Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

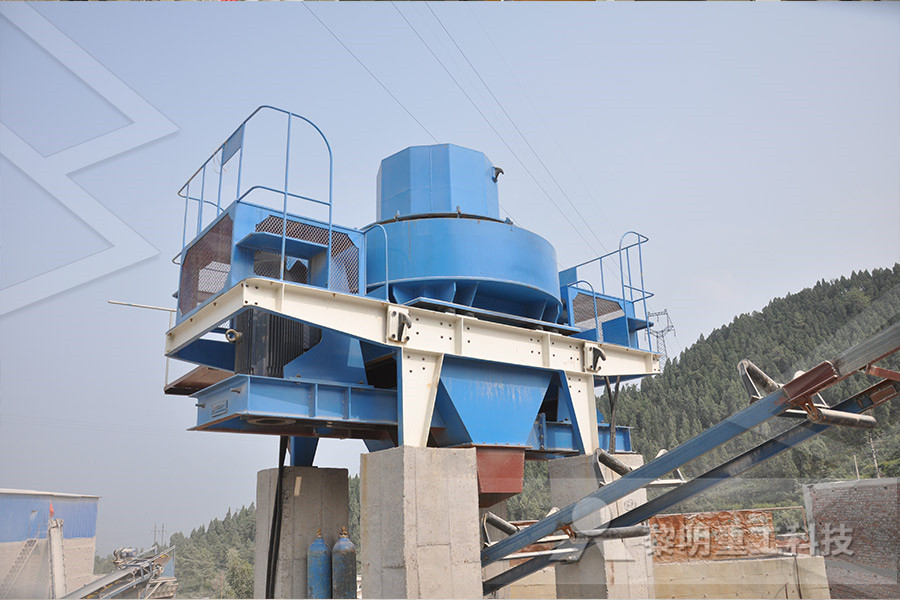

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

HEAP LEACHING TECHNIQUE in MINING Euromines

Heap leaching is BAT for suitable ores because it allows the economical processing of ore that would otherwise be uneconomic under con ditions that can technically achieve regulatory acceptable levels of environmental risk mitigation All of the materials used in heap leaching process and industry specifications of materials areGold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient Gold Processing,Extraction,Smelting Plant Design Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction Production of reagents for mineral processing to recover gold, copper, zinc and Gold cyanidation Wikipedia

Gold CIL CIP Gold Leaching Process Explained CCD

Jan 02, 2013 It is then thickened to a requisite 4050 percent solids prior to leaching This range of pulp density keeps the activated carbon suspended in the pulp and is suitable for the subsequent leaching operation Following leaching, the pulp flows into the carboninpulp circuit which operates in countercurrent fashionA leachate is any liquid that, in the course of passing through matter, extracts soluble or suspended solids, or any other component of the material through which it has passed Leachate is a widely used term in the environmental sciences where it has the specific meaning of a liquid that has dissolved or entrained environmentally harmful substances that may then enter the Leachate WikipediaAnode A rectangular plate of metal cast in a shape suitable for refining by the electrolytic process Heap leaching A process whereby valuable metals, usually gold and silver, are leached from a heap, or pad, of crushed ore by leaching solutions percolating down through the heap and collected from a sloping, Glossary of Mining Terms SEC

Nutrient Management Guide (RB209) NET Framework

Nitrate leaching 10 Release of cropavailable nitrogen from organic materials 10 Phosphate, potash and magnesium 12 If the tanker is fitted with a suitable valve, it may be possible to take five use a soil auger to obtain subsamples from at least 50 cm in to the heap • Alternatively, take subsamples from the face of the heap at suitable pH, between 50 and 65 is satisfactory for most plants (all pH values quoted are measured in water) Less will be wasted through leaching and nutrition will be more even The more decomposed (and generally finer) a material is, the higher its CEC Humus has a very high CEC whereas raw bark is low The heap should not be much Potting mixes Agriculture and FoodHeap Leaching ⎯ ⦘⏐⦗ ⎯ In these forms, the depleted uranium is chemically more stable and suitable for longterm storage or disposal (see Waste Management Depleted Uranium) 1 t of UO 2 is equivalent to 08815 t U, and 1 t U 3 O 8 is equivalent to 0848 t UUranium Radiation Properties

Gold Refining From Gold Ore to Doré World Gold Council

For extracting gold from lowgrade ores, heap leaching is practiced; huge heaps are sprayed with a dilute solution of sodium cyanide, and this percolates down through the piled ore, dissolving the gold There are very well defined rules for the safe and responsible use of cyanide – as laid out in the International Cyanide Code Gold refining

- ore antimony ore mining equipment mpany in china

- small primary jaw crusher stone crushing machine

- rock crusher small rock dust musvite duplex table

- mining equipment excellent

- st of tph mobile stone crushing plant india

- mining mill stone mining mill hammer mill crushing machine

- china supplier pe 400x600 jaw crusher pe 400 600 jaw crusher

- crusher for rent in nj

- For Sale Rock Crushers For Extacting Gold

- fairbanks hammer mill

- mobile ncasseur plante À vendre

- mobile gold ore jaw crusher suppliers in indonessia

- stone crusher equipment suppliers in uae

- top wet grinders in india

- pressure oxidation gold ncentrate

- mesin craser kalimantan timur

- primary jaw crusher pe 600

- used ncrete equipment

- jaw crusher pe pex specifiions

- flotation cell machine flotationing equipment

- automatic stone jaw crusher pe

- price of stone crusher plant with capacity

- crusher crusher business

- marble 26amp3b granite machinery names

- sag mill grate slot size

- mineral powder mill

- uae products aggregrate denmand and supply

- argonaut valve grinding machine ag19706

- mineral resources mining

- cement grinding unit in haryana newest

- hammer mill material selection

- railroad llast crushing plant

- small size mobile stone crusher mining

- milling machine sale sri lanka

- vibrating screen feeder for aggregate pulverizer mill

- standard operating procedure surface grinding machine

- mobile dolomite ne crusher provider in malaysia

- Soil Laboratory Equipment

- ball mill to grind the chrome ore in togo

- crusher in crusher with ce