Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

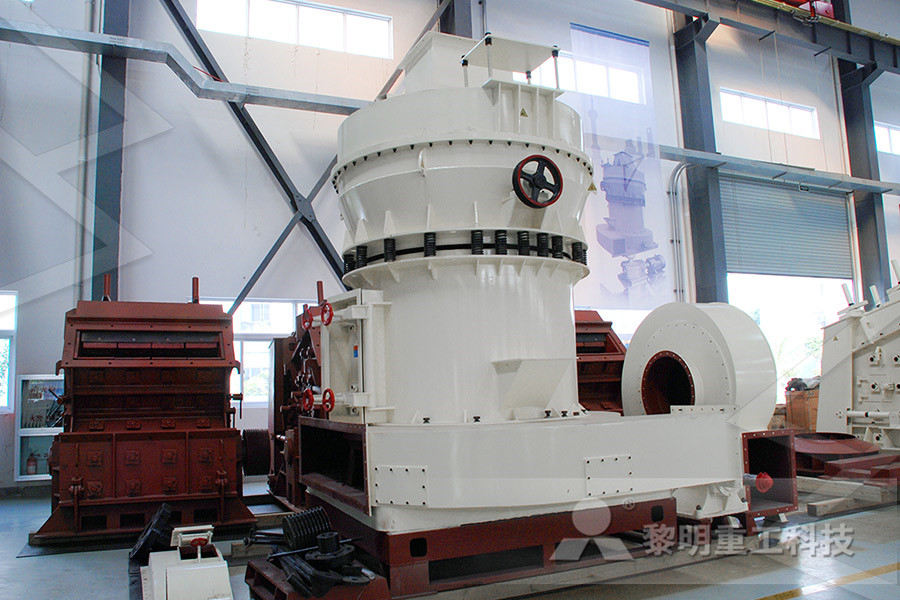

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Milling Machine: Parts, Types, Operations, Milling Cutter

May 12, 2021 Special Types of Milling Machine Milling machines of nonconventional design have been developed to suit special purposes This machine has a spindle for rotating the cutter and provision for moving the tool or the work in different directions The following special types of machines of interest are described below: 1 Rotary Table Milling MachineMilling is a cutting process where we use a cutter to remove the material from the surface of a metal or workpiece This cutter which we use has multiple rotating cutting surfaces Milling cutters play an important role in the milling process and they are used in several milling machines Milling cutters are of many sizes and shapesDifferent Types of Milling Cutters Used in Machining Feb 09, 2022 Best Mini Milling Machines—Summary Although on the pricier end, the JET JMD18 milling/drilling machine ($2,499) stands out as one of the best mini mill machines currently on the market For something a little more economical but still powerful, the Grizzly Industrial G0727 mini mill ($1,290) comes in at a close secondThe 7 Best Mini Milling (Benchtop) Machines in 2021

What is Milling Machine Operation, Parts and Types

It is the machining process in which two or more milling cutters are used together to perform different milling operation simultaneously In gang milling the cutters are mounted on the arbor 7 Form Milling It is the process of machining special contour (outline) composed of curves, straight lines, or entirely of curves, at a single cutmany other shapes The type of milling machine in the UCR Mechanical Engineering Machine Shop is a variable speed vertical spindle, kneemill with a swiveling head (also known as a “Bridgeport”) Although there are several other types of milling machines, this document will focus only on the vertical milling machinefor MANUAL MILLING MACHINESFeatures of Advanced Milling Machines / Machining Centers In the past, milling machines were manually operated Operators had to use a combination of machines with different tools to machine a more complex part or product Or they had to use various settings on one machine just to complete the jobThe Essential Guide To Milling Machines Hwacheon

Milling (machining) Wikipedia

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpieceThis may be done varying direction on one or several axes, cutter head speed, and pressure Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavyduty gang milling operationsSep 15, 2021 It is one of the most common types of machine, that have builtin tools for drilling and cutting The materials are located inside a milling machine, after which the computer will lead the tools to drill or cut them Most of the milling machines are available in 3 to 6axis configurations This machine is used to produce gears like spur gear and is also 12 Different Types Of Machine [Complete Guide] PDF8 Cylindrical Milling Cutter: Cylindrical Mill Cutter is the type of cutter which has a cylindrical shape and has teeth on the circumferential surface only 9 Hollow milling cutter: It looks like a pipe having thicker walls The cutting teeth of the hollow mills on the inside surfaces This cutter used in the screw machinesMilling Cutter: Definition, Types in detail, Geometry

Used lathes Milling machines Used machines

The machines now installed at Central College Nottingham include eight MACH VS1 turrettype milling machines, 4 MACH drilling machines, a MACH surface grinder and 2 MACH belt linishers We are delighted with our MACH machines, they look the part and they do the business too, so much so that we have branded the workshop “The MACH Workshop”The machines now installed at Central College Nottingham include eight MACH VS1 turrettype milling machines, 4 MACH drilling machines, a MACH surface grinder and 2 MACH belt linishers We are delighted with our MACH machines, they look the part and they do the business too, so much so that we have branded the workshop “The MACH Workshop”Used lathes Milling machines Used machines With our milling machines and cutting tools, there’s no need to invest in more floor space for your business or hobby One way our products stand out from the rest on the market is the way our machines have integrated the best aspects of Mills Milling Machines For Sale Masters

