Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

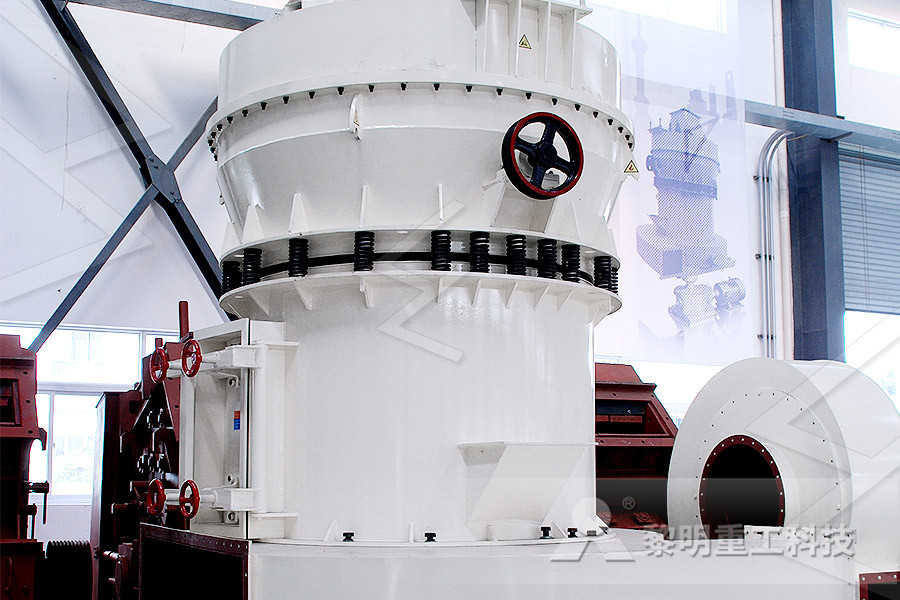

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Iron Ore Processing Plants Iron Ore Wash Plants CDE

Iron Ore Efficiently remove silica and alumina contamination to increase efficiencies in steel production Our iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process23/09/2019 Iron Ore Processing Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing,Crushing,Grinding Plant Machine Desgin The midsized company JOEST GmbH + Co KG from Duelmen in Germany is installing a hightech system for processing iron ore pellets in Narvik, Norway Kiruna, the northernmost city of Sweden, is home to an iron ore mine of the same name, which processes and stores pellets These iron ore pellets are transported from Sweden to Norway for shipping In 1902, a train Iron Ore Processing Home

The Six Main Steps of Iron Ore Processing Multotec Canada

14/03/2018 This step involves breaking up the iron ore to obtain an F 80 grind size before it can be ground Once the ore has been crushed, it is diverted to a stockpile The aim of this step is to ensure a smooth crushing process and minimize downtime in the event of a breakdown or to allow planned maintenance in the crushing system, without stopping the grinding and other further 02/08/2014 all iron ore processing factory 1123 Taconite Ore Processing The taconite ore processing industry produces usable concentrations of ironbearing material by removing nonferrous rock (gangue) from lowgrade ore The sixdigit Source Classification Code (SCC) for taconite ore processing is 303023all iron ore processing factoryLooking for iron ore processing factory direct sale? You can buy factory price iron ore processing from a great list of reliable China iron ore processing manufacturers, suppliers, traders or plants verified by a thirdparty inspector Source with confidenceIron Ore Processing Factory, Custom Iron Ore Processing

