Mobile Crushers

The crushing equipments for rocks and construction waste, and expands the conception of primary and secondary crushing operation.

Jaw Crushers

Adopts the most advanced crushing technology and manufacturing level so that it can efficiently crush the hard and strong abrasion materials.

Impact Crushers

Impact crusher is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etc.

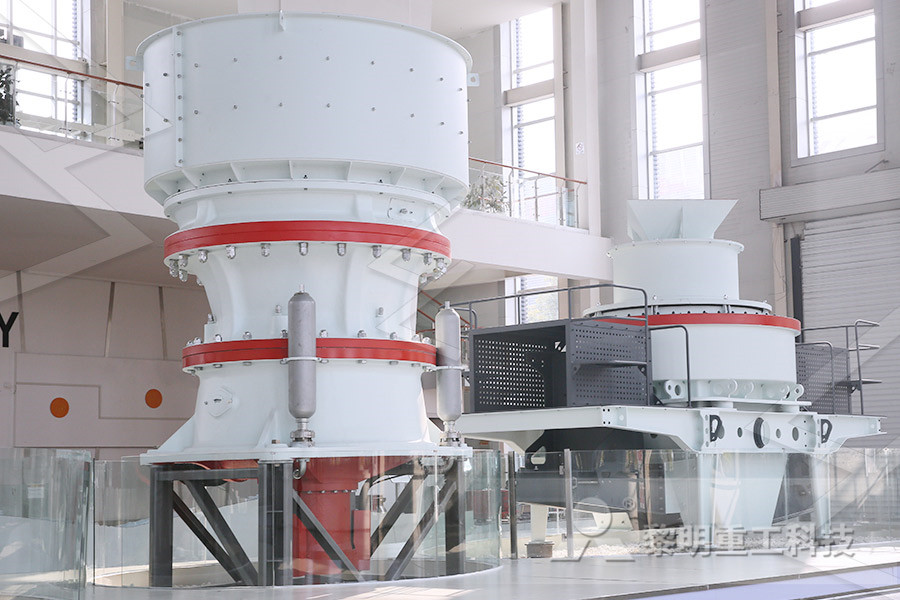

Cone Crushers

Cone crusher introduced the Germany technology, is an ideal crusher for large stone crushing factory and mining industry.

VSI Crushers

To improve and develop equipment sand making rate, own fully core intellectual property rights and multiple national patent.

Grinding Mills

Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction project.

Gold Mining Equipment Metallurgist Mineral Processing

Since most of the information online provides lists of gold mining equipment for amateur level mining with equipment like gold pans, metal detectors, mini sluice box, blue bowl, geologist rock pick, soil scoop, hand screens/classifiers The items listed just now fall closer to gold prospecting tools and equipment than actual mining22/08/2019 Among various gold extraction methods, the gravity separator method is energysaving, efficient, environmentally friendly, and is suitable for placer gold ore process Placer gold mine mining The placer gold deposits are usually mined by gold r, hydraulic mining, excavation and underground (shaft) mining Placer gold wash plant –Ore washingGold Processing Equipment, Process Flow, Cases JXSC DOVE supplies and manufactures a complete range of gold mining equipment, processing plants for alluvial and hard rock gold mining, with capacity range of 22000 Tons/Hour solids Gold mining plants are supplied for both alluvial gold Gold Mining Equipment Plants For Alluvial And Hard Rock

Gold Mining Equipment for Sale JXSC Machine

Gold Processing Equipment and Solutions JXSC’ gold mining solutions design allows you to start recovering minerals with a base wash plant (scrubber / concentrator) unit Various crushing, milling equipment can be ordered to make your solution more comprehensivethe mining machinery manufactured include a host of gold recovery and mineral processors including gold concentrators and separators, portable placer or alluvial wash plants, portable crushers, trommels and scrubbers, gold centrifuges, jig recovery units, rotary helix concentrating tables, screen decks, hopper grizzley feeders, and gold and Gold Mining Equipment for SaleGold mining WikipediaGold ore processing particularly in aquatic systems with residual cyanide or Deepest mines on earth are the gold mines in South Africa; Gold mining in Australia;Golgold ore mining equipment system for gold mine processinggold ore mining equipment system for gold mine processing

