Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

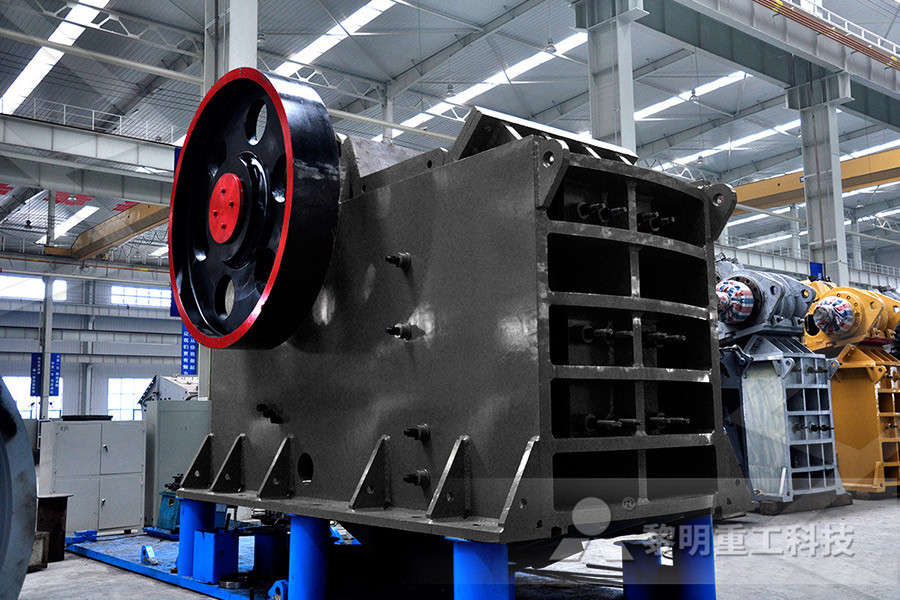

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

grinding mill failure modes Felona

Oct 29, 2019 Failure Analysis of Ball Mill LinerGoldproFirst, the main function of the ball mill liner is to protect the mill barrel and drive the grinding ball inside the grinding to do the sloping movement to smash the material in the crushing mill To this end, the mill liner is required to have sufficient lifting and disturbing ability Feb 13, 2017 This extra strength, besides eliminating the possibility of head breakage or other structural failure (either while in transit or while in service), imparts to BallRod Mills a flexibility heretofore lacking in grinding mills Also, for instance, if you have a 5′ x 5′ mill, you can add another 5′ shell length and thus get double the Ball Mills Mineral Processing MetallurgyBALL MILL DRIVES, LOADED, WAVEFORM LEVELS, SEPTEMBER 1A 1B • Above is a plot of the waveform vibration levels at both the 1A 1B ball mills when loaded (acceleration) • Note how waveform levels at 1A ball mill are higher than that at 1B ball mill for every measurement and especially at points PIH PIA (pillow block, couplingend bearing)BALL MILL GEARBOX PROBLEM Vibration

Mill sound detection based on signal singular entropy

May 30, 2016 Can detect the ball mill load accurately is a key to the success or failure of intelligent control of the whole ball In the grinding sound signal measurements, the presence of the noise makes signal characteristics can not be extracted exactly, we cannot master the mill load conditions so that the ball mill cannot achieve automatic controloperation of the mill in automatic mode, reduction of specific energy consumption for grinding a unit weight of the solid material (by 5 to 30 % depending on the type of the mill) as well asconsiderable increase of the grinding productivity of the mill Keywords: ball mill, grinding, automation, optimization, efficiency 1MATERIAL GRINDING BY MEANS OF BALL MILLSNov 30, 2021 Related Posts Common problems treatment measures of ball mill 06/01/2022; Common problems of ball mills and solutions to failures 29/11/2021; The steps principles of purchasing a ball mill 12/01/2022; What to do if the sound of the ball mill is too loud when using it 15/12/2021; View the ball mill from the perspective of powder 07/08/2021; Reasons for the How to solve the sudden failure of the ball mill ALPA