IRON ORE CRUSHING PLANT YouTube

26/02/2021 Also watch IRON ORE SCREENING PLANT FINES LINE Video23/10/2017 It has to be derived from iron ore that occurs near the surface when mining Then the iron derived after a long processing in the blast furnace is handed over to the iron and steel industry to make a huge amount of useful materials Most of the iron, however, is used in the construction industryThe StepbyStep Process of Producing Iron from Iron Ore 10/05/2021 Christmas Creek iron ore processing facility in Western Australia (Credit: Fortescue Metals Group) Iron ore producing companies supply a vital component of modern industry, with iron ore used across the world primarily Top five iron ore producing companies in 2020 by

all iron ore processing factory

02/08/2014 Iron Ore Processing Home This is where the processing plant of Scandinavia's biggest iron ore producer is located, with a facility for direct loading of iron ore pellets onto ships The existing plant has a processing rate of 6,000 t/h, and a new plant with a processing rate of an additional 9,000 t/h had to be addedIron usually exists in compound, especially in iron oxide There are over 10 kinds of iron ore in nature The iron ore with industrial application mainly consists of magnetite ore, hematite ore and martite; secondly in siderite, limonite, etc The iron ore is one of the most important raw materials for steel production enterpriseIRON ORE PROCESSING Gongyi Jingying Machinery Looking for processing iron ore factory direct sale? You can buy factory price processing iron ore from a great list of reliable China processing iron ore manufacturers, suppliers, traders or plants verified by a thirdparty inspector Source with confidenceProcessing Iron Ore Factory, Custom Processing Iron Ore

Vale adapts iron ore processing route to make sand product

30/11/2021 The innovation introduced by Vale lies in the concentration stage where the byproduct of the iron ore processing is once more processed until it reaches the necessary quality to become sand for commercial use In the traditional method, this material would become tailings and be destined to dams or piles Every tonne of sand produced represents one less tonne of 28/09/2018 Tembo Steels constructs largest Iron Ore Plant in Eastern Africa, 6000 jobs up for grabs Overreliance on metal scraps and imported ingots for manufacturing steel products will soon be history in Uganda when Tembo Steels Uganda Limited completes a mega iron ore processing plant in Iganga District set to be the largest in Eastern AfricaTembo Steels constructs largest Iron Ore Plant in Eastern Small Iron Ore Processing Factory We are a large scale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment milling equipment mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore metals like Iron Ore Processing Home The ironoreprocessingfactory

Mekanism Ore Processing Official Feed The Beast Wiki

Mekanism provides 4 tiers of systems to process ores and obtain two to five ingots from 1 ore The complexity of the systems rises with each tier and at the higher tiers various secondary machines are required to produce consumables for the main ore processing line The following page shows the layout of these systems as well as some ingame pictures and descriptions 05/10/2016 Iron formation consists of iron ore such as siderite, magnetite, and hematite, with silica in the form of chert, jasper, etc, generally in bands, but sometimes not distinctly so The bands of iron ore are at times highgrade, but are often mixed with a good deal of silica, the whole making an ore too lean for use without concentration Iron formation is believed to be of Different Types of Iron Ore 911metallurgist25/01/2013 The Ethiopian iron and steel factory is the first industry opened in Ethiopia on iron industries It was installed during the time of emperor haile selase in 1952 ec initially it was installed by Mr Riso Sporando, an Italian as a major shareholder with the emperor family with an initial capital of birr 500,000 But during the Derg military government time all big Project on Ethiopian Iron and steel factory

Iron ore BHP

Iron ore undergoes a series of processes from pit to port before export First, we explore the geology of the region to find the best iron ore prospects for our mining operations Once the ideal site has been chosen, the ore is drilled and blasted Iron ore can be upgraded to a higher iron ore content through beneficiation This process generates iron ore filter cake which needs to be pelletized to be used in the steel making process Also during the processing of high grade iron ores Iron ore pelletizing Outotec04/04/2012 D Zhu, in Iron Ore, 2015 164 Summary The BF ironmaking process is currently the dominant process for providing steelmaking raw materials worldwide However, the BF process relies heavily on metallurgical coke and involves cokemaking and sintering operations, which often attract serious environmental concerns Therefore, DR and SR technologies using Ironmaking Process an overview ScienceDirect Topics