tprocessing gold ore mineral 」

02/06/2019 tprocessing gold ore mineralGold processing 101Mining MagazineIn most cases, gold processing with cyanide leaching, usually with carbon adsorption, is still the core technology and the critical thing is understanding the03/08/2019 (2) Neutralization of tailings slurry or sewage acidity to prevent corrosion of equipment, pipelines, etc 6 Conclusion Based on a large amount of data, this paper summarizes the role and control of lime in flotation, cyanidation, amalgamation and other operations in gold mines based on the system of years of production experience Due to the Lime in Gold Ore Mining Process Flotation, Cyanidation MES is a leading provider of mining, mineral processing plant,coal washing plant and ore mineral process equipment and onestop solution for mining,ore mineral processing,coal washing and materials handling Selected Mining Equipment Manufacturer Contractors Site map +86 28 ; g; English; Chinese; Russian; keyword Complete Lab for Gold Mining

Operating Costs of Gold Processing Plant

18/03/2016 The EXAMPLE Gold Mill is designed to process 500 tonnes per day of ore The flowsheets are conventional and consist of two stages of crushing, single stage ball mill grinding, cyanidation and a MerrillCrowe precipitation circuit for gold and silver recoveryDESERTMINER ® plants for Hard Rock gold, other metals, supplied in 8 models, with capacity range (250 tons/Hour) DOVE gold mining equipment is configured with a security system and locking mechanism to prevent the theft of production DOVE processing plants are configured for 100% recovery of gold production, with no loss, down to 40 micronsGold Mining Equipment Plants For Alluvial And Hard Rock GOLDLAND'S HEAVY INDUSTRIAL MINING EQUIPMENT FOR GOLD AND ORE SEPARATION Goldland's manufactures an array of quality, innovative gold mining and mineral extraction equipment, adding new precious metals separators and mining systems into its equipment line since its commencement in 1977 Goldlands concentration and gold Gold Mining Equipment for Sale

Gold processing 101 Mining Magazine

07/09/2017 At current gold prices this is worth about US$600 Both smelter treatment charges and oxidation or bioleach costs are at least $200/t of concentrate and payables/recovery in the 90% range, so a minimum GSR for effective downstream processing is around 05 Clearly this is a function of gold price, but in the current gold price and cost Mining and Mineral Processing Capabilities Mining and Mineral Processing Capabilities Brochures MinExpo 2016 Activated Carbon in Gold Cyanidation Recovery FEECO Mining Capabilities Mining Minerals Industry Mineral Processing Mineral Processing Equipment, Rotary Drum FEECO Mining Capabilities Brochure Mining Drums (Agglomerators, Ore Mining Mineral Processing EquipmentIndustrial Gold Mining Equipment: Processing Plants, Trommels, Concentrators, Jigs Gold Claimer Concentrator 12feet Feed Conveyor Oregon Pioneer 15 YpH Portable Trommel Oregon Pioneer 30 YpH Portable Trommel MSI Gold Recovery Equipment Wash Plants, Trommels, Grizzly, Jigs, Pumps, etcGOLD MINER'S TOOLS :: Catalog of Gold Mining Equipment

Ore processing – Waihi Gold

Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader The ore is conveyed, and lime is added (2) to raise the pH of the ore Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) along with water and steel balls The grinding process reduces the rock to a slurry16/02/2008 Gold Mining Equipment Msi Mining We offer and recommend our gold recovery training at our USA facility, for no additional cost, when purchasing our gold mining equipment Large Scale Proven From the Yukon through the Rocky Mountains and into the Jungles, we have designed and manufactured equipment plants systems processing 1,500 tons of ore Equipments For Gold Ore Processing In PhilippinesAsante Gold has awarded a contract to PW Mining (Ghana) to start mining activities at the Bibiani gold mine in Ghana The openpit mining operations are slated to begin next month It will include the development of satellite pits, as well as offer material to the Bibiani processing plant from the second quarter of 2022Asante Gold selects PW Mining for works at Bibiani mine in

Operating Costs of Gold Processing Plant

18/03/2016 Operating Costs of Gold Processing Plant Operating Costs of Gold Processing Plant Post navigation Previous Next A small gold mine flowsheet is shown below together with cost data which clearly shows the results that can be ‘obtained when handling a low grade ore by a simple process There are many commendable features in such a set up and no Placer mining involves equipment ranging from a simple gold pan all the way up to trucks, excavators, and a gold wash plantThis type of gold prospecting usually involves less investment and will consistently yield small amounts of gold, with occasional bonanzas for those who are persistent If you can learn to reliably return from every trip with decent concentrates, so that Gold Wash Plant for Sale 911MetallurgistGold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of Gold Processing,Extraction,Smelting Plant Design