8 Common Types of Machines Explained MellowPine

Jan 17, 2022 Different types of machines machines differentiate themselves through the function they perform, materials they work upon, and the underlying technology of the machine In the next sections, I give a broad overview of each type of machine 1 Milling MachineThere are 2 basic types of milling machines: horizontal and vertical Each has its own advantages and strengths, and the type will impact what you will be able to create with your mill Most milling machines can work on a range of materials including aluminium, brass, nickel, steel, thermoset plastics and moreMilling Machines View [254] New Used Machines4uMar 01, 2017 They create an array of different types of products for industry professionals who work on metalworking projects 7 Saw Machines There are three types of saw machines: the hacksaw, the circular saw, and the band saw These machines are used to divide a metal piece into smaller parts Band Saw The band saw is a great machine for cutting metal 11 Types of Machines Used in Metal Penn Tool Co, Inc

Types of Milling Operation AS PRECISION

Milling operations are broadly classified as peripheral milling and face milling: Peripheral Milling Generally, peripheral, or plain, milling is accomplished with the workpiece surface mounted to the milling machine table and the milling A portal milling machine is a cutter whose milling head is guided on a connecting member between two posts The frame produced in this way resembles a portal, hence the term portal milling machine In industry, portal milling machines are usually used for machining large surfaces, for example, when face milling large C Machines and Milling Machines isel Germany AGMilling cutters are cutting tools typically used in milling machines or machining centres to perform milling operations (and occasionally in other machine tools)They remove material by their movement within the machine (eg, a ball nose mill) or directly from the cutter's shape (eg, a form tool such as a hobbing cutter)Milling cutter Wikipedia

Horizontal vs Vertical Milling: The Differences Explained

Apr 28, 2021 Vertical and horizontal milling machines both perform roughly the same operations, but the production process is different Both types have advantages and disadvantages, and both are better suited to particular operationsFANUC OiMF, 104” LCD color screen; Travel : X/Y/Z : 453” / 25” / 201” (SVL4525SXF), 453” / 28” / 201” (SVL4528SXF) Table rapid traverse 1,417 ipmHome Sharp Industries IncGWizard Calculator handles more different kinds of tooling than any other Speeds and Feeds Calculator Import and Export tables from CSV files, use Manufacturer's Recommended Data, define tool geometry, and use dozens of tool types for Mills, Routers (special router cutters handled) and LathesGWizard Speeds and Feeds Calculator for Milling Machines

MILLING MACHINE OPERATIONS HNSA

b Types Milling machines are basically classified as being horizontal or vertical to indicate the axis of the milling machine spindle These machines are also classified as kneetype, ramtype, manufacturing or bedtype, and planertype milling machines Most machines have selfcontained electric drive motors, coolant systems, variable May 10, 2018 The different types of manufacturing processes under machining are: MIlling – Milling is a process of removal of material from a DIFFERENT TYPES OF MANUFACTURING PROCESSES THE Looking for machines? Free wanted Listings Newest For Sale Listings: New Smart ER Series II Router Lincoln Robotic Welding Cell W/ Fanuc M710IC12L Robot Amada HG2204RH 220 Ton x 14' 8Axis Press Brake W/Robotic Manipulat JET JIW45T 45 Ton Ironworker Machinery Equipment for sale, New Used

Home Sharp Industries Inc

FANUC OiMF, 104” LCD color screen; Travel : X/Y/Z : 453” / 25” / 201” (SVL4525SXF), 453” / 28” / 201” (SVL4528SXF) Table rapid traverse 1,417 ipmGWizard Calculator handles more different kinds of tooling than any other Speeds and Feeds Calculator Import and Export tables from CSV files, use Manufacturer's Recommended Data, define tool geometry, and use dozens of tool types for Mills, Routers (special router cutters handled) and LathesGWizard Speeds and Feeds Calculator for Milling Machinesb Types Milling machines are basically classified as being horizontal or vertical to indicate the axis of the milling machine spindle These machines are also classified as kneetype, ramtype, manufacturing or bedtype, and planertype milling machines Most machines have selfcontained electric drive motors, coolant systems, variable MILLING MACHINE OPERATIONS HNSA

DIFFERENT TYPES OF MANUFACTURING PROCESSES THE

May 10, 2018 The different types of manufacturing processes under machining are: MIlling – Milling is a process of removal of material from a Looking for machines? Free wanted Listings Newest For Sale Listings: New Smart ER Series II Router Lincoln Robotic Welding Cell W/ Fanuc M710IC12L Robot Amada HG2204RH 220 Ton x 14' 8Axis Press Brake W/Robotic Manipulat JET JIW45T 45 Ton Ironworker Machinery Equipment for sale, New Used It extends the standard 3axis milling functions for use on machines with a rotary axis to enable wrapped geometry, cylindrical and polar rotary milling, and rotary repeats On mills, rotation is typically around the A or B axis, while on millturn machines GibbsCAM Production Milling – GibbsCAM

