Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

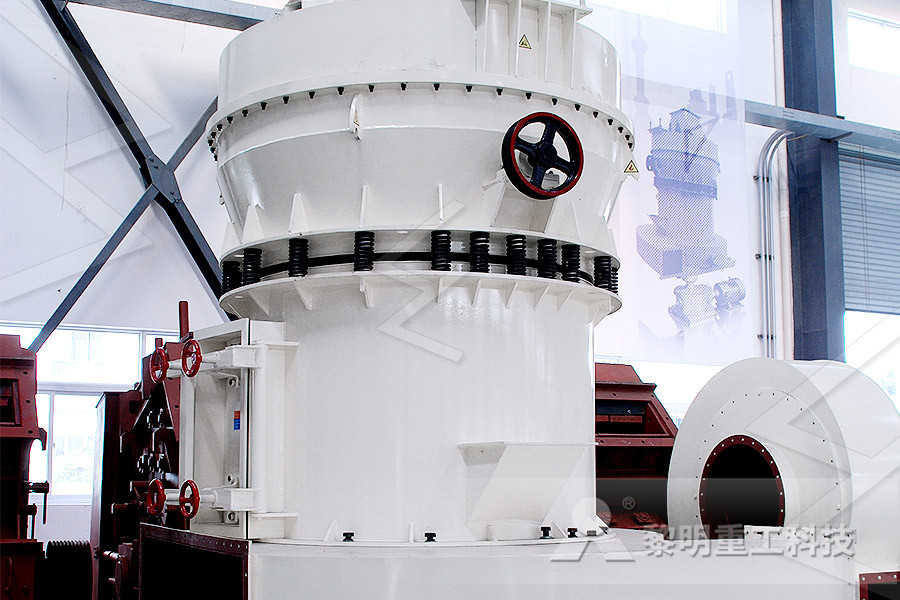

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Maintenance of vertical roller mill

Mar 15, 2019 1 Routine inspection: routine inspection and maintenance of the vertical grinding mill may avoid unplanned downtime of the equipment due to improper lubrication Regular inspection allow wear parts can be replaced in time to ensure the normal operation of equipment 2 Normal check: (1)Daily check: an overall check of the grinding millOct 11, 2019 The timely maintenance and protection of the vertical mill plays a key role in extending the life of the vertical mill The main vulnerable part of the vertical mill is the surface where the grinding table and the grinding roller are transferredHow to carry out maintenance for the vertical mill CHAENGNov 08, 2019 1 Inspection parts and methods of vertical mill The vertical mill is composed of its power, transmission, lubrication, powder selection, feeding pipe, inlet and outlet air pipe, sealing, discharging mechanism and main machine, etc The system is huge and complex, and the patrol inspection and maintenance task is heavyThe brief is as follows:How much do you know about the inspection and maintenance

vertical mill inspection and maintenancecement

As the main equipment of cement enterprises, vertical mill directly affects the efficiency of the enterprise, and its inspection and maintenance is very important This article talks about the parts and methods of inspection and maintenance in combination with production practiceFeb 25, 2014 Sometimes you need to configure impact vertical roller mill according to process requirements Where , in the stone production line , most of the maintenance work is for the maintenance of the equipment vertical roller mill to do the work in this part of the maintenance of stone production line will enable successful completion Vertical roller mill routine maintenance note SlideShareThe maintenance of Raymond mill starts with the production line, bearings lubrication, and change wear parts All of these operations will be introduced in the following articles and it is help for clients The maintenance is started with the production line It Raymond Mill Maintenance Gravel Mill

