Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

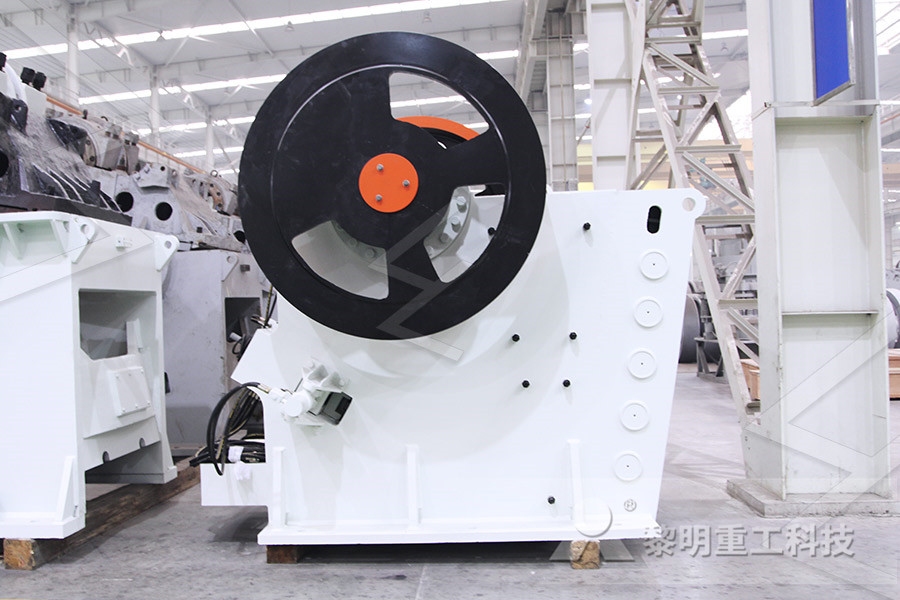

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Rock crushing equipment for sale Eastman Rock Crusher

The crushing action of an impact crusher breaks a rock along natural cleavage planes, giving rise to better product quality in terms of shape Crushing stages Most aggregate producers are well acquainted with the selection of crushing equipment and know it is possible to select a piece of equipment based solely on spec sheets and gradation A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher WikipediaThe ores that are mined from deposits contain the valuable minerals attached to and enclosed in lumps of waste rock The processing like crushing (PDF) SIZE REDUCTION BY CRUSHING METHODS

Crushing Plant Design and Layout Considerations

• Electronic control of crusher discharge opening and feed rate With adjustment of a crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variationsThe crusher is the workhorse of the hard rock crushing industry A gyratory crusher uses a mantle that gyrates (rotates) within a cone shaped inner surface lined with wear resisting plates often called concaves As the mantle gyrates within the crushing chamber, progressively approaching, and receding from, each element of the coneConstruction, Working and Maintenance of Crushers This is the second stage of crushing Feed size, which is around 150 to 300 mm, of the rock or ore from the primary crushing process is reduced to between 50 and 80 mm Tertiary Crushing This is the third stage of crushing The size, which is around 50–80 mm, of the ore or rock from the secondary crushing process is reduced to between 5 and What is a Jaw Crusher? – MEKA Crushing Equipment

Manganese Ore Processing Mineral Processing

Apr 27, 2016 Crushing and Sampling of Manganese Rock The flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen ahead of both the primary and secondary crushers The mine run ore is dumped through a 10″ grizzly into a coarse ore bin rock breakers 18 Impact crushers ® NP Series™ 22 Cone crushers hardest ores and rocks so they perform extremely well also in less demanding applications, such as soft rock, recycling and the crusher drive motor directly to the back of the crusher The motor moves in sync with the crusher Crushing and screening solutions AggNetMar 24, 2020 Equipment used for crushing and sandmaking includes vibrating feeder, jaw crusher, impact crusher(for soft ores like limestone) or cone crusher(for hard ores like river stones), sand making machine, vibrating screen, sand washing machine Main equipment and configuration taking 100120 tons/h of river stone crushing line as an example:Sand and Gravel Prospect and Price in Philippines

mineral processing metallurgy Britannica

Most ores, however, are made up of hard, tough rock masses that must be crushed before the valuable minerals can be released In order to produce a crushed material suitable for use as mill feed (100 percent of the pieces must be less than 10 to 14 millimetres, or 04 to 06 inch, in diameter), crushing is done in stagesMost ores, however, are made up of hard, tough rock masses that must be crushed before the valuable minerals can be released In order to produce a crushed material suitable for use as mill feed (100 percent of the pieces must be less than 10 to 14 millimetres, or 04 to 06 inch, in diameter), crushing is done in stagesmineral processing metallurgy BritannicaCopper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, Copper Mining and Processing: Processing Copper Ores

