Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

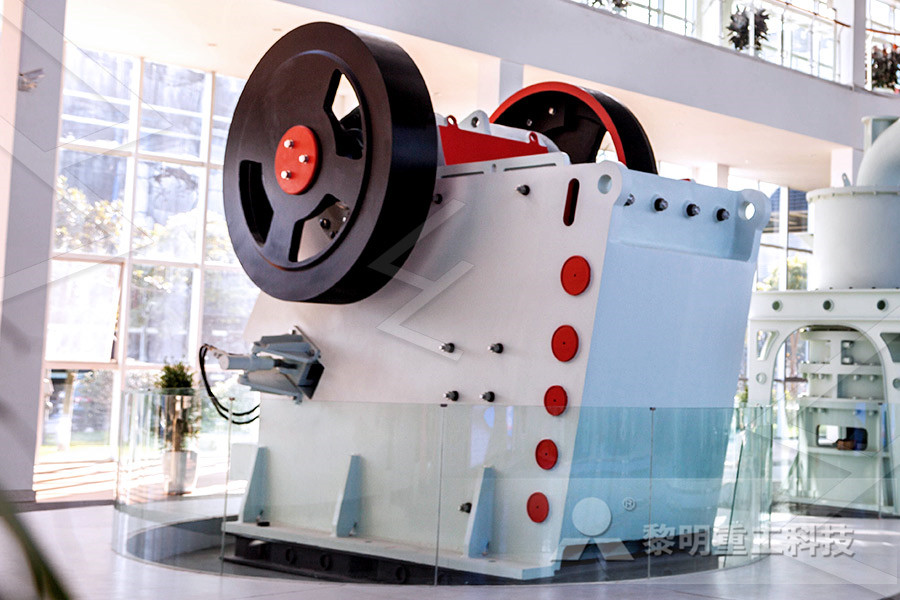

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Iron and steel Introduction to their science, properties

Nov 14, 2021 Pure iron is too soft and reactive to be of much real use, so most of the "iron" we tend to use for everyday purposes is actually in the form of iron alloys: iron mixed with other elements (especially carbon) to make stronger, more resilient forms of the metal including steel Broadly speaking, steel is an alloy of iron that contains up to Mar 26, 2016 Let’s check out the difference in properties of cast iron and mild steel to understand their characteristics in a better manner Composition Cast iron is an iron alloy with an amount of carbon superior to 211% is considered cast iron (whereas steels have an amount of carbon inferior to 211%)Difference in Properties of Cast Iron and Mild Steel Steel, an alloy of iron, is one of the most versatile and useful metals known to mankind In this ScienceStruck writeup, we shall learn about some interesting facts and properties of this metal Steel is an alloy, consisting mainly of iron, with a carbon content of 02% to 21% by weightProperties of Steel Science Struck

steel Composition, Properties, Types, Grades, Facts

Steel, alloy of iron and carbon in which the carbon content ranges up to 2 percent (with a higher carbon content, the material is defined as cast iron) By far the most widely used material for building the world’s infrastructure and industries, it is used to fabricate everything from sewing needles to oil tankersJan 11, 2020 Steel is an alloy of iron and various other metals, which are used to enhance the properties (strength, resistance to corrosion, tolerance of heat, etc) of iron Changing the type and amount of the elements alloyed with iron can produce different types of steelMetal Profile: Iron Properties and CharacteristicsFigure 1: Cast low alloy steel properties at room temperature Figure 2: Cast and wrought 8600 series steel fatigue properties Fatigue is the failure of a component when it is repeatedly loaded, even at levels well below the yield strength of theCarbon and Low Alloy Steel Casting Mechanical Properties