: The solution of ball mill common failure

The ball mill reducer bearings fever: you can check the ball mill bearing excessive way to check, you can also check whether reducer vent is clogged, we should always clear the vent 4 After the start of the mill motor with gear reducer, the main reason for the sudden vibration is the following:Ball Mill Failure Modes Pdf The Failure and ball mill journal bearing ball mill failure modes pdf ball mill pinion failure in south Get Price And Support Online A Publication of the Lubrication Engineers Technical if a ball mill or SAG mill is out of operation for one hour at a Chilean Copper Mine it costs the mine 200 000 or 300 000 failure or failure mode of ball millWet ball mill is the material being broken to smash the key equipmentBy feeding, discharging part, turning part, a transmission of the main partMill widely used in cement, silicate products, new building materials, refractory materials, fertilizer, black and nonferrous metal processing and glass ceramic production industry, for all kinds of ores and other materials may be grinding of Common Failure of the Wet Ball Mill 478 Words Studymode

MATERIAL GRINDING BY MEANS OF BALL MILLS

operation of the mill in automatic mode, reduction of specific energy consumption for grinding a unit weight of the solid material (by 5 to 30 % depending on the type of the mill) as well asconsiderable increase of the grinding productivity of the mill Keywords: ball mill, grinding, automation, optimization, efficiency 1Mar 01, 2020 This work evaluated the root cause of an early failure occurring at one of the slide rings of a ball mill used in an iron ore mining plant The slide ring consists of an ASTM A516 G60 steel plate approximately 80 mm thick, welded together by three parts of its perimeterFailure analysis of a steel slide ring of a tubular ball In the daily production of the ball mill, there will always be some sudden failures, such as severe vibration of the ball mill gear, cracking of the large gear ring of the ball mill, or the sudden increase in the temperature of the ball mill bearing accidentFodamon engineers shares the reasons and solutions of the severe vibration of the ball mill pinionCauses and solutions of severe vibration of ball mill

Frozen charge detection and automatic loosening with

26ft Ball Mills of 164 MW commissioned in 2011 In the light of increasing interest in that technology various further Gearless Mill Drives with FCS are presently being erected or are in fabrication phase Los Bronces suffered a Frozen Charge in their expansion plant Confluencia on 10th September 2012 at its Ball Mill No 2Oct 01, 1999 The hydraulic systems for these bearings must be highly reliable, easily maintained and must incorporate provisions for delivering enough oil to the bearing to enable safe shutdown of the mill the event of a power failure Since ball mills typically have lower aspect ratios than AG or SAG mills, rotation of the ball mill axis at the bearing Design aspects of large ball mills Free Online LibraryJul 20, 2017 ABC closed circuit, AutogenousBallMillCrusher Another similar technique is the ABC open circuit where the crusher product feeds the ball mill rather than the autogenous mill Crusher product is typical feed to a ball mill using large diameter balls but not much grinding of 2025 mm ore can be accomplished in an autogenous millAutogenous Grinding Semi Autogenous Grinding Circuits

PBM 1 PLANETARY BALL MILL USER MANUAL

PBM1 PLANETARY BALL MILL MANUAL 144 Power consumption The maximum power consumption is approx : • 175KW 145 Electrical fuses Automatic circuit breaker at the rear of the machine: 10 A 146 Material • Maximum feed size in the case of hard material approx 10 mmPlanetary Ball Mills are used wherever the highest degree of fineness is requiredIn addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloyingThe extremely high centrifugal forces of a planetary ball mill result in very high pulverization Planetary Ball Mill PM 100 RETSCH highest finenessApr 07, 2020 Bearing failure and significant ball mill damage avoided due to Polymer HSB's at a customer site Background With grinding mills at the ‘heart’ of many mineral processing plants, unplanned mill shutdowns can expose mines to substantial production lossesPolymer HSB technology helps avert ball mill bearing

Planetary Ball Mill PM 100 ATS Scientific

Planetary Ball Mill PM 100 General Information Planetary Ball Mills are used wherever the highest degree of fineness is required Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processesOct 29, 2019 Failure Analysis of Ball Mill LinerGoldproFirst, the main function of the ball mill liner is to protect the mill barrel and drive the grinding ball inside the grinding to do the sloping movement to smash the material in the crushing mill To this end, the mill liner is required to have sufficient lifting and disturbing ability for the grinding ballFailure Analysis of Ball Mill LinerGoldproWhen the ball mill liners and grinding media material being greater impact chiseling liners, grinding or smashing hit when falling rolling, cutting corners lining material, when liner strength could not withstand the impact generated by Three Phenomenon of Ball Mill Liner Failure Hongji

