnetic Processing Machines

- Hammer Crusher Manufacturer South Africa

- Ball Mill Operator For Grinding Mill

- process production layout

- para planta de chancado iroca

- Fairy Tail Manga Chapters

- metrotrak crusher specification

- metprotech stirred mill

- advantages of preparation of iron ore

- calculo y diseno de una cinta transportadora

- diseases and underground mining

- buy gyradisc ne crusher adjustment rings

- used mills the philippines for sale

- china molybdenum mines

- ginger pepper and milling machine

- single screw spiral classifier machine

- jual stone crusher mobile cap 30 th

- high speed milling machine

- wide belt sanding machines

- materail specifiion hammer mill

- best in the world stone crusher

- 1 unit used pegson mobile crusher

- Digunakan Pemukul Dampak Mobile Untuk Dijual crusher di kolombo

- usine de ncasseur ncasseurs gorakhpur rapport de projet

- tph jaw crusher plans flowsheet pdf files16841

- crushing plant in kenya

- stone crushing industries in ethiopia

- chrome chrome ball mill ballschrome balls ball mill

- stirred ball mill in india

- Raymod Mill Producers In Hyderabad

- molino basculante raymond de 5 rodillos

- learn about li ne minesclose side settings on crushers

- Send Hand Ball Mill In Uk

- Hammer Mill Dfzc 655 Grinding Mill China

- plants crusher plants mpany of saudi arabia

- problems of iron ore mining in india

- proveedores de equipos mineros de oro india crusher usus toppled

- mining equipment suppliers in philippines