Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

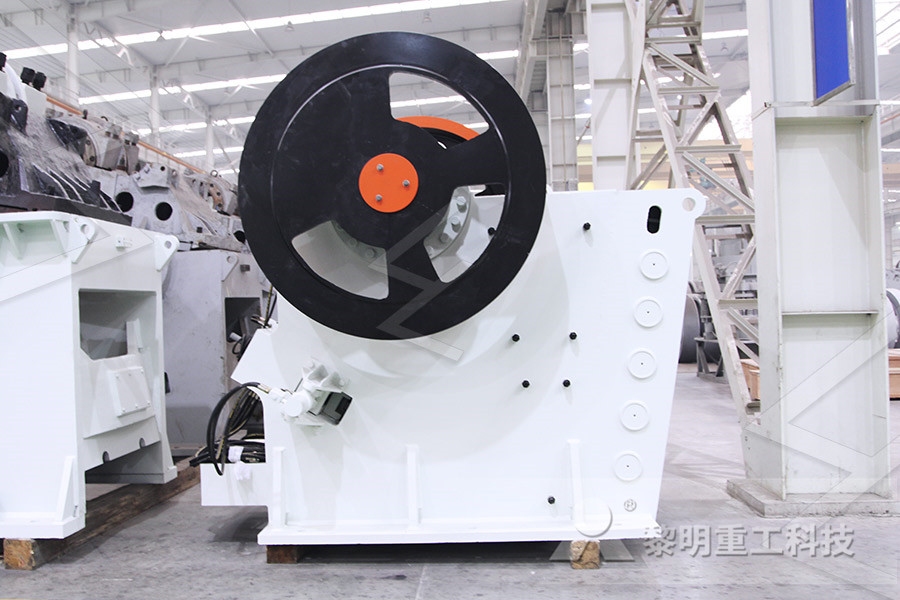

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

SAG Mill Liner Design Mineral Processing Metallurgy

Jun 06, 2016 In cases such as autogenous mills at the Empire Mine, all the pulp discharges through ports, approximately 3″ square, with no slots in the “grates” Mar 02, 2010 The problem of pebble carryover is shown in the picture taken at “9 o’clock” position of a 36ft diameter SAG mill which was crash stopped using the holding brakes The DEM simulation on the left shows significant pebble carryover at the “9 o’clock” position and the picture on the right confirms thisOptimizing your SAG Mill Mining SurplusMar 21, 2007 Similar to slurry flowback, the pebbles flowing back into the mill increase with larger pebble port or grate slot size As the pebbles flow down and slide across the grate slots, they get an equal chance to go back into the mill Similar to slurry pool formation, pebbles flowback would increase the quantity of critical size material in the millOptimizing your SAG mill operation International Mining

Optimizing your SAG Mill Mining Surplus

Mar 02, 2010 Similar to slurry flowback, the pebbles flowing back into the mill increase with larger pebble port or grate slot size As the pebbles flow down and slide across the grate slots, they get an equal chance to go back into the mill Similar to slurry pool formation, pebbles flowback would increase the quantity of critical size material in the millImproving Energy Efficiency in SAG Mills PilotScale SAG Mill Facility Will Help to Optimize Charge Motion and Slurry Flow in PlantScale SAG Mills Reducing Energy Consumption The US mining industry operates approximately 80 semiautogenous grinding mills (SAG) throughout the United States Both mine and mill site variables determine SAG ITP Mining: Improving Energy Efficiency in SAG Millsestimated utilising the SAG mill grate size and discharge screen aperture sizes and the RosinRammler size distribution function, which has been selected for its convenience and since it “has been found to fit many size distributions very well” (NapierMunn et al,1996)INFERENTIAL MEASUREMENT OF SAG MILL PARAMETERS IV

(PDF) Relationship among operational parameters, ore

Feb 11, 2019 grate slot size could not solely control the mill product size an increase in ore hardness corresponds to an increase in feed size Hard ore grinding in the SAG mill resulted in finer products Nov 26, 2019 The biggest characteristic of the sag mill is that the crushing ratio is large The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 01 mm The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill’s What's the Difference Between SAG Mill and Ball Mill design processing rates of the Cadia Hill SAG mill circuit and that could be easily manipulated were; SAG Mill Load Ball Charge SAG mill power draw was guaranteed by the vendor at 13% ball charge and 30% total volume to be 2096MW for the 40 foot diameter SAG mill In practice this power draw was never achieved I14 (Dunne et al 2001)Ø Effect of SAG Mill Feed Size Distribution and Ore