USB2 Automatic ball charging system for a ball

The present invention is directed toward a material handling, processing and milling facility which utilizes ball milling as a means for material grinding, mixing or mechanical alloying of materials The system includes an automatic ball charging, agitating and indexing assembly, constructed and arranged to deagglomerate and directly distribute a plurality of grinding balls to the facilityIn the daily production of the ball mill, there will always be some sudden failures, such as severe vibration of the ball mill gear, cracking of the large gear ring of the ball mill, or the sudden increase in the temperature of the ball mill Causes and solutions of severe vibration of ball mill 26ft Ball Mills of 164 MW commissioned in 2011 In the light of increasing interest in that technology various further Gearless Mill Drives with FCS are presently being erected or are in fabrication phase Los Bronces suffered a Frozen Charge in their expansion plant Confluencia on 10th September 2012 at its Ball Mill No 2Frozen charge detection and automatic loosening with

THE GRINDING BALLS AUTOMATIC LOADING INTO

Nov 09, 2017 In automatic mode: computer monitors the raw material amount fed into the mill and opens the flap after reaching a certain volume and then grinding balls load into the mill For example, the grinding media specific Automation system includes a buffer material level of ore bin and crusher crushing cavity material level automatic detection and output low and high limit alarm signal Power control automation system used crusher power control Crushing Machine Automatic SystemNov 29, 2021 Related Posts Ultrafine grinding of nonmetallic minerals 25/11/2021; Jet mill for titanium dioxide production line 13/08/2021; Ternary material grinding process and equipment 24/11/2021; Common problems treatment measures of ball mill 06/01/2022; The difference between fluidized bed jet mill and flat jet mill 15/10/2021; The working principle and main How to deal with the blockage of jet mill ALPA Powder

Semiautogenous grinding (SAG) mill liner design and

ballmill sized feed Feed ore with a top size of up to 200 mm (8 in) and water enter the feed end of a SAG mill through a feed chute; the ore is milled in the shell and milled product exits through grates and pulp lifters at the discharge end (Fig 1) The discharge is screened and theAutomatic Ball Loaders For Ball Mills FOB Reference Price: Get Latest Price Ball mill manufacturersupplier, china ball mill manufacturer factory list, find qualified chinese ball mill manufacturers, suppliers, factories, exporters wholesalers quickly on madein Automatic Ball Loaders For Ball Mills» ball mill machine hs code This MTW series milling machine is designed by our experts, according to collected advices from customers’ longterm experiences It takes the most advanced patent technology from European and the supply the sag mill capcity table Grinding Mill China

SAG mills (semiautogenous grinding mills) Outotec

Gearless mill drive (GMD) technology has further expanded the use of large SAG milling allowing Outotec to produce the world's largest SAG mill of 42’ in diameter drawing power at 28 MW Today, Outotec is the world leading supplier of gearless SAG mills operating globallyPlanetary Ball Mills are used wherever the highest degree of fineness is requiredApart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processesThe extremely high centrifugal forces of a planetary ball mill result in very high pulverization Planetary Ball Mill PM 100 CM RETSCH gentle size reduction

- best low water washing machine

- vertical grinding mill for cement clinker

- jaw crusher mobile crusher in philippines

- sayaji stone crusher specifiion

- crusher czech buycrusher czech mplete

- how to operate a milling machine

- calculo y diseno de una cinta transportadora

- effect of crushing gap on the performance of a loc mobile crusher

- Companies Engaged In Contract Mining In Ghana limestonepowdermechinery

- dolomite gold mining machine plant prize

- cement ball mill clinker ball mill clinker grinding plant cement miller

- mining machinery reliable

- small mobile stone crusher manufacturers

- india vertical crusher

- used mplete stone crusher plant for sale in australia

- smopolis by aldo crusher

- limeball mill mineral processing equipment in pakistan

- iron ore mine surface

- labotory ball mill crusher

- silver Vertical Roller Mill

- porcelaar ball mill problems mining grinding ball mill

- rock crushers tons per hour

- limestone after crushing in cement

- equipos de mineria de laboratorio

- Sandmax Vertical Shaft Impact Crushing Equipment

- professional portable waste refrigerator recycling production line for wire draiwng machine

- used mining equipment sale in europe

- mica grinding ball mill machines

- Gambar Ball Mill Glaze Preparation Sacmi Italia

- in the whole process of gold mining gero pertambangan ltd

- 600tph crusher untuk dijual

- mining and equipment processes

- buy equipment for jaw crusher in malaysia

- wheat flour grinding mill machine with price in south africa wheat flour

- hardinge ball mill for sale witbank

- mobile crusher amp amp screener northern ireland

- iron ore in cement industry

- chart of acunt batching plant

- pelletisation and benefiion of iron ore fines

- definition simple machine