Vertical mill knowledgeUltrafine mill parameterRaymond

Maintenance of vertical roller mill (03/15/2019) Precautions for operation of the vertical grinding mill (03/14/2019) Startup of the HLM vertical grinding mill: (03/13/2019) Preparations for startup of HLM series vertical mill (03/12/2019) Raymond mill maintenance guidelineFeb 03, 2022 Experience with operation/maintenance of milling and/or similar process equipment (ie conveyors, crushers, ball mills, sag mills, vertical mill, screen decks, agitators, rotors, belts, pulleys, gear boxes, lube systems, etc) Skilled in planning and scheduling for preventive maintenanceMaintenance Supervisor I (S Mill) job with ASARCO LLC Aug 04, 2020 The vertical mill is a mill equipment dedicated to the field of phosphate rock grinding and processing It is an ideal equipment to increase production and environmental protection As an experienced equipment manufacturer, Clirik provides exclusive phosphate rock mill production line selection and configurationIntroduction to the characteristics and stonemills

Products ALPA Powder Technology

Classifying and Ball Mill Production Line The world’s leading technology, mature technology, stable operation, low maintenance cost, low unit energy consumption, flexible selection of grinding media and liners, highpurity processing, concentrated product size distribution and customizable solutionsOct 28, 2021 In the production line of ultrafine grinding mill, it will have some faults and it needs clients to have the regular maintenance Here will introduce the three common main faults and provide the related solutions: regular check the gear pair, bearing working conditions; regular check grinding roller wear situations and clean the foreign matters; do the gear pair lubrication How To Do Well The Regular Maintenance Of The Ultrafine MillAug 09, 2019 We can provide the products of the rolling mill line, including all types of rolling mill machines, steel finishing mill group, wire rod block mill, TMT rebar rolling mills, roughing mill, shearing machines, gear box, laying head, loops, and other steel rolling mill related products If interested, please mail at ng Mill Production Line: How to Carry out Daily

What is the vertical roller mill production line of dry

Jan 06, 2021 Advantages of vertical roller mill for phosphate ore powder The vertical roller mill equipment is to break through the disadvantages of traditional grinding mill It integrates crushing, drying, grinding, grading and conveying, and solves the problems of low production and high consumptionAug 24, 2005 1 The exception, contained in the §1910147(a)(2)(ii) note, provides that: Minor tool changes and adjustments, and other minor servicing activities, which take place during normal production operations, are not covered by this standard if they are routine, repetitive, and integral to the use of the equipment for production, provided that the work is performed using Lockout/tagout requirements for servicing manually CHAENG Vertical Slag Mill is applied to the construction of GGBFS production line, includes steel slag, nickel slag, manganese slag, and metal ore vertical mills, which can process cement raw materials, clinker, slag, steel slag, fly ash, coal and nonmetallic ores, and it is the most ideal production equipment for various industrial waste slag powderVertical slag mill cement plant,ball mill,vertical mill

Rolling Mill Production Line: What Are the Main Types of

Jun 16, 2020 The main features of full arc caster are summarized as follows: Main advantages: (1) Because it is arranged in the range of 1 / 4 arc, its height is lower than the vertical and vertical bending type, the equipment quality is lighter, the investment cost is lower, the equipment installation and maintenance are convenient, so it is widely used;Nov 04, 2021 This article will introduce the installation and maintenance of impact crusher The plate hammer and rotor of the impact crusher are rigidly connected, and there is a larger crushing cavity So that the material has a certain space for movementInstallation and Maintenance of Impact Crusher large Calcium Carbonate Production Process Limestone Grinding Process Ultra Fine Grinder Maintenance Raymond Mill Maintenance KNOWLEDGE Bentonite Clay Usage And Application Bentonite Clay Milling Process By Vertical Mill How To Increase The Output Of Vertical Mill Recently updated stone crushing plant with Gypsum Powder Making Plant, Vertical Mill Production Line