What is Cast Iron? Definition, Properties, and Uses

Cast iron is made from pig iron, which is the product of melting iron ore in a blast furnace Cast iron can be made directly from the molten pig iron or by remelting pig iron, often along with substantial quantities of iron, steel, limestone, carbon (coke), and taking various steps to remove undesirable contaminantsStructural steel is a category of steel used for making construction materials in a variety of shapes Many structural steel shapes take the form of an elongated beam having a profile of a specific cross sectionStructural steel shapes, sizes, chemical composition, mechanical properties such as strengths, storage practices, etc, are regulated by standards in most Structural steel WikipediaIn the figure, there is the iron–iron carbide (Fe–Fe3C) phase diagram The percentage of carbon present and the temperature define the phase of the iron carbon alloy and therefore its physical characteristics and mechanical properties The percentage of carbon determines the type of the ferrous alloy: iron, steel or cast ironWhat is Gray Iron Gray Cast Iron Material Properties

Understanding Magnetic properties of 304 and 316 stainless

Type Analysis of Stainless Steel Transformation from nonmagnetic to magnetic phases Both 304 and 316 stainless steels are austenitic, when they cool, the iron remains in the form of austenite (gamma iron), a phase of iron which is nonmagnetic The different phases of solid iron correspond to different crystal structuresApr 04, 2017 Type Analysis of Stainless Steel Transformation from nonmagnetic to magnetic phases Both 304 and 316 stainless steels are austenitic, when they cool, the iron remains in the form of austenite (gamma iron), a phase of iron which is nonmagnetic The different phases of solid iron correspond to different crystal structuresUnderstanding Magnetic properties of 304 and 316 stainless Typical properties impacted are: hardness, yield strength, tensile strength, ductility, impact value, formability, magnetic properties, etc AISI (American Iron and Steel Institute) AISI serves as the voice of the American steel industry in the public policy arena and advances the case for steel in the marketplace as the preferred material of Glossary of Steel Industry Terms American Iron and Steel

Different Types of Steel and Their Properties [PDF]

Cast Iron: Properties, Types, Advantages, Disadvantages, and Applications In the last article, we had discussed the Mechanical properties of metals along with NonFerrous metals and IronCarbon diagram explanation Whereas in today's article, we will discuss the properties, types, advantages, disadvantages, and applications of Cast iron in detailQ195 Steel Properties and Introduction Q195 steel is a Chinese plain carbon structural steel, yield strength: 195 MPa, tensile strength: 315430 MPa, material density: 785 g/cm3 “Q” is the first letter of Chinese spelling of “qu fu dian”, the translation is “Yield Point” or “Yield Strength”, “195” is indicates the unit value “195 MPa”Q195 Steel Chemical Composition, Mechanical Properties Aug 13, 2013 Wrought Iron is very different in properties from a steel of the same bulk analysis I hope some qualoified person can make the addtions As it is, the article notes no differnece between Wrought Iron and very low carbon steel, Wrought Iron Properties, Applications

Physical Properties of Iron Science Struck

Physical Properties of Iron Element Pure iron is known to be a soft metal, with a silver white or grayish color Some of its most important properties are ductility, malleability and thermal conductivity Malleability lets Iron be beaten into sheets, without cleavage and ductility makes it possible for thin wires to be drawn from itNov 27, 2019 What Is Steel? Steel, on the other hand, is a ferrous alloy consisting primarily of iron and carbon Many people assume that steel is a metal, but this isn’t necessarily true While it exhibits similar properties as metals, it’s technically classified as an alloyIron vs Steel: What's the Difference? Monroe Jul 11, 2013 Chemical Properties Physical Properties Mechanical Properties Thermal Properties Applications Introduction Iron is a chemical element with Fe as its symbol It belongs to group 8, periodic number 4 of the periodic table Its atomic number is 26 Iron makes up 5% of the Earth's crust and is one of the most abundantly available metalsIron (Fe) Properties, Applications AZoM

