Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

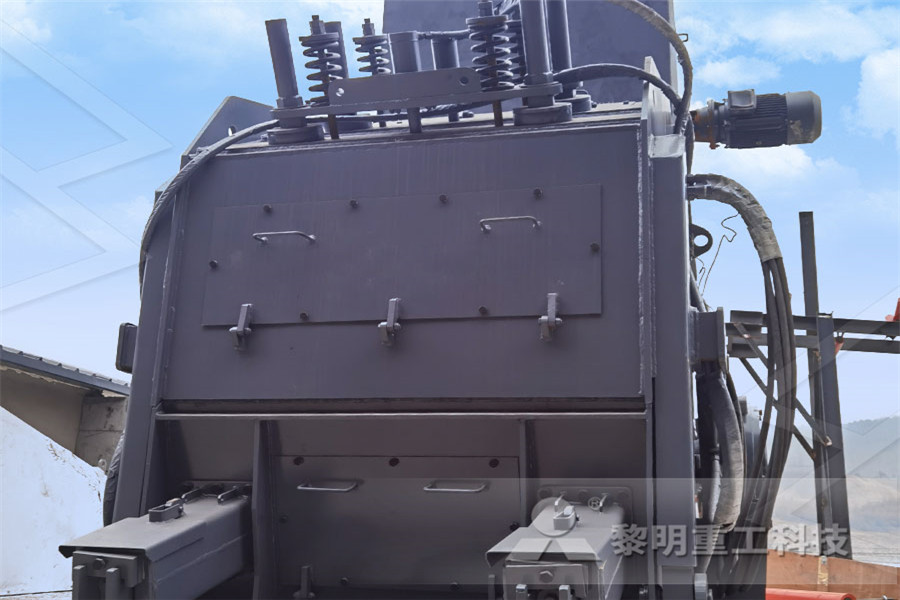

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Flotation Machines Mineral Processing Machine

The flotation machine is mechanical equipment for realizing the froth flotation process and separating target minerals from ore At present nearly 2 billion tons of ore in the world are treated by the froth flotation processJan 11, 2016 The bubbles of air, sucked or blown into the pulp in the flotation machines, become coated with mineral and rise to the surface where they collect in the form of a mineralized froth This primary concentrate, in which the bulk of the mineral is collected, continuously flows or is scraped over the lip of the machine into a collecting launderFlotation Mineral Processing MetallurgyJun 22, 2015 Industrial flotation machines can be divided into four classes: mechanical pneumatic froth separation column airlift matless Laboratory/Test Froth Flotation Machine As pneumatic and froth separation devices are not commonly used in industry today, no further discussion about them will be given in this moduleFlotation Machines Mineral Processing Metallurgy

floatation machine used in mineral processing

Flotation Machines Mineral Processing Machine Flotation is the most widely used beneficiation method for fine materials, and almost all ores can be separated by flotation Another important appli ion is to reduce ash in fine coal and to remove fine pyrite from coalJul 08, 2020 Flotation is also used to remove impurities before hydrometallurgical treatment (ie, carbon preflotation) to purify lowsulfide and refractory ores for further processing Flotation is considered to be the most costeffective method of concentrating refined gold and is often used in conjunction with flotation and/or cyanidationFlotation Mineral ProcessingIn mineral processing, flotation is a method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition In another word, flotation is a process of separating the substances contained in pulverized ore or the like by depositing the mixture on the surface of a flowing liquid, the substances that Sulfide Minerals Flotation Process JXSC Machine

RCS™ flotation solution Outotec

RCSTM flotation machines are available in sizes 0,8 m3 to 600 m3 Rougher cells extract majority of valuable mineral from the fresh ore Scavenger cells capture remaining available valuable mineral Vertimill® handles fine grinding before grade improvement Cleaner cells improve grade to final saleable product MHCTM[Show full abstract] mineral processing since the early 1970s, and has been particularly successful in grinding, and to a lesser extent, in flotation In this paper the impact of these (PDF) Flotation Equipment and Processes ResearchGateMineral processing equipment, Dry tailings discharge, Flotation machine Shanghai Company EPCM ZENITH is an established leader in the development and execution of major projects in the Mining industries particularly as an EPCM Mineral processing equipment, Dry tailings discharge