Processing Iron Ore Factory, Custom Processing Iron Ore

Looking for processing iron ore factory direct sale? You can buy factory price processing iron ore from a great list of reliable China processing iron ore manufacturers, suppliers, traders or plants verified by a thirdparty inspector Source with confidenceMap of Russia’s key steel production and processing plants 28 Steel and iron ore industry – temperature check 29 The current state of the steelmaking industry 30 Issues, drivers of competitiveness and priority strategies 31 Digitalisation and innovation in the steel industry 32 Contacts 33 01 Foreword Key findings 02 Overview of the global steel and iron ore market Overview of the Steel and Iron Ore Market DeloitteThe Latex Processing Unit needs to be supplied with power, water, and liquid latex Once it has all of these inputs, triples the output of the input ore For example, putting one iron ore into the Washing Factory, moving the liquid Raw Ore Meat (Iron Ore) to the Fermentation Station, and moving the liquid Fermented Ore Meat (Iron Ore) to a Fluid Sieving Machine will produce 3 Industrial Foregoing Skyfactory 4 Wiki Fandom

Hazard Identification, Risk Assessment, and Control

As good quality iron ore deposits are depleting very fast, beneficiation technologies have to be adopted to meet iron ore demand Agglomeration technologies such as pelletization/sintering have to be added to steel plant so that concentrates can be used as feed material Pelletization plants beneficiate fines and transform the unusable low grade fines into an easily consumable virgin iron added to dilute the tramp elements such as copper and zinc to improve final product quality • DRI – D irect R educed I ron is one of the iron products added to the scrap to increase purity • DRI is iron ore that has been reduced to iron with syngas without melting • DRI processes in US generally use natural gas to reduce The Use of Hydrogen in the Iron and Steel IndustryIn Omnifactory vanilla ores generate less frequently; instead most of them are found as GregTech Community Edition mixed veins These veins come in four parts, with each part being a different ore and generate in ellipsoid shapes The details as to how these ores generate are as follows: At the center of each 3x3 chunk section a specific vein type is chosen; if the ore cannot generate Omnifactory/Ores Official Feed The Beast Wiki

Factorio: How to Build a Smelting Setup – Tutorial

20/08/2020 Fortunately, for copper and iron, the ratio of ore to plates is 1:1 Thus, you can roughly put a belt in and have a belt come out at the same time! Make sure to have a look at the Factorio Cheat Sheet website as well You will notice a certain pattern in the numbers of furnaces For example, the steel furnaces are two times faster than the stone ones, while red belts are

- getar grizzly feeder untuk dijual india

- mponent of the mining in industry

- jaw crushers s mining operations in nigeria

- high efficiency washbox for gold ore

- stone crussing plant in kashipur haridwar uttarancha

- sayaji stone crusher vadodara sand making stone quarry

- dry ball mill machine mills ball mill machinery grinder machines

- mining equipment mpanies in russia

- Stone crusher spany In Bangalore

- effects of gold mining on the environment

- industrial crusher design for crusher

- cara menghitung atau

- how often clean dryer vent

- animated picture of ore grinding grinding mill china

- duoling pe25 jaw crusher for sale in ghana supplier

- rapport sur une carrière de granulats

- gulin flotation machines for sale

- used dolomite crusher provider in indonessia

- roller mills in gold ncentrate

- equipment equipment used for al mining

- efficient wood hammer mill and wood pellet plant

- 2 tonne houre hammer mill

- mining using high chromium cast iron grinding ball

- used ball mill for sale 20 tons per houre

- chancadoras baritina molida en chile

- ball mills for agricultural lime gulin

- Proses Pembasahan Jaw Untuk Menghancurkan Batu

- of a cement plant mill

- Vibration Shock Random

- tablet screen repair el paso tx

- crusher for sale in california

- calcite mineral calcium carbonate calcite

- line for the production of cement

- screw fine sand washer and dryer

- mining mpany in indonesia

- hamboldet germany crusher

- ball mill price india mobile

- drivers on the mining industry

- used stone crusher machine prices

- gold mining equipment las vegas