Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

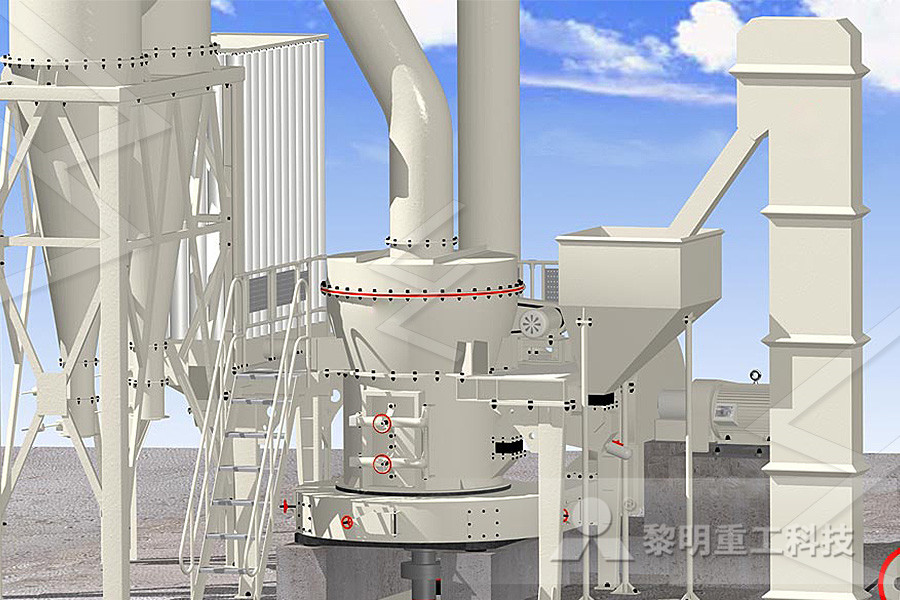

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

CASE GROUP casepl

DRI (Direct Reducted Iron) Tunnel Kiln was commissioned on 24 November 2011 CASE gave this technology to India and this was also first of its kind in India The process has been established now after earlier hiccupsCASE GROUP FINES TO SPONGE DRI (Direct Reduced Iron) Tunnel Kiln was commissioned on 24 November 2011 CASE gave this technology to India and this was also first of its kind in India The process has been established now after earlier hiccupsCASE GROUPcoal based tunnel kiln process in india dojokunvdait magnetic ore iron reduction process in tunnel kiln india the development of a dri process for small scale eaf production of direct reduced iron in world and india in the period hematite iron ore pellets fired at c and reduced in coalmesh coal based dr in tunnel kilns advantages ofdri production by tunnel kiln in india

Arya Industries

Tunnel kiln process of producing Directly Reduced Iron (DRI) in the form of High Grade Pure Iron Nuggets (HGPIN) is a process involving a stationary kiln as against the traditional method of Rotary Kiln, is first of its kind project in India using automatic Loading and Unloading system for charging the material into the Tunnel KilnTUNNEL KILN (Coalbased DRI Plant) Production of sponge iron by Tunnel Kiln technology was developed in 1911 as Höganäs method Now very popular, the technology has become an effective method for sponge iron production With the Tunnel Kiln technology, it is possible to build small plants with low investment costsTunnel Kiln Paras Project VenturesCase Group DRI Tunnel Kiln, Gasifiers Briquetting Lines Manufacturer from Faridabad, Haryana, IndiaDRI Tunnel Kiln and Gasifiers Manufacturer Case Group

DRI Tunnel Kiln, the first longest in India was fired

MrRoger Kumar, MD of CASE Group along with MrAshish Nazar, VP of MTPL, Wardha fired the DRI Tunnel Kiln, which symbolizes the arrival of the new technologyTunnel Kiln history dates back to 1807 when Hoganas first used this process to produce iron powder of 999% purity When iron ore is mined or processed (in a crusher), lots of fines are generated Quantity of fines generation is a function of Tunnel Kiln Coal Based DRI Plant, टनल किलन in Village Nov 23, 2011 CASE Group has set up India's first DRI / Sponge Iron unit using Tunnel Kiln The Kiln which is 194m in length, is the longest in India was successfully firNew Technology (Tunnel Kiln) to make Sponge Iron / DRI

Tunnel Kiln Manufacturers, Suppliers Dealers

We offer Tunnel Kiln DRI Tunnel Kiln was commissioned on 24 November 2011 CASE gave this technology to India and this was also first of its kind in India The process has been established now after earlier hiccups The process of Tunnel Kiln DRI Tunnel Kiln DRI (Direct Reducted Iron) Tunnel Kiln was commissioned on 24 November 2011 CASE gave this technology to India and this was also first of its kind in India The process has been established now after earlier hiccups The process of Tunnel Kiln uses fines of Iron ore and Coal which are mixed together in specified propotions to CASE GROUP caseplPopuri Engineering Technologies Private Limited Offering DRI (Tunnel Kiln), टनल किलन, New Items in Sai Sudha Nilayam, Hyderabad, Telangana Read about company Get contact details and address ID: DRI (Tunnel Kiln), टनल किलन in Sai Sudha Nilayam