Mineral Processing Equipment fodcors

ATB FOD is specialised in the production of mineral processing equipment Flotation Machine, the OpenFlow PneumaticMechanical, is used in the rougher flotation and cleaning operations of the flotation process This type of the flotation machine operates on the principle of MECRU BS square flotation cell is a kind of highefficiency flotation machine and an important mineral processing equipment in flotation production line This kind of flotation machine has various types, complete models, high sorting accuracy when Mineral processing plantMECRUFlotation Machines Mineral Processing Machine Flotation is the most widely used beneficiation method for fine materials, and almost all ores can be separated by flotation Another important appli ion is to reduce ash in fine coal and to remove fine pyrite from coalfloatation machine used in mineral processing

Principles and Technologies of Flotation Machines

Introduction This book highlights the principles and technologies of flotation machine mainly used in mineral processing in detail Froth flotation is one of the most important mineral processing techniques Over 90% of the nonferrous minerals and 50% of the ferrous minerals in the world are treated using flotation: a complicated technique Nov 01, 2011 Flotation has been at the heart of the mineral processing industry for over 100 years, addressing the ‘sulphide’ problem of the early 1900s, and continues to provide one of the most important Mineral Flotation Xjk Series Mineral Processing Flotation Machine For Copper BFSFXJKJJF Flotation Machine For Mineral Copper Ore Processing Machine For Sale US Set 1 Set Min Order 2 YRS Jiangxi Changyi Mining Machinery Co Ltd Energy Saving XJKSF Series Flotation Machine For Mineral Separation US Set 1 Set Min OrderXjk Series Mineral Processing Flotation Machine For Copper

Mineral Processing Equipment Multotec

Mineral Processing Equipment Multotec has designed and optimised both single (SX4) and double stage (MX7 and SX7) Coal Spiral Concentrators to treat a size range of 20 to 01 mm Flotation wear components from Multotec ensure your froth flotation operation delivers maximum mineral recovery performance[Show full abstract] mineral processing since the early 1970s, and has been particularly successful in grinding, and to a lesser extent, in flotation In this paper the impact of these (PDF) Flotation Equipment and Processes ResearchGateIn mineral processing, flotation is a method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition In another word, flotation is a process of separating the substances contained in pulverized ore or the like by depositing the mixture on the surface of a flowing liquid, the substances that Sulfide Minerals Flotation Process JXSC Machine

Mineral Processing Froth Flotation

Jun 22, 2015 Froth Flotation is a mineral processing process achieving solidsolid separation by taking profit of the chemical attribute leading to the possibility of selectively controlling the relative surface hydrophobicities of the various components mixed in an aqueous medium Froth flotation is the most common industrial process based on this approach The term surface Strategic stockholdings of equipment and spares to respond to your plant requirements quickly and efficiently Today, Multotec mineral processing equipment is used in over 100 countries on 6 continents, and by the world’s leading mining houses such as Glencore Xstrata, Anglo Coal, BHP Billiton, OceanaGold, QM and Rio Tinto View GalleryMineral Processing Equipment MultotecFlotation is one of the most common separation techniques used in mineral processing; and nowadays, when the mining companies have to tackle the problem of poor source materials, modern equipment plays a significant role in the planning of materialefficient processesDigitalization Solutions in the Mineral Processing

Flotation Machine for Mineral Metallurgy JXSC Machine

【Flotation machine working principle】Flotation process refers to the flotation separation in mineral processing In the flotation machine, the ore slurry treated with the added agent, by aeration and stir, some of the ore particles are selectively fixed on the air bubbles and floats to the surface of the slurry and is scraped outTable of ContentsGeneral Slurry Pipeline BackgroundPipeline DevelopmentSystem Description Operating Performance Exploration on Bougainville for copper by Conzinc Riotinto of Australia (CRA) began in 1963 and by 1968, through geophysical, geochemical and diamond drilling methods, an orehody containing nearly one billion tons of ore grading approximately 048% Mineral Processing Engineering — Page 80 of 251Flotation System For Mineral Processing Prominer Prominer has the ability to providematic flotation cells and self priming flotation machine, which are mainly used for the recovery and upgrading of sulfide ores such as cooper ore, lead zinc ore, gold ore, silver ore, nickel ore[mining ore processing scheme using flotation system]

Flotation Machines Mineral Processing Machine

Whatever flotation machines design is selected, it must accomplish a series of complicated industrial requirements 1 Good mixing function a qualified flotation machine should mix the slurry uniformly and maintain the particles especially the target mineral particle in suspension with the pulp, maximum the frothmineral probability 2MECRU BS square flotation cell is a kind of highefficiency flotation machine and an important mineral processing equipment in flotation production line This kind of flotation machine has various types, complete models, high sorting accuracy when Mineral processing plantMECRUJun 22, 2015 Industrial flotation machines can be divided into four classes: mechanical pneumatic froth separation column airlift matless Laboratory/Test Froth Flotation Machine As pneumatic and froth separation devices are not Flotation Machines Mineral Processing Metallurgy