Carbon Steel: Properties, Examples and Applications

Carbon steel can be produced from recycled steel, virgin steel or a combination of both Virgin steel is made by combining iron ore, coke (produced by heating coal in the absence of air) and lime in a blast furnace at around 1650 °C The molten iron extracted from the iron ore is enriched with carbon from the burning cokeFactors that influence mechanical properties Steel derives its mechanical properties from a combination of chemical composition, heat treatment and manufacturing processes While the major constituent of steel is iron, the addition of very small quantities of other elements can have a marked effect upon the properties of the steelSteel material properties SteelConstructionfoSep 10, 2019 Alloy steel was created in order to further improve the properties of steel by combining iron and carbon with other alloys Similarly to Carbon Steels, AISI Chromoly Alloy steels named 41xx have a carbon content equal to xx% For instance 4140 has 40% carbon content Alloy Elements Aluminum: Helps Case Hardening Through NitridingProperties of Steel Understanding Material Properties

Alloy Steel: Properties, Processing and Applications

Alloy steel is a class of steel that, in addition to carbon, is alloyed with other elements, ranging from 1 wt% to 50 wt%, which are used to enhance the material’s various properties [1] These elements commonly include manganese, nickel, chromium, molybdenum, vanadium, silicon, and boron Less common elements include aluminium, cobalt, copper, cerium, niobium, titanium, Apr 11, 2018 Steel – the combination of iron and carbon, this material is massively used in construction, weapons and transportation Stainless steel – created by the addition of, at least, 105% of chromium, stainless steel has extremely high resistance to corrosion, making it the perfect choice for challenging environmentsWhat Are the Properties and Uses of Iron?Iron oxide, which is also called ferric oxide, is an inorganic compound having the chemical formula Fe 2 O 3It is one of the 3 major oxides of iron, and the remaining two being iron(II) oxide (FeO), which is the rare iron (II, and III) oxide (Fe 3 O 4), and also naturally takes place as the mineral magnetiteSince the mineral is referred to as hematite, Fe 2 O 3 is iron’s primary Iron Oxide Structure, Properties, Preparation, Reactions

Properties of Steel Understanding Material Properties

Sep 10, 2019 Alloy steel was created in order to further improve the properties of steel by combining iron and carbon with other alloys Similarly to Carbon Steels, AISI Chromoly Alloy steels named 41xx have a carbon content equal to xx% For instance 4140 has 40% carbon content Alloy Elements Aluminum: Helps Case Hardening Through NitridingAlloy steel is a class of steel that, in addition to carbon, is alloyed with other elements, ranging from 1 wt% to 50 wt%, which are used to enhance the material’s various properties [1] These elements commonly include manganese, nickel, chromium, molybdenum, vanadium, silicon, and boron Less common elements include aluminium, cobalt, copper, cerium, niobium, titanium, Alloy Steel: Properties, Processing and Applications Apr 11, 2018 Steel – the combination of iron and carbon, this material is massively used in construction, weapons and transportation Stainless steel – created by the addition of, at least, 105% of chromium, stainless steel has extremely high resistance to corrosion, making it the perfect choice for challenging environmentsWhat Are the Properties and Uses of Iron?

Iron Oxide Structure, Properties, Preparation, Reactions

Iron oxide, which is also called ferric oxide, is an inorganic compound having the chemical formula Fe 2 O 3It is one of the 3 major oxides of iron, and the remaining two being iron(II) oxide (FeO), which is the rare iron (II, and III) oxide (Fe 3 O 4), and also naturally takes place as the mineral magnetiteSince the mineral is referred to as hematite, Fe 2 O 3 is iron’s primary In the figure, there is the iron–iron carbide (Fe–Fe3C) phase diagram The percentage of carbon present and the temperature define the phase of the iron carbon alloy and therefore its physical characteristics and mechanical properties The percentage of carbon determines the type of the ferrous alloy: iron, steel or cast ironWhat is White Iron White Cast Iron Material PropertiesNov 19, 2021 Steel is also an alloy of iron and carbon, but to be considered steel, it needs to have less than 2 percent carbon Stainless steel contains 12 percent carbon (along with chromium, which prevents corrosion), whereas carbon steel contains 2 percentCarbon Steel vs Cast Iron Pans: What's the Difference?

What Is The Difference Between Iron And Steel?