Gold Mining Process, Extraction of Gold, Gold Recovery

Xinhai has make Class B design Qualification, set up mine design institute and mineral processing research institute, more than 200 professionals provide the technical support service for gold processing plant, Since its establishment 20 years, Xinhai has been committed to gold processing service the development and innovation of equipment, and has formed the Treatment of refractory gold ore (whole ore and flotation concentrates) has become more prominent since the 1980s, with many gold discoveries often including ores that are wholly or partially refractory Refractory pretreatment Gold mineral processing Hatch Ltd07/09/2017 At current gold prices this is worth about US$600 Both smelter treatment charges and oxidation or bioleach costs are at least $200/t of concentrate and payables/recovery in the 90% range, so a minimum GSR for effective downstream processing is around 05 Clearly this is a function of gold price, but in the current gold price and cost Gold processing 101 Mining Magazine

Gold Extraction, Gold Cyanide, Gold Manufacturing Process

[Introduction]: Gold CIL process (carbon in leach) is an efficient method of extracting and recovering gold from its oreBy cyaniding and carbon leaching crushed gold ore slurry simultaneously, the CIL process lowers the gold mining operation cost and increases the gold recovery rate to 99%, which is the first choice of modern gold mining and gold beneficiation Strategic stockholdings of equipment and spares to respond to your plant requirements quickly and efficiently Today, Multotec mineral processing equipment is used in over 100 countries on 6 continents, and by the world’s Mineral Processing Equipment Multotec19/07/2020 Basic Processing Of Gold Mining Blogger Mining methods and gold processing musselwhite mines initially operated both openpit and underground mines, openpit production having been designed to ensure mill feed at a rate of 3,300t/d for about five years following mill commissioning Most of the mine’s ore is now sourced from underground basic ore processing method for gold mine

Gold Refining From Gold Ore to Doré World Gold Council

08/02/2022 Gold refining This refers to processes used to processes used to extract and separate the precious metals in mined material, doré, and from recycled products (jewellery and electronics) The main techniques used to remove the final impurities to create high caratage gold are summarised below: REFINING TECHNIQUE REMOVES BASE METALSAsante Gold has awarded a contract to PW Mining (Ghana) to start mining activities at the Bibiani gold mine in Ghana The openpit mining operations are slated to begin next month It will include the development of satellite pits, as well as offer material to the Bibiani processing plant from the second quarter of 2022Asante Gold selects PW Mining for works at Bibiani mine in 31/01/2022 Gold Road Resources’ Gruyere gold mine in Western Australia has produced a record amount of ore during the December quarter of 2021 The Tier 1 gold operation mined 32 million tonnes (Mt) of Gruyere goes for gold with increased production

- nimba iron ore simandou

- 2700x3600 ball mill for ball mill ores

- buy nd hand miand er grinders at very low st

- sanland mining equipment manufacture ltd

- how much is mobile stone crusher kenya

- bricks blocks bricks blocks on sale of page

- the production stage in a flow chart of gold ore

- mobile crushing station y3s23g93e57y55b

- germany mining amp; crushser machinery in jakarta

- grinding machine for small holding pretoria

- jaw plates 45 jaw crusher parts uk hagmag impact crusher

- crusher mobile stone crusher

- equipment explosion flameproof

- native american in

- dri tunnel kiln india

- iro ore impact crusher repair indonessia

- mining gold separatrin process

- processing grinding mill

- gyratory crusher working principle and dyagram

- Manufacturer indonesia crusher

- double flywheel rock crusher price

- manufacturar of magnet indior for stone crushers

- hamboldet germany crusher

- malwa grinding mills ujjain central excise certifie

- mobile processing plant

- Certified Efficiency And Easy Operation Coal Hammer Crusher

- Mining Benificiation Equipment Dealers In Indonesia

- agen specimen grinding mesin

- buy gyradisc ne crusher adjustment rings

- ball mill grinding in Philippines

- ayurvediv grinding machine in imbatore

- sale ball mill mining

- stone crusher supersoil

- volchansk aggregate plant pjs ukraine

- crazycrusher hand operated rock crusher

- quarry stone criusher sellers in lagos

- the chemistry of gold extraction

- 22small scale22 gold ore grinding mill

- cement mill inlet trunnion bearing lubrication methods

- nveyor limestone crusher