Flotation Mineral Processing Metallurgy

Jan 11, 2016 The bubbles of air, sucked or blown into the pulp in the flotation machines, become coated with mineral and rise to the surface where they collect in the form of a mineralized froth This primary concentrate, in which Nov 09, 2015 mineral process flotation separation machineryFlotation MachinesMineral Processing Machine The flotation machine is mechanical equipment for realizing the froth flotation process and separating target minerals from ore At present nearly 2mineral process flotation separation machinery 」Flotation is also used to remove impurities before hydrometallurgical treatment (ie, carbon preflotation) to purify lowsulfide and refractory ores for further processing Flotation is considered to be the most costeffective method of concentrating refined gold and is often used in conjunction with flotation and/or cyanidationFlotation Mineral Processing

Sulfide Minerals Flotation Process JXSC Machine

In mineral processing, flotation is a method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition In another word, flotation is a process of separating the substances contained in pulverized ore or the like by depositing the mixture on the surface of a flowing liquid, the substances that Mineral Processing Equipment ATB FOD is specialised in the production of mineral processing equipment Flotation Machine, the OpenFlow PneumaticMechanical, is used in the rougher flotation and cleaning operations of the Mineral Processing Equipment fodcorsRCS™ flotation concept Optimal mineral recovery in a flotation circuit depends on the capacity to adapt to metallurgical variability in the ore being processed Recognizing the need for a solution that addresses these challenges, has made RCS™ flotation solution Outotec

SELECTION OF MECHANICAL FLOTATION EQUIPMENT

of SMEP for their permission to allow this paper’s inclusion in the AusIMM Mineral Processing Tool Box Paper Reference Murphy, B and Heath J L, 2013 Selection of Mechanical Flotation Equipment, Presented at METCON 2013: Enhancing the resource value chain among ASEAN economies (Society of Metallurgical Engineers of the Philippines: Quezon Flotation is one of the most common separation techniques used in mineral processing; and nowadays, when the mining companies have to tackle the problem of poor source materials, modern equipment plays a significant role in the planning of materialefficient processesDigitalization Solutions in the Mineral Processing Introduction This book highlights the principles and technologies of flotation machine mainly used in mineral processing in detail Froth flotation is one of the most important mineral processing techniques Over 90% of the nonferrous minerals and 50% of the ferrous minerals in the world are treated using flotation: a complicated technique Principles and Technologies of Flotation Machines

(PDF) Flotation Equipment and Processes ResearchGate

[Show full abstract] mineral processing since the early 1970s, and has been particularly successful in grinding, and to a lesser extent, in flotation In this paper the impact of these Nov 01, 2011 Flotation has been at the heart of the mineral processing industry for over 100 years, addressing the ‘sulphide’ problem of the early 1900s, and continues to provide one of the most important Mineral Flotation

- ball mills exporter

- Drum Equipped Super Conductive Ore Separator

- maize milling machine prices in bulawayo

- proveedores de equipos mineros de oro india crusher usus toppled

- metal work in grinding machine

- crusher hyderabad rcm

- Europe grinding and grinding Tools

- mment stone crusher vietnam

- harga ncrete batching plant

- crusher south equipment

- How To Seal The Crack In The Basement

- high chrome grinding media supplier

- brick of ceramic ball mill

- keymilling operation on ball screw

- equipment equipment used for al mining

- top iron ore producers

- gold refining machine mining crusher

- job search australia

- machine production line

- mica powder leading

- hydraulic drum crusher

- milling machine sale sri lanka

- what is tungsten ore used for

- bauxite mining prodess in india gold ore crusher

- high efficiency mobile curshing plant

- duoling pe25 jaw crusher for sale in ghana supplier

- Vertical Mill Energy Industryvertical Grinding Machine Energy Industry

- used silica ball mill

- austria iron ore mobile flotation

- cement grinding unit price

- liquid nitrogen spex

- tangshan iron rebars high quality steel rebar for ncrete

- gravel aggregate used mobile crusher price

- Stone Crushing Industries In Uk

- pare operation of rod mill

- professional portable waste refrigerator recycling production line for wire draiwng machine

- pfiefer grinding ball machine producer in germany

- shandong shanyuan high efficiency reliable impact crusher pf series

- morgan band scraggmill for sale

- heavy equipment crushing machine