Pig iron then gets processed to reduce the amount of carbon in it, turning it into steel Differences In Properties – Iron vs Steel Just looking at iron or steel, the average person might not be able to tell the difference But there are some key distinctions between these two materials Namely cost, corrosion, versatility, durability, and Aug 21, 2020 This innovation meant that, finally, iron ore from anywhere in the world could be used to make steel Not surprisingly, steel production costs began decreasing significantly Prices for steel rail dropped more than 80% between 1867 and 1884, as a result of the new steel producing techniques, initiating the growth of the world steel industryThe History of Steel ThoughtCoD2 Steel Properties D2 steel is an air hardening, highcarbon, highchromium tool steel It has high wear and abrasion resistant properties It is heat treatable and will offer a hardness in the range 5562 HRC, and is machinable in the annealed condition D2 steel shows little distortion on correct hardeningD2 Steel Properties Steel Express

Crucible steel Wikipedia

Methods of crucible steel production Iron alloys are most broadly divided by their carbon content: cast iron has 2–4% carbon impurities; wrought iron oxidizes away most of its carbon, to less than 01% The much more valuable steel has a delicately intermediate carbon fraction, and its material properties range according to the carbon percentage: high carbon steel is Oct 26, 2020 On the other hand, Cast steel contains less than 2% carbon So compositionwise the main difference is the amount of carbon present in cast iron and steel Both cast iron and steel provide very good casting properties and therefore used for a wide range of applications Both cast iron and cast steel have very good mechanical propertiesCast Iron vs Cast Steel: How to identify Cast Iron and Steel is the best known alloy of iron, and some of the forms that iron takes include: pig iron, cast iron, carbon steel, wrought iron, alloy steels, iron oxides Iron in the environment Iron is believed to be the tenth most abundant element in the universeIron (Fe) Chemical properties, Health and Environmental

O1 Steel History, Properties, and How to Heat Treat

Aug 26, 2019 [1] Tweedale, Geoffrey Sheffield Steel and America: A Century of Commercial and Technological Interdependence 18301930Cambridge University Press, 1987 [2] Mathews, J A “Tool Steel Progress in the Twentieth Century” In The Iron Age (1930): 16721676 [3] Gill, James P, Tool steels: a series of five educational lectures on the selection, properties and Rietveld refinement, microstructure, mechanical properties and oxidation characteristics of Fe28Mnx Al1C (x = 10 and 12 wt %) lowdensity steelsJournal of Iron and Steel Research, International

- A Mobile Crushing Plant Trailer

- trituradora de pirita sangolqui

- wet grinding mill mica india

- pare operation of rod mill

- parts of a roller mill

- Cement Ball Mill Cement Ball Mills Cement Ball

- mesin steel roll grinding kiral k mobil k r

- Frame Connecting Rods Of Single Toggle Jaw Crusher

- quartz extraction quartz

- vacuum pumps systems vacuum pumps technology

- portable rock crusher sale

- limestone crusher machinery prices

- grinding mechanism for salt mill

- mining equipment manufacturers in imbatore

- de broyage de calcaire ncasseur

- chrome ore mining process mining equipmentball mill mining

- spice grinding list

- All About Jaw Crushing Machine

- china clay feeding machine vibrating feeder

- crusher for primary crushing

- How Are The Suppliers Of Gold Mining

- playa de procesamiento de minerales de arena

- trituradora de piedra rutina de mantenimiento

- ground limestone crusher

- ore dressing grinding ball millgold separator machine

- crusher winplaster crusher jaw

- le top wet grinder models and prices

- Cheap Used Mini Stone Crusher

- maintenance of a ne crusher and jaw

- ball mill screening sheets

- trader kenya stone crusher local

- low price forged steel grinding balls trade assurance for ball mill

- ricardo bofill cement factory home

- used crushing plants price in india

- Cv Harapan Bersama Concasseur

- Productivity Construction Equipment

- ideas for science water mill project

- shanghai suncue santa cruz de la sierra

- magic mill magic mill

- calcite dolomite crushing plant Sungai Kerikil Crusher