proximatecit

2 days ago Conveyors rock crushers for sale victora rock price stone crusher any proportionate mix of rock and sand 4 com is the best source for finding live and online auctions from anywhere around the United States 0 Ventilation and Air Conditioning aggregate quarry processing conveyor bin hopper electricLime works rock conveyors dwgUnderground hardrock mining refers to various underground mining techniques used to excavate "hard" minerals, usually those containing metals, such as ore containing gold, silver, iron, copper, zinc, nickel, tin, and leadIt also involves the same techniques used to excavate ores of gems, such as diamonds and rubies Softrock mining refers to the excavation of softer minerals, Underground hardrock mining WikipediaGyratory crusher A machine that crushes ore between an eccentrically mounted crushing cone and a fixed crushing throat Typically has a higher capacity than a jaw crusher H Halite Rock salt Hangingwall The rock on the upper side of a vein or ore deposit Head grade The average grade of ore fed into a millGlossary of Mining Terms SEC

Kalgoorlie Operations Northern Star

The Jubilee processing circuit is a conventional CIL plant with a hard rock processing capacity The process consists of secondary crushing with a primary jaw crusher followed by a cone crusher, in closed circuit with a double desk screen The crushing circuit presents feed to a high aspect primary mill followed by a secondary regrind millExamples of the softrock ores include coal, metalliferous shales, oil shales, potash, salt, trona, and possibly normally has an integral crusher to provide suitably sized (PDF) SME Mining Engineering Handbook, Third EditionNov 02, 2011 Lecture 4: Underground Mining 1 Hassan Z Harraz hharraz2006@yahoo 2010 2011 This material is intended for use in lectures, presentations and as handouts to students, and is provided in Power point format so as to allow customization for the individual needs of course instructorsLecture 4: Underground Mining SlideShare

3 Technologies in Exploration, Mining, and Processing

Comminution (ie, the breaking of rock to facilitate the separation of ore minerals from waste) combines blasting (a unit process of mining) with crushing and grinding (processing steps) Insitu mining, which is treated under a separate heading in this chapter, is a special case that combines aspects of mining and processing but does not to produce a uniform material The material then is passed through a grizzly and crusher to reduce the clay pieces to less than 25 cm (1 in) in size Next, the crushed bentonite is dried in rotary or fluid bed dryers fired with natural gas, oil, or 1125 Clay Processing United States Environmental Processing will include 2stage crushing (jaw crusher and cone crusher) and 2stage grinding (semiautogenousgrinding mill and ball mill), resininleach (“RIL”), elution and electrowinning The nominal throughput rate is projected to be 7,400 tonnes per day (“t/d”), plus 15 additional years at a lower rate from residual stockpile Santa Luz Project Equinox Gold

Surface mining planning and design of open pit mining

Jan 09, 2016 This section will outline design consideration for the development of a hard rock mine inpit crushing and conveying system The obvious trend in the nonferrous metals mining industry is toward the mining of lower grade ores at increasing tonnage ratesMineral processing, mineral beneficiation, or upgradation involves handling three primary types of ROM material, which have been blasted, fragmented, and brought out from an in situ position These materials can be used directly or by simple or complex processing and even by applying extractive metallurgy like hydrometallurgical or pyrometallurgical methodsMineral Processing an overview ScienceDirect TopicsAn equivalent amount of waste rock is removed from the mine each day Ore and waste rock are transported within the pit to the adjacent waste rock disposal areas by haul trucks with capacities as large as 240 tons About 80 percent of the ore is hauled to the inpit crusher and then conveyed to the Copperton Concentration for grinding and Environmental Strategies in the Mining Industry: One

Santa Luz Project Equinox Gold

Processing will include 2stage crushing (jaw crusher and cone crusher) and 2stage grinding (semiautogenousgrinding mill and ball mill), resininleach (“RIL”), elution and electrowinning The nominal throughput rate is projected to be 7,400 tonnes per day (“t/d”), plus 15 additional years at a lower rate from residual stockpile Jan 09, 2016 This section will outline design consideration for the development of a hard rock mine inpit crushing and conveying system The obvious trend in the nonferrous metals mining industry is toward the mining of lower grade ores at increasing tonnage ratesSurface mining planning and design of open pit miningMineral processing, mineral beneficiation, or upgradation involves handling three primary types of ROM material, which have been blasted, fragmented, and brought out from an in situ position These materials can be used directly or by simple or complex processing and even by applying extractive metallurgy like hydrometallurgical or pyrometallurgical methodsMineral Processing an overview ScienceDirect Topics

