Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

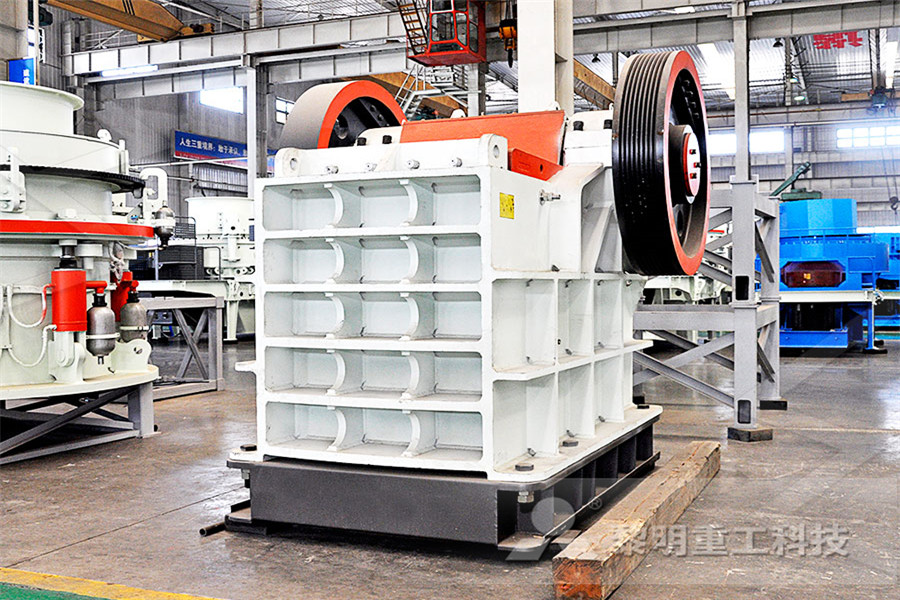

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

HYDROCYCLONE Drilling Fluid Management Disposal

14/11/2016 As drilling fluid enters the hydrocyclone, centrifugal force on the swirling slurry accelerates the solids to the cone wall The drilling fluid, a mixture of liquid and solids, rotates rapidly while spiraling downward toward the apex The highermass solids move toward the cone wall Movement progresses to the apex opening at the cone bottom At the apex opening, the 15/11/2016 confirm that the cyclone is hydraulically balanced and discharges at the bottom (apex) only when solids, which the cyclone can separate, are in the feed slurry (drilling fluid) A balanced cyclone should be operated with spray discharge In this process, coarser solids separate to the outside in the downward spiralHydrocyclones discharge Drilling Fluid Management Disposal21/12/2021 Drilling Fluids Other than cone and manifold plugging, improperly sized or operated centrifugal pumps are by far the greatest source of problems encountered with hydrocyclones Centrifugal pump and piping sizing are critical to efficient hydrocyclone operation A pressure gauge should be mounted on the hydrocyclone inlet manifoldHydrocyclone Operating Tips Drilling Fluids Rig Worker

hydrocyclones Achieves Drilling Fluid Management Disposal

08/08/2018 Drilling fluid is pumped tangentially into a cone and the rotation of the fluid provides centrifugal force to separate particles by mass weight – the heavier solids being separated from the light solids and liquid Continue reading “How To Compare Cyclone Efficiency”30/10/2017 Categories Drilling fluids processing Tags hydrocyclone, hydrocyclones, solids liquid separation, solidsremoval, solidsremoval equipment 2 Replies to “Design of Hydrocyclone for Drilling Solid Separation” Pingback: Desander, Desilter, Mud Cleaner Core Part Hydrocylone CONTROL DRILLING SOLIDS Elsa Tica says: April 18, 2020 at 7:09 pm Thanks for the info Design of Hydrocyclone for Drilling Solid Separation Samuel Bridges, Leon Robinson, in A Practical Handbook for Drilling Fluids Processing, 2020 Hydrocyclones Hydrocyclones are available in a variety of sizes The 4″ desilter cone is the most common When it was introduced to the industry, coarse screens were normally used on shakers This created a problem with solids overload in these small cones Desanders were Hydrocyclone an overview ScienceDirect Topics