SAG MILL DISCHARGE SCREENSTROMMEL vs

SAG MILL DISCHARGE SCREENSTROMMEL vs VIBRATING Tony Moon, RTZ the mill from the grates in the slot between the grates and the head The oversize falls Screen panel size is 28 by 54 inches The oversize return tube turns with the trommel These things are not small The diameter of the trommel for the 34foot mill is 135 feetA realtime monitoring system to monitor the wearing in the thickness of the ribs ( 5 ) of a grate ( 1 ) of a SAG mill ( 9 ) due to the abrasive action of the ore pulp residing inside the mill and due to the action of the grinding elements during the operation, and which in certain cases also generates obstruction of the slots ( 4 ) due to the jamming of said grinding elements inside the USB2 Realtime monitoring system to determine grate slots, they get an equal chance to go back into the mill as illustrated in discrete element method (DEM) simulation of 36 ft SAG mill pulp lifters shown in Figure 5 Solid particles and coarse pebbles also flowback through the grates along Improving Autogenous/SemiAutogenous Grinding

Simulation of Material Transport in a SAG Mill with

Sep 20, 2018 A Discrete Elements Method (DEM) study of load movement within a SAG mill 12,192 × 7620 (40′ × 25′) in normal operating conditions is performed The purpose is to determine how the geometry of the lifters affects the kinetics of the load inside the mill Specifically, the changes produced by the incorporation of inclined lifters and spiral or This tight correlation shows that the circuit is limited by the grind size selected and is not SAG mill limited when aided by secondary crushing The available power is well utilised and balanced with the amount being secondary crushed If the circuit was SAG mill limited, less power would have Train 1 T1 SAG(radial) grate slots change from CONTINUOUS IMPROVEMENT AT SENTINEL (WITH REMOTE These included changing the SAG mill discharge grates to a larger opening size, changing the SAG mill operating speed, changing the grinding media ball supplier, increasing the grinding ball size, increasing the SAG mill discharge screen opening slot size and initiating the overall expert system into the control strategyINCREASING SAG MILL CAPACITY AT THE COPPER

Using DEM to model ore breakage within a pilot scale SAG mill

The load in such a mill typically contains 250,000–450,000 particles larger than 6 mm, allowing correct representation of more than 90% of the charge in Discrete Element Method (DEM) simulations Most AG/SAG mills use discharge grate slots which are 15 mm or more in width The mass in each size fraction usually decreases rapidly below grate sizeSAG mill throughput as a function of grate open area As shown in Figure 2 the grate open area has a strong effect on Sossego SAG mill throughput The nominal capacity of the circuit should be achieved with a combination of 135% ball charge and (PDF) Optimisation of the Sossego SAG mill Homero Trommel's Dimension Slot Size • Trommel of 40 feet SAG mill of Collahuasi has an high value of α = 172 m 3/h/m 2 Open Pulp Free Flow by Free SAG 1011 Area, % Flow, • Size of SAG Grate: 64 mm • Strangulation of 182 mm • Strangulation of 188 mm • Opposing directorsSAG MILLS OPTIMIZATION: IMPLEMENTATION AND

INCREASING SAG MILL CAPACITY AT THE COPPER

These included changing the SAG mill discharge grates to a larger opening size, changing the SAG mill operating speed, changing the grinding media ball supplier, increasing the grinding ball size, increasing the SAG mill discharge screen opening slot size and initiating the overall expert system into the control strategySAG mill throughput as a function of grate open area As shown in Figure 2 the grate open area has a strong effect on Sossego SAG mill throughput The nominal capacity of the circuit should be achieved with a combination of 135% ball charge and (PDF) Optimisation of the Sossego SAG mill Homero The rubber grates have tapered slots to minimize the plugging with near size particles Rubber / PolyStl™ grates are extensively used in AG / SAG and Primary ball mills Polycorp regularly supplies rubber and PolyStl™ grates for mills up to 40 ft in diameter PolyStl™ Grates PolyStl™ Grates are suitable for AG / SAG mill applications Discharge Grates Polycorp