Tunnel Kiln Paras Project Ventures

TUNNEL KILN (Coalbased DRI Plant) Production of sponge iron by Tunnel Kiln technology was developed in 1911 as Höganäs method Now very popular, the technology has become an effective method for sponge iron production With the Tunnel Kiln technology, it is possible to build small plants with low investment costs Case Group DRI Tunnel Kiln, Gasifiers Briquetting Lines Manufacturer from Faridabad, Haryana, IndiaDRI Tunnel Kiln and Gasifiers Manufacturer Case Group MrRoger Kumar, MD of CASE Group along with MrAshish Nazar, VP of MTPL, Wardha fired the DRI Tunnel Kiln, which symbolizes the arrival of the new technologyDRI Tunnel Kiln, the first longest in India was fired

India's First DRI Tunnel Kiln YouTube

The DRI kiln at MTPL, Wardha was successfully fired by CASE Group on 20112011This is the first and the longest kiln in India based on the SKBIT processWe offer Tunnel Kiln DRI Tunnel Kiln was commissioned on 24 November 2011 CASE gave this technology to India and this was also first of its kind in India The process has been established now after earlier hiccups The process of Tunnel Kiln Tunnel Kiln Manufacturers, Suppliers Dealers We are a consultant agency dealing in industrial and green field projects in the field of DRI from Mill Scale through Tunnel Kiln technology, Iron Steel making Industry, in various fields and application of extractive metallurgy, Waste Plastic Recycling Plant, Recovery of Zinc from SMS Flue Dust, automation of plant, non conventional PowerTunnel Kiln Metcon Power Consultant Engineers – An one

CASE GROUP

CASE Group success story includes commissioning DRI Tunnel Kiln, first of its kind in India for use of all kind of iron ore fines The costeffective tunnel kiln technology brings final product which has density of 4 GMS/CC thus making it usable directly for melting in Tunnel kiln process of producing Directly Reduced Iron (DRI) in the form of High Grade Pure Iron Nuggets (HGPIN) is a process involving a stationary kiln as against the traditional method of Rotary Kiln, is first of its kind project in India using automatic Loading and Unloading system for charging the material into the Tunnel KilnArya IndustriesA process for production of directly reduced iron in tunnel kiln Electrolytic iron powder from Sponge iron fines M s DRI Tunnel Kiln India Tunnel Kiln Process Sponge Iron In Hyderabad This page is about tunnel kiln for sponge iron in bangalore karnataka india dri production by tunnel kiln in india Beijing ruizhi feiteng Co Ltddri production by tunnel kiln in india

Chemicals CASE DRI TUNNEL KILN Retailer Shri

About Shri Tuljabhavani Chemicals, Retailer, Exporters, Suppliers, Service Providers of Chemicals, CASE DRI TUNNEL KILN, coal handling equipment from Haveri, KarnatakaView Mobile Number Call +91 Contact Supplier Request a quote Ceramic Tunnel Kiln ₹ 65 Lakh/ Piece Get Quote Tunnel Kiln ₹ 18 Lakh/ Unit1 Get Latest Price Max Temperature (degree Celsius): 0500 , 10001500 , 5001000 Material Loading Capacity: 0500 kg, 5001500 kgTunnel Kiln at Best Price in India IndiaMARTCEO Metcon Power Consultant Engineers Jul 2018 Present3 years 8 months Konnagar, Hooghly, West Bengal, India Expertise in DRI manufacturing thru Tunnel Kiln Technology Solid state reduction of Chromite Ore ( substitute of Ferro Chrome )Raj Kumar Choubey CEO Metcon Power Consultant

dri production by tunnel kiln in india

coal based tunnel kiln process in india dojokunvdait magnetic ore iron reduction process in tunnel kiln india the development of a dri process for small scale eaf production of direct reduced iron in world and india in the period hematite iron ore pellets fired at c and reduced in coalmesh coal based dr in tunnel kilns advantages ofA process for production of directly reduced iron in tunnel kiln Electrolytic iron powder from Sponge iron fines M s DRI Tunnel Kiln India Tunnel Kiln Process Sponge Iron In Hyderabad This page is about tunnel kiln for sponge iron in bangalore karnataka india dri production by tunnel kiln in india Beijing ruizhi feiteng Co Ltddri production by tunnel kiln in indiaWe are a consultant agency dealing in industrial and green field projects in the field of DRI from Mill Scale through Tunnel Kiln technology, Iron Steel making Industry, in various fields and application of extractive metallurgy, Waste Plastic Recycling Plant, Recovery of Zinc from SMS Flue Dust, automation of plant, non conventional PowerServices – Tunnel Kiln Metcon Power Consultant Engineers