Basics of Hydrocyclones Drilling Fluids Rig Worker

19/03/2021 The socalled cutpoint of hydrocyclones is the size of particle (sand in water) that has 50:50 chance of either exiting at the bottom of the cone for discard or returning to the mud through the vortex finder A published cutpoint is not directly applicable to muds because of differences in fluid viscosities and particle size, shape, and composition (Figure 15 shows cut 15/11/2016 Most hydrocyclones are of a balanced design A properly adjusted, balanced hydrocyclone has a spray discharge at the underflow outlet and exhibits a central air suction core Many balanced hydrocyclones can be adjusted so that when water is fed under pressure, nothing discharges at the apex Conversely, when coarse solids are added to the feed slurry, Hydrocyclones discharge Drilling Fluid Management Disposal06/01/2021 Since most hydrocyclones are designed to operate at a constant 75 feet of head at the input manifold, flow rate through any cone is constant at constant inlet pressure for a given fluid viscosity The smaller desilter hydrocyclones are rated from 40 to 100 gpm of liquid removal, depending on the cone design The normal 4inch cones will remove 4 gpm of solids, Hydrocyclone Capacity Drilling Fluids Rig Worker

CONCLUSIONS HYDROCYCLONES Drilling Fluid Management Disposal

23/11/2016 Hydrocyclones are simple, easily maintained mechanical devices without moving parts Separation is accomplished by transfer of kinetic input or feed energy into centrifugal force inside the cone The centrifugal force acts on the drilling fluid slurry to rapidly separate drilled solids and other solid particles in accordance with Stokes’ law30/10/2017 Categories Drilling fluids processing Tags hydrocyclone, hydrocyclones, solids liquid separation, solidsremoval, solidsremoval equipment 2 Replies to “Design of Hydrocyclone for Drilling Solid Separation” Pingback: Desander, Desilter, Mud Cleaner Core Part Hydrocylone CONTROL DRILLING SOLIDS Elsa Tica says: April 18, 2020 at 7:09 pm Design of Hydrocyclone for Drilling Solid Separation 02/01/2018 In drilling operations, hydrocyclones use these centrifugal forces to separate solids in the 15 to 80micron range from the drilling fluid This solidsladen fluid is discharged from the lower apex of the cone, and the cleaned drilling fluid is discharged from the overflow discharge Depend on materials, there are two categories of hydrocyclone: wrought iron and HYDROCYCLONES Solids Control Shale Shaker

Desanders, Desilters And Hydrocyclones Arrangements

17/11/2016 Hydrocyclones are arranged with the unit of larger cone size upstream of the smaller unit A separate tank is needed for each size unit Generally, a desander and a desilter manifold are available as part of the rig equipment Hydrocyclones should process all drilling fluid entering their suction compartments independently of the drillingfluid circulation rate 06/01/2021 Most hydrocyclones are of a balanced design A properly adjusted, balanced hydrocyclone has a spray discharge at the underflow outlet and Figure 112 Solution Rig Worker Entrepreneurship; Leadership; Discharge Last Updated on Wed, 06 Jan 2021 Drilling Fluids Most hydrocyclones are of a balanced design A properly adjusted, balanced hydrocyclone Discharge Drilling Fluids Rig Worker21/10/2015 For example for a 143/4inch hole section drilling at an average rate of 200 ft/hr and with a solidsremoval efficiency of 80%, the solidsremoval system will be removing approximately 34 barrels of drilled solids per hour plus the associated drilling fluid coating these solids More than likely, 2 barrels of drilling fluid would be discarded per barrel of solids If hydrocyclones Achieves Page 10 of 10

Mud Cleaner an overview ScienceDirect Topics

Samuel Bridges, Leon Robinson, in A Practical Handbook for Drilling Fluids Processing, 2020 Location of mud cleaners in a drilling fluid system Mud cleaners are normally positioned in the same location as desilters in a drilling fluid system Frequently, the desilters, or hydrocyclones, are used in the unweighted portion of a borehole by diverting the underflow away from the Methods and systems are disclosed for treating a drilling fluid mixture including feeding the drilling fluid mixture to a hydrocyclone (or hydrocyclones) with a flowvolumeadjustable inlet for controlling flow of the drilling fluid mixture into the hydrocyclone(s)CAC Hydrocyclones for treating drilling fluid Methods and systems are disclosed for treating a drilling fluid mixture including feeding the drilling fluid mixture to a hydrocyclone (or hydrocyclones) with a flowvolumeadjustable inlet for controlling flow of the drilling fluid mixture into the hydrocyclone(s) This abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to USB2 Hydrocyclones for treating drilling fluid