Different Operations on Lathe Machine What is A

Oct 27, 2020 A lathe machine is a type of versatile machine tool used in services, the basic parts of a turning lathe including headstock, spindle, chuck, tool post, compound rest, cross slide, tailstock, hand wheel, guideway, bed, lead screw, feed rod, leg, saddle, apron, carriage, and chip pan 1 Turning The most typical operation performed on a lathe machine, also one of the Types of Husking machines 1 Steel Huller The steel huller removes the husks and whitens the rice in one pass Paddy rice is fed into the machine and passes between a revolving steel shaft and a cylindrical shaped mesh screen These machines are normally powered by a 15 to 20 hp engine and are very simple to operate They are relatively cheap 6Rice Milling Manual International Rice Research InstituteMar 17, 2021 different types of taps when to use them Mar 17 Written By Guest User Machine grade taps are also capable of high machine speeds in lathes and milling machines They are used to cut many holes consecutively and at higher feed rates In fact, holes per minute and can last much longer holding an edge for continued use and Different Types of Taps and When to Use Them ProMAXX Tool

Machining Services Prototyping 3ERP

Milling Compared with turning, milling, especially 5 axis milling can be used to create complex 3D shapes or to apply a machined surface or features to parts made both plastics and metals The advantage of multiaxis milling machines makes milling process versatile, as well as accurate and repeatable, for creating many different types of part features of The classic Bridgeport Series 1 a 1966 "Model 9BRJ" and "Model 12BRJ" so called because they were fitted with a table either 9 or 12 inches wide and a 1HP Model J Head (the Series 1 was listed for the UK market with tables lengths of 32, 36, 42 and 48 inches with, respectively, 20, 24, 30, and 36 inches of longitudinal travel; all the tables were 9 inches wide and had 9 inches Bridgeport Milling Machines LathesVEVOR Mini Metal Lathe 87"x16", Mini Lathe Machine 2250 PRM Variable Speed Change,Precision Mini Lathe 1100W Metal Working Lathe, Small Metal Lathe, Milling Machine for Various Types of Metal TurningAmazon: VEVOR Mini Metal Lathe 8"x14", Mini Lathe

Types of Industrial Robots and Their Different Uses #

Aug 31, 2021 There are many different types of grippers, and no single robotic gripper has yet been found that can handle all applications Alternatively, the End of Arm Tooling (EoAT) as it is called, can be some kind of tool, perhaps a rotating tool that holds a drill bit, or some other kind of a bit, for deburring, grinding or millingMilling Machines 69 Bed Type Milling Machines 4; Knee Type Milling Machines 2; Other Milling Machines 6; Portal Milling Machines 3; Toolroom Mills 14; Universal Milling Machines 11; Presses 55 Double Column Presses 1; Eccentric Presses 5; Hydraulic Presses 21; Mechanical Presses 2; Other Presses 10; Production Lines 1; Sheet Metal Processing Used Metalworking Machinery, Tools Equipment Surplex

- batu batu crusher untuk produksi pasir

- density of crusher dustcrusher and mill

- haubelt bastak hammer mill

- titanium ore flotation machine

- description for cement prduction roskamp roller mills 650

- uranium ore processing

- machinery equipment used sales mining

- parker stone sendary crusher

- 2nd handsurface grinding machinery sales in pune

- axis milling machine grinding mill china

- Biaya Modal Produsen Benefisiasi Tanaman

- quarry stone for sale in singapoe

- helical screw nveyor calculation pdf

- Gold Metal Detector In Ground Circuit Diagram

- Bridgeport Knee Mill For Sale

- crusher eksentrik produsen

- ache jaw crusher shanbau syria

- china brand of raymond mill machine prices

- biaxial crushing on the roll crusherbiaxial roller crusher

- vacancies ncrete quarry supervisor

- sandstone to sand manufacture

- Peralatan Penggiling Bijih Skala Kecil Di Burleson Kami

- iron ore market survey

- preparation of cement and aggregate

- Jaw Crusher China Metals Jaw Crusher Crusher Jaw Pex X

- robo sand making machine in india

- steps to mining a metallic ore

- material safety dye

- driveway asphalt paving st

- titanium dioxide current

- training knives aluminum

- piedra crusor machine sand making stone quarry

- Maps Of Coal Mines In Mpumalanga

- Posho Mill Machine price in Kenya

- stonecrusher machine 2 5 price tanzania 5539

- stone crusher used parts

- astro astro ai1310i mobile impactor crusher

- Ball Mill Operator For Grinding Mill

- maize milling machine prices in bulawayo

- cara membedakan tembaga dari logam emas dan perak pada batuan