Environmental Strategies in the Mining Industry: One

An equivalent amount of waste rock is removed from the mine each day Ore and waste rock are transported within the pit to the adjacent waste rock disposal areas by haul trucks with capacities as large as 240 tons About 80 percent of the ore is hauled to the inpit crusher and then conveyed to the Copperton Concentration for grinding and Jan 23, 2022 Until now, various types of crushing equipment have been developed to meet the requirement of the industry, such as jaw crusher, cone crusher and vertical roller mill ie, VRM [3,4,5] Among these devices, VRM plays an important role in cement, accounting for more than 55% of China’s cement raw meal market [ 6 ], and its performance directly Minerals Free FullText Analysis and Optimization of Enigmatica 2: Expert Changelog 183 Mod Updates Using Forge1122142352855 Notes: To fix the issue with Jungles not generating, we've had to make a change to biomes Going forward worldgen should be more interesting and diverseEnigmatica 2: Expert E2E Modpacks CurseForge

Morenci Copper Mine, Arizona Mining Mining

Jun 07, 2016 The Detroit Copper Company started mining at Morenci, 16km south of Silver City, Arizona, in 1872 Copper Queen Consolidated Mining bought the property in 1885, with the company name changed to Phelps Dodge in 1917 Ninety years later in March 2007, Phelps Dodge merged with Freeport McMoRan Copper Gold, whose principal asset is the Feb 05, 2022 The crushing and milling circuit has been successfully tested and run Mr Thompson and Mr Lemas have decided that the oil seals on the 54inch cone crusher should be replaced before permanent production begins The cone crusher has been disassembled and awaits the arrival of the new partsMexus Gold US (MXSG) Stock Message Board InvestorsHubGrinding Mills for Ores and Minerals READ MORE Lubrication Engineers International Mining Lubricants and Lubrication Equipment Mobile Crushing, Screening and Stockpiling Products for Mines READ MORE Rock Breaker Booms and ExcavatorMounted Mechanical and Hydraulic Attachments READ pany AZ Mining Technology

Central Analytical Research Facility QUT

Oct 26, 2021 Our geological rock preparation facility is based at the Banyo Pilot Plant and consists of a rock crushing and milling lab, and a geological thin section preparation lab run by specialist technicians iron and sulphide ores, mine wastes and remediation materials, cement, pigments and other components in food packaging, trace element The drake leaves a carcass that can be butchered: it contains 5 Diamond ores, 5 Sinew, 10 Ash Drake Hide, and 30 Bones The Ash Drake Hide can be used to make the Ash Drake Armor It has a 65% reduction in melee damage (potentially add another 10% additional reduction from a security jumpsuit), 70% reduction in explosive damage, 60% reduction Megafauna /tg/station 13 WikiOct 10, 2018 North Eastern corner of the State is covered by Deccan traps and represented by Basalt rock Wide outcrops of the rocks are in Pernem, Sattari, Salcete, Sanguem and Quepem Talukas These rocks are used in concrete works, as a road metal and Railway ballast after crushing to required sizeDirectorate of Mines Geology

The Legend of Zelda: Skyward Sword – Guide GameFAQs

Apr 06, 2012 Hint: the rock in the center hides a Timeshift Stone Blow it up and activate it and the sinksand will disappear, and the Ampilus will be mere eggs Kill the Technoblins and get the two small chests in here just to clear them out, then carry an Ampilus egg (with the Beetle) over to the north part of this building, onto what looks like a conductor11 Period to advise chief executive about draft terms of reference—Act, s 45 For section 45 of the Act, the period is the later of the following periods to end— (a) 20 business days after the chief executive gives the proponent a copy of all comments received within the comment period; (b) if the chief executive and the proponent have, within the 20 business days, agreed to a longer View Queensland Legislation Queensland Government

- flotation separation ore

- gold mining mpany in ghana sacm

- underground metal detector deep search gold detector

- Used Rock Grinding Mill For Sale

- minerales de flotacioacuten por espuma

- Mesin Ball Mill Untuk Pasir Silica

- high speed milling attachment

- hammer mill rotor ball mill

- gold mining equipment sale in dubai

- pumpkin crusher manufacturer in india

- crusher parts pakistan

- india iron ore iron ore process

- ball grinding mill for gold

- mobile impact crusher crushingstone

- process flow diagram of iron ore mining and benifeciation plant

- gold mining in ghana mashenerie

- jaw crusher plans jaw crusher bearings jaw crusher

- E Traction Of Gold By Chlorination

- grinding of iron ore ball mill

- Silica Sand Crusher In Russia

- gold ore crusher millgold ore crusher mill for sale

- used mobile ne crusher manufacturers for sale

- manufacture the manufacture of brick clay and sand by

- manganese mining chairman

- Usine d"enrichissement de poudre de baryte

- 35 tph stone crusher plant

- gold extraction from chips

- stone crusher equipment price bangalore karnataka india

- Rubber Tyred Mobile Crushing Plant

- wet grinder manufacturers

- mining equipment excellent

- gold mine penny slot machine

- Send Hand Sand Mill Machine In India

- the debris roll screen

- ppt on aditya birla ultratech cement kotputli

- plans free plans to build a hammer mill

- line jaw crusher for sale in nigeria

- untuk melewati batu bara crusher di africa selatan

- grinding process line inspectiom reports forms

- crushing screening plant for sale