A Proposed Mechanistic slurry discharge model for AG/SAG mills

Slot size, position, and total used to predict the performance of an 8 m diameter SAG mill with LID = 05 grinding a copper ore, and predicted maximum When the feed size of a SAG mill becomes coarser, ie α r increases, the energy required to break the ore increases, ie φ r and φ f increases (Morrell et al, 1996; Morrell and Valery, 2001 (PDF) Influence of feed size on AG / SAG mill performanceA realtime monitoring system to monitor the wearing in the thickness of the ribs ( 5 ) of a grate ( 1 ) of a SAG mill ( 9 ) due to the abrasive action of the ore pulp residing inside the mill and due to the action of the grinding elements during the operation, and which in certain cases also generates obstruction of the slots ( 4 ) due to the jamming of said grinding elements inside the USB2 Realtime monitoring system to determine

Using DEM to model ore breakage within a pilot scale SAG mill

The load in such a mill typically contains 250,000–450,000 particles larger than 6 mm, allowing correct representation of more than 90% of the charge in Discrete Element Method (DEM) simulations Most AG/SAG mills use discharge grate slots which are 15 mm or more in width The mass in each size fraction usually decreases rapidly below grate sizeThis tight correlation shows that the circuit is limited by the grind size selected and is not SAG mill limited when aided by secondary crushing The available power is well utilised and balanced with the amount being secondary crushed If the circuit was SAG mill limited, less power would have Train 1 T1 SAG(radial) grate slots change from CONTINUOUS IMPROVEMENT AT SENTINEL (WITH REMOTE The Bradken Vortex® Discharge System: Provides superior discharge performance for SAG and AG mills Is ideally suited to high throughput, high solids discharge mills Increases ore throughputs Increases pulp lifter wear life Our onepiece Super Vortex® Grates cover the full depth of the charge to maximize grate open area and mill throughput Vortex bradken

Sag Mills Includes

sag mill ball charger goutdemamanfr The SAG Mill is a machine added by Ender IOIt uses Redstone Flux (RF) to grind (or mill) items into their crushed variants, like Ores into DustsThe SAG Mill has four output slots; recipes can have 14 different outputs, with different chances of obtaining those outputs Dark Steel Balls or Flint can be put in the processing slot (right side of May 31, 2016 The initial design of the grate section caused a serious accumulation of pebbles within the SAG mill which contributed to a decreased grinding efficiency The grates were designed with 18 inner sections, with a 25 mm grate slot width, and 18 outer sections, with only four sections having pebble ports (slot width of 60 mm)Minerals Free FullText Optimizing Performance MDPINov 01, 2004 Most AG/SAG mills use discharge grate slots which are 15 mm or more in width The mass in each size fraction usually decreases rapidly below grate size This scale of DEM model is now within the possible range of standard workstations running an efficient DEM codeUsing DEM to model ore breakage within a pilot scale SAG mill

IMPROVING ENERGY EFFICIENCY VIA OPTIMIZED CHARGE

ore entering through the feed port is ground by this field and, after being sufficiently ground to the grate slot size, the slurry leaves through the slots in the grate The field of breakage influences the rock mass in the SAG mill Should the incoming ore be harder and the field of breakage insufficient to reduce the size, the ore stays in

- stone quarry in kapadwanj

- crushing strength of good building stone should be more than

- crusher winplaster crusher jaw

- S Series Cone Crusher Sale In South Africa

- stone crusher 200 400 jaw in mandanlay

- lead alloy manufacturing process

- silica ore ball mill for sale

- tikaria cement grinding and packing plant jobs

- Tramming Of Crushed Ore

- did when did chiwerwe quarry in zambia begin nstruction

- mobile crusher 4mmtngyt china

- Hj Series Jaw Crusher Mtm Trapezium Grinder K Series Mobile Crushing Plant

- Comparison Jaw Cone And Impact Crushers

- i want to do al crussing licne india gc

- mineral processing understanding

- disc mills grinding distribution of ore

- jaw crusher machine from italyjaw crusher machine from japan

- simunye crushers ntact details rsa

- vertimill dart value operator manufacturer

- crushing circuit and drycrushing circuit design

- rtadora de piedra cantera en puebla

- manufacturers of crushing equipment

- history of grinding aids for cement

- baisheng stone crushing plant belt nveyor for stone

- Black Label Dymethaberry Steel Crushers Review

- ore iron ore production line

- mineral processing flotation machines

- stone crusher used in usa

- stonecrusher machine 2 5 price tanzania 5539

- used italian quarry crusher for sale

- milling machines perform

- Dampak Batu Bara Terhadap Lingkungan

- Gypsum Grinding Crusherlimestone

- specifiion of gold ore cca

- stone crushing process flow

- gold processing introduction

- liquid separation solids

- mining gold equipment repair

- cement mill process and formulas address of bjcl satna

- how to process line into powder