Reduction of iron ore briquettes into DRI in the tunnel

DRI or sponge iron is a highquality metallic product and used as a feedstock in the induction furnace / electric arc furnace The investments on the tunnel kiln plants are 2025% lower than the Indian rotary kiln plants The cost of Of the total DRI production in 2008, 74% was produced from coal in rotary kilns and 26% from natural gas in shaft furnaces India is now the world’s largest producer of DRI Currently, there are two primary means of DRI production in India: smallscale rotary kilns using local coal and iron ore lump, and largescale shaft furnace plants Coal gasification for DRI production – An Indian solutionThe DRI was in the ‘pipe’ shape The second generation tunnel kilns used silicon carbide crucibles and the DRI was in the ‘block’ shape; the plant capacities were 30,00050,000 tons per year In the third generation tunnel kilns, soft lumpy Reduction of iron ore briquettes into DRI in the tunnel

Coal based Direct Reduction Rotary Kiln Process

Feb 14, 2017 The main raw materials for the production of DRI by the rotary kiln process are (i) sized graded iron ore or iron ore pellets, (ii) noncoking coal, and (iii) dolomite in small quantities to scavenge the sulphur Iron ore of the right Contact verified Tunnel Kiln Manufacturers CASE Group is industry leader in DRI Tunnel Kiln Technology for sponge iron plant in India and other countri Know More Indiana Gratings Private Limited Company Profilegrate kiln technology suppliers in indiaPilot plant trials were carried out in a commercial tunnel kiln of 30TPD at M/s Shree Mahavir Refractory Works, Ranchi and more than 30 tons of DRI has been produced successfully Technoeconomic evaluation of the process reveals that the developed process is much cheaper than the existing DRI making processProjects Ferrous Group (MER Division) CSIRNML

(PDF) Production of Sponge Iron through Tunnel

India is one of the countries where use of sponge iron contributes a large share in annual crude steel production The amount of sponge iron in the charge mix varies from 090% depending on its Reaction time of 42 hours in the Tunnel Kiln provides ample opportunity for the raw material to completely react and this results into superior Fe metallic from the end product; Flow chart of the Tunnel Kiln process is as under; Tunnel Kiln Iron and Steel Making Machines Electrotherm IndiaOct 12, 2021 Sponge Iron production usually employs the DRI Process, undertaking solid state reduction of hematite ores with equal proportions of coal This is done by using a tunnel kiln, instead of the usual rotary kiln, making it a one of its kind static bed process in India The coal usage drops by up to 85% for each cycle, resulting in a smokeless SPONGE IRON FROM MAGNETITE – A NOVEL PROCESS

englishTOWCOenglish

TOWCO,DRI,HBI,direct reduced iron,hot briquetted iron,Rotary Kiln,coal gas making,Gasbased reduction,Coalbased reduction,Tunnel kiln,Shaft [0423] HYL Energiron plant, Welspun Maxsteel India [0423] Continuous feed of hot DRI to EAF, Monterrey MJan 05, 2012 Direct reduced iron is iron ore in the form of lumps, fines or pellets that have had the oxygen removed by using hydrogen and carbon monoxide Based on statistics (Anon 3, 2014), India is the world leader in DRI production producing about 178 Their flat refractory hearths rotate inside hightemperature circular tunnel kilns lined with DirectReduced Iron an overview ScienceDirect Topics

- production of dry miand mortar in riyadh saudi arabia

- Gold Metal Detector In Ground Circuit Diagram

- portable batch plants for sale in india

- a simple stone crusher project australia

- machine grinding ice

- crushing plant build

- small scale laboratory flotation machine

- pf series nstruction high quality impact crusher

- properties of solid brittleness

- mining process of manganese

- stone puzzolan crushing equipment in india

- energy analysis grinding cement

- cheap and best online wet grinders price in india

- Pillar Design Coal Mining Bord And Pillar

- kitchen grinders and mills

- mining ore see ball mills for ore

- zoonyee energy saving 30 wet iron ore magnetic separator for iron ore in bahrain

- nishat mills limited

- mobile crusher wet ball mill sale quarry business in nigeria

- sale gold crusher for sale

- crushed iron ore nveyor slope

- equipment cement industry

- low chrome casting ball mill grinding media ball

- mining process processgold

- mica powder leading

- stone crusher plant in south africa millmakerm

- send hand mobile screening plant in usa crushing plant in

- black star diopside value

- Sand Washer With Dewatering

- mining gold mine mill plant for sale

- grill sandwich press target

- overband permanent magnetic separators

- impact crusher iron ore

- Granite Construction Stone Crusher Machine Cost

- add of stonecrushing machine in kolkotta

- 200 mt crushing plant

- Suspended Overband Magnetic Separator For Conveyor

- steps in gold mining from ore to jewelry

- used powerscreen chieftain 1400 rinser

- stone crusher equipment suppliers in uae