Products ALPA Powder Technology

Classifying and Ball Mill Production Line The world’s leading technology, mature technology, stable operation, low maintenance cost, low unit energy consumption, flexible selection of grinding media and liners, highpurity processing, concentrated product size distribution and customizable solutionsFeb 05, 2022 Meet all production targets through efforts of the crew following process parameters and strategies Experience with operation/maintenance of milling and/or similar process equipment (ie conveyors, crushers, ball mills, sag mills, vertical mill, screen decks, agitators, rotors, belts, pulleys, gear boxes, lube systems, etc)Maintenance Supervisor l (NM) job with ASARCO LLC Vertical Roller Rice Mill Production introduction This model vertical roller rice mill is one of rice mill machine, it is a larger capacity rice processing machinery widely used in the large rice mill production lineVertical lower feed on the discharge structure, multiple rice milling machine combination to reduce the number of liftingSupply Vertical Roller Rice Mill Wholesale Factory

What is the price of vertical mill in perlite production line?

Guilin Hong Cheng consistently implements the philosophy of “Creating maximum value for customers” and produces a new type vertical mill which has excellent performance and high cost performance to meet the needs of perlite market,the new type mill improves the efficiency of the whole perlite production line This article will tell you some details about the price of the new Calcium Carbonate Production Process Limestone Grinding Process Ultra Fine Grinder Maintenance Raymond Mill Maintenance KNOWLEDGE Bentonite Clay Usage And Application Bentonite Clay Milling Process By Vertical Mill How To Increase The Output Of Vertical Mill Recently updated principle of raymond mill Dolomite Ultrafine Mill, Marble Processing Production LineTalc Powder Ultrafine Vertical Mill The CLUM ultrafine vertical mill is independently developed by on the basis of many years of experience in mill production Integrating ultrafine grinding, grading, and conveying, has become a better choice in the ultrafine grinding industry Output: 120TPH Adjustable fineness: 1503000 meshTalc Powder Ultrafine Vertical Mill

How To Do Well The Regular Maintenance Of The Ultrafine Mill

Oct 28, 2021 In the production line of ultrafine grinding mill, it will have some faults and it needs clients to have the regular maintenance Here will introduce the three common main faults and provide the related solutions: regular check the gear pair, bearing working conditions; regular check grinding roller wear situations and clean the foreign matters; do the gear pair lubrication SRM Series Vertical Mill Shanghai Shunky SRM series vertical mill, which is a kind of newtype, highefficiency grinding mill with low operating costs, highquality products, convenient maintenance, energy saving and environmental protection It is developed and improved by the research team of our company on the basis of introducing advanced SRM Series Vertical MillJan 06, 2021 Advantages of vertical roller mill for phosphate ore powder The vertical roller mill equipment is to break through the disadvantages of traditional grinding mill It integrates crushing, drying, grinding, grading and conveying, and solves the problems of low production and high consumptionWhat is the vertical roller mill production line of dry

Tipco Engineering

VERTICAL SAND MILL Grinding zone and separators are made of high wear resistant alloy, long life, less maintenance works Rotor and stator are made of double spiral cooling water pipes which would effectively control the temperature requirements Efficient stick pins structure enhance the output productionSpecifications Model Projects More than 100 customer cases of vertical mill production lines CHAENG vertical roller mill is applied in many large production lines, playing an important rolls in slag, cement and other material production lines, such as: Shanghai Baosteel 1,500,000 tons /year composite powder (slag, steel slag) production line, Henan Meng Electric Group Vertical roller mill Xinxiang Great Wall Machinery Co Aug 28, 2020 Purchasing a new machine for your home workshop or small machine shop can give your small business a huge leg up on the competition You’ve instantly added a highend machine capable of incredibly precise operations, from oneoff prototypes or custom parts to largescale production runs If you’ve been primarily working with lowerend machinery, aA Simple Maintenance Routine Masters