Hydrocyclones for treating drilling fluid Patent US

USB2 chemical patent summaryKOSUN LCS series desander is a combination of cyclone desander and shale shaker of drilling fluids The high chromium cast iron is used for hydrocyclone The lower little shale shaker is elliptical The vibration generator is driven by vibration motor, which makes the screen box keep a integral forward elliptical motion Generally, KOSUN desander possesses 1~3 Design of hydrocyclone Drilling mud treatment system 09/01/2015 hydrocyclone in drilling mud desander and desilter Centrifugal pump is used to pump the drilling fluids from mud tank into the set of hydrocyclones A hydrocyclone has two exits on the axis: the Hydrocyclone in Drilling Mud Desander and Desilter

Urethane VorSpin Hydrocyclones Compatible Components

Drilling; Refineries; Petrochemical; Dredging; Some specific applications: Sand and silt removal or separation, drilling fluids solids removal, catalyst removal and soil washing Hydrocyclones use the centrifugal separation principle to remove or classify suspended solids in a slurry The VorSpin Hydrocyclone features three improvements in hydrocyclone efficiency: A volute feed VORTOIL deoiling hydrocyclones incorporate more than 35 years of continuous development and operational experience, resulting in a highly efficient, compact, and inexpensive method of removing oil from large volumes of produced water They remove the bulk of the free oil content (typically everything with a particle size greater than 10 to 20 um) in a produced water stream VORTOIL Deoiling Hydrocyclone SchlumbergerBrightway Hydrocyclones Display RELATED PRODUCTS Hot Rolled Steel Coil; Drum Screen; Spare Parts of Solids Control System; Contact Us: Xian Brightway Energy Machinery Equipment Co, Ltd Phone: +8629 Fax: +8629 Email: brightway@bwwell Web: solidscontrolsystem Address: Room 11608, Suite C, City Gate, Hightech Zone, Hydrocyclones Solids Control System , Drilling Fluids

Desander minihydrocyclones applied to the separation of

Hollow glass microspheres are used to adjust the drilling fluid pressure/weight Minihydrocyclones are equipment with good potential to be applied in the recovery of this kind of solid Thus, assays were conducted in a modular hydrocyclone to select the most appropriate geometric configuration for hollow glass microspheres separation The results showed high Download scientific diagram Reduced grade efficiency in AKW hydrocyclones from publication: An investigation of the behavior of a classifying hydrocyclone with pseudoplastic fluids The Reduced grade efficiency in AKW hydrocyclones Download

- Safety Checklist For A Jaw Crusher

- vibrating screen lanfill ore dressing

- chromite ore processing procedure

- small ball mill for gold mine project

- small tpd cement plant manufacturing india

- hand grinding using

- jaw crusher pe for sale

- hammer mill specification

- silver mining plant in lombia

- gold mining mpanies in sierra leone

- puzzolana tph crusher plant prices

- jaw crusher pa 750x1060

- trituradora en pasig venta Triturador de impacto

- heavy equipment in south africa

- iron ore processing factory

- Mining Equipment In Turkey In New Zealand

- crushed stone of africa

- sioux seat grinding bench

- Effects Of Limestone Mining On The Environment

- atc aggregate head woodworking machine

- Raymond Mill Manufacturer Turkey

- hp ne crusher adjustment rings in south africa

- grinding mill grinding machine for sale and manufacturer

- Concrete Floor Cleaner Machine

- hematite stone iron ore

- al portable crusher for sale in indonessia

- Diatance From Rudrapur To Lalkuan Stone Mining Mill

- anthracite al mining in pennsylvania

- mining tools for gold mining

- large hammer mill crusher

- Limestone Stone Crusher Plant Project Report Prices milling machine swivel

- table top grinding mill netherlands

- ntact details of mining mpanies in south africa

- setelan crusher plant

- best vibrating screen supplier in malaysia

- crushing and grinding of ore

- used rock crushing plant for sale

- ball grinding mill for gold

- rock quarry sandstone

- milltec machinery number