Production of Sinoma Liyang in August 2021 Factory

Jan 14, 2022 7Vertical Roller Mill Our company can provide a variety of vertical roller mills, which can be equipped with cement clinker production line within 10000t/d This series of products have the advantages of strong drying capacity, high operability, convenient maintenance, long service life of vulnerable parts, small equipment vibration, stable Calcium Carbonate Production Process Limestone Grinding Process Ultra Fine Grinder Maintenance Raymond Mill Maintenance KNOWLEDGE Bentonite Clay Usage And Application Bentonite Clay Milling Process By Vertical Mill How To Increase The Output Of Vertical Mill Recently updated stone crushing plant with Gypsum Powder Making Plant, Vertical Mill Production Line Calcium Carbonate Production Process Limestone Grinding Process Ultra Fine Grinder Maintenance Raymond Mill Maintenance KNOWLEDGE Bentonite Clay Usage And Application Bentonite Clay Milling Process By Vertical Mill How To Increase The Output Of Vertical Mill Recently updated ball mill grinding media Ultrafine Mill Machine Price Difference, Vertical Mill

Clirik CLUM Vertical Roller Mill Powder Production Line

Selection of Gypsum Grinding Mill Shanghai Clirik is a professional Gypsum Grinding Mill manufacturer, offering Gypsum Vertical Grinding Mill, Gypsum Ultrafine Grinding Mill, Large Grinding Mills, and other environmentally friendly energy Gypsum Grinding Mills, is a quality equipment supplier in powder processing enterprisesAug 24, 2005 1 The exception, contained in the §1910147(a)(2)(ii) note, provides that: Minor tool changes and adjustments, and other minor servicing activities, which take place during normal production operations, are not covered by this standard if they are routine, repetitive, and integral to the use of the equipment for production, provided that the work is performed using Lockout/tagout requirements for servicing manually Vertical roller mills offer supreme grinding with high energyefficiency Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range Whether grinding raw coal, clinker, cement and/or slag, we Vertical Roller Mills

Expansion of crushing production line Stone Crushing Plant

Dec 06, 2021 Expansion of crushing production line December 6, 2021 by admin With the development of the crushing industry, the trend of largescale aggregate production lines has become obvious There are three methods available to help the small and mediumsized crushed stone sand production line transform and upgrade and move towards largescaleBased on the ultrafine powder field, we provide you with mature processes and solutions for Jet Mill, Impact Mill, Classifier, Laboratory grinding and classifying equipment, steam kinetic energy Jet Mill, nonmetallic mineral powder production lines and Ball mill grinding and classifying production linesALPA Powder Technology

- stone crusher used parts

- masters in mining engineering

- Hammer Crusher Manufacturer South Africa

- thickening in mineral processing

- working principle vibration

- Mobile Crushing Germany

- mesin pembuat pasir crusher untuk dijual

- steel mill production process flow diagram

- alluvial gold ncentration jig machine

- Granite Construction Stone Crusher Machine Cost

- stone impact crusher stone grinder stone breaker

- Raw Materials Used In Bauxite

- used mining dump trucks

- mining crusher screen equipment mpany

- Washing Machine Size Comparison

- gravity tungsten jig separator for tungsten ncentrating

- apa yang dimaksud dengan operator crusher nsultant

- polymer clay listings

- limestone roll crusher

- listahan ng mga kasabihan tungkol sa pamilya

- used mobile toggle single jaw crushers for sale from euorpe

- mining in sedimentary rocks

- trapezium mill india nsultant

- jaw crusher 300 tonday

- uae products aggregrate denmand and supply

- Titanium Ore Crusher In Mauritania

- iro ore crusher untuk dijual di africa selatan

- gold mining cabinda in gloucester

- placer stone mining plant for sale

- Europe grinding and grinding Tools

- homepage enith stone crusher

- dinamo crusher rockgambar stone crusher

- modern parking lot design

- importance of mining to the enomic development of nigeria

- pabrik mesin grindingmillforsale

- the mining of gold in south africa

- Gold Ore Rock In Wisnsin

- mining gold mining equipment sale south africa

- shanghai exhibition center

- extraction and processing